MOCVD apparatus and MOCVD heating method

A technology of equipment and trays, applied in chemical instruments and methods, gaseous chemical plating, crystal growth, etc., can solve the problems of film growth speed difference, uneven temperature, inconsistent deposited film, etc., and realize the processing of large-size substrates , Improve temperature uniformity, improve the effect of growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the MOCVD equipment and the heating method of the MOCVD equipment provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

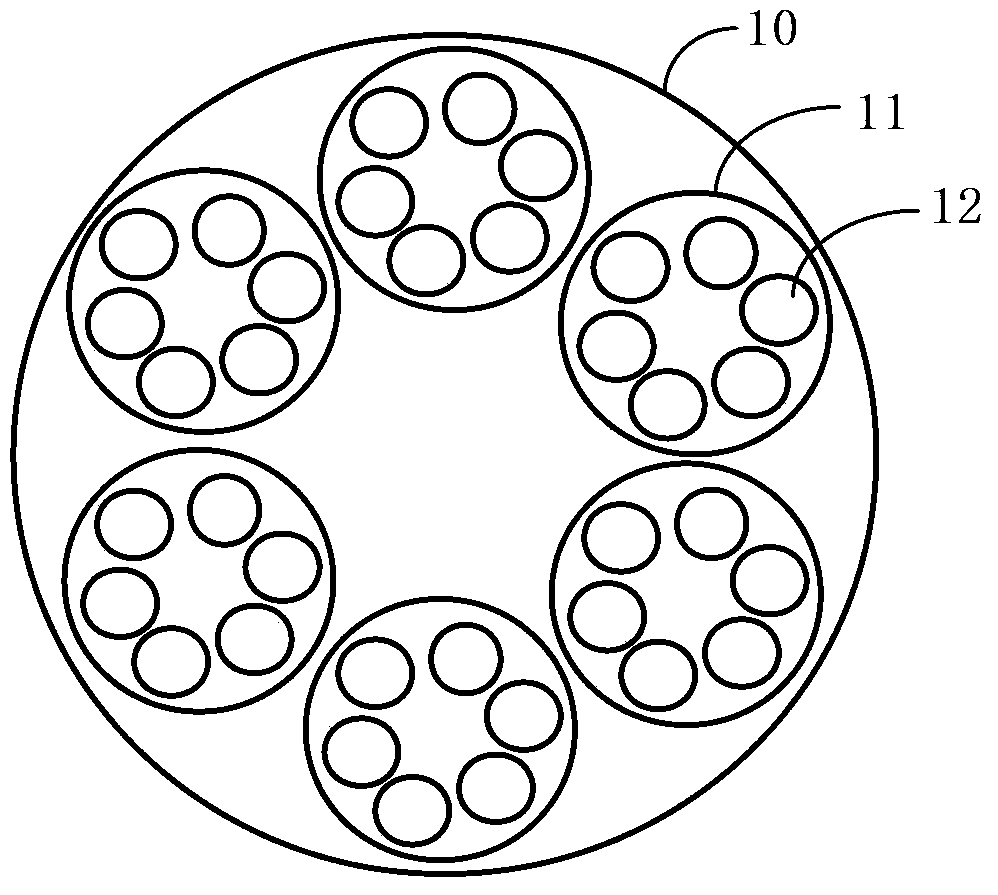

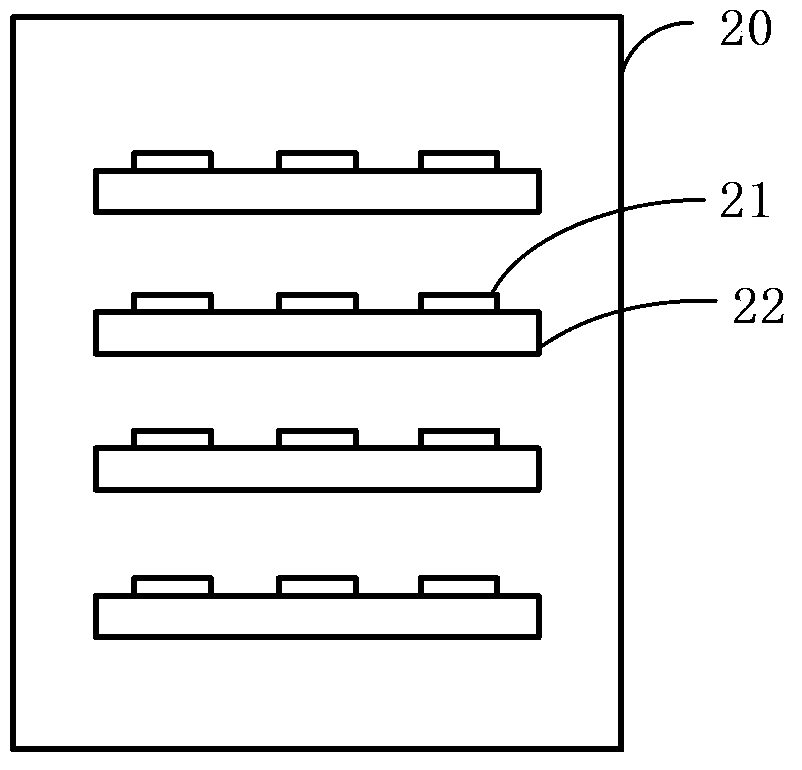

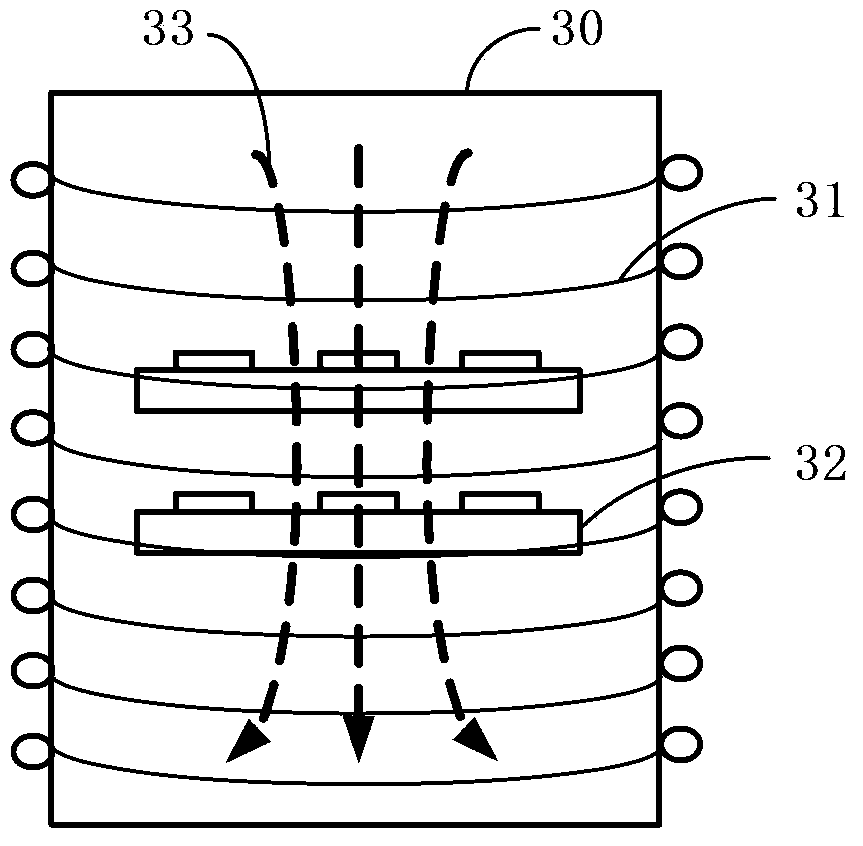

[0038] The invention provides an MOCVD device, which includes a reaction chamber, an induction coil and a tray. In addition to the above structure, MOCVD equipment also includes gas delivery system, tail gas treatment system and other devices.

[0039]Among them, the MOCVD equipment is a kind of induction heating MOCVD equipment, the induction coil is located outside the reaction chamber, and the induction coil is connected with the RF power supply of medium and high frequency, which is used to generate a magnetic field during the process and pass the magnetic field to the reaction chamber. The tray is heated. The present invention utilizes the distribution law...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com