Microwave-heated rotational molding die equipment and method for manufacturing rotational molding product

A technology for microwave heating and rotomolding molds, applied in the field of mold manufacturing rotomolding products and rotomolding molds, can solve the problems of high process difficulty, high operating costs, low mold precision, and long production cycles, and achieves improved heating automation and temperature. Control accuracy, less heat dissipation from equipment, and improved heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

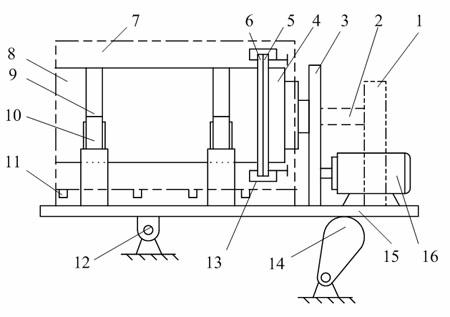

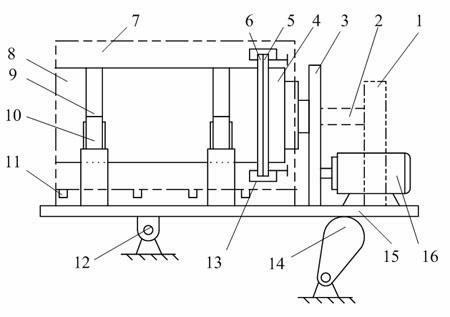

[0022] As shown in the figure, the equipment of the present invention includes a microwave source 1, a microwave transmission tube 2, a transmission device 3, a mold upper mold 4, an upper mold flange 5, a lower mold flange 6, a movable constant temperature heating box 7, and a mold lower mold 8 , Card slot 9, support roller 10, thermometer 11, base hinge 12, mold fixture 13, base swing mechanism 14, base 15, motor 16.

[0023] The joints of the lower mold 8 of the rotomolding mold are stretched and prepared by using the metal plate dieless single-point progressive forming technology, and then the joints are assembled into a whole lower mold by welding, and the upper and lower molds of the mold are clamped by the mold clamp 13 to form the whole mold , make the flange 6 of lower mold 8 with flat steel bar and be welded to around the upper mouth of lower mold 8, adopt same method to make upper mold 4 and upper mold flange 5.

[0024] The support roller 10 is fixed on the base 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com