Making method of ready-to-eat shiitake mushrooms

A technology of shiitake mushrooms and mushroom stems, which is applied in the direction of food ingredients as taste improvers, confectionery, and confectionery industry. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

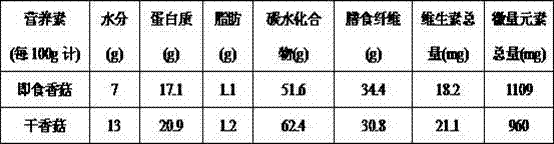

Image

Examples

Embodiment 1

[0020] a. Selection: select fresh shiitake mushrooms with no deterioration, complete shape and uniform size, and remove the stems;

[0021] b. Cleaning: Rinse repeatedly with clean water to remove dirt such as sediment and sawdust, and drain;

[0022] c. Freezing: Drain the surface liquid of the soaked shiitake mushrooms and cool them down, then freeze them at -18°C for 24 hours;

[0023] d. Vacuum microwave drying: place the frozen shiitake mushrooms directly in a vacuum microwave dryer for vacuum drying; the process is divided into three stages, the total drying time is 30min, and the vacuum degree is -0.090MPa; in the first stage, microwave The power density is 9w / g, the drying time is 7min, and the drying temperature is 70°C; the second stage, the microwave power density is 7w / g, the drying time is 10min, and the drying temperature is 55°C; the third stage, the microwave power density is 4w / g, and the drying time is 13min. Drying temperature 45°C;

[0024] E, seasoning: ...

Embodiment 2

[0029] a. Selection: select fresh shiitake mushrooms with no deterioration, complete shape and uniform size, and remove the stems;

[0030] b. Cleaning: Rinse repeatedly with clean water to remove dirt such as sediment and sawdust, and drain;

[0031] c, blanching: cook the shiitake mushrooms, drain, cool, the solution components (by weight) for cooking shiitake mushrooms are: 100 parts of water, 0.5 parts of salt, 0.2 parts of citric acid, 0.06 parts of ascorbic acid, and the blanching time is 2min;

[0032] d. Freezing: Drain the surface liquid of the soaked shiitake mushrooms and cool them down, then freeze them. The freezing temperature is -18°C, and the freezing time is 24 hours;

[0033] e. Vacuum microwave drying: place the frozen shiitake mushrooms directly in a vacuum microwave dryer for vacuum drying; the process is divided into three stages, the total drying time is 30min, and the vacuum degree is -0.090MPa; in the first stage, microwave The power density is 9w / g,...

Embodiment 3

[0039] a. Selection: select fresh shiitake mushrooms with no deterioration, complete shape and uniform size, and remove the stems;

[0040] b. Cleaning: Rinse repeatedly with clean water to remove dirt such as sediment and sawdust, and drain;

[0041]c, blanching: cook the shiitake mushrooms, drain, cool, the solution components (by weight) for cooking shiitake mushrooms are: 100 parts of water, 0.5 parts of salt, 0.2 parts of citric acid, 0.06 parts of ascorbic acid, and the blanching time is 2min;

[0042] d. Dipping: put the cooled shiitake mushrooms in a vacuum sugar dipping machine, add auxiliary materials, and carry out vacuum dipping at a temperature of 50°C and a vacuum of -0.07MPa for 15 minutes. The components of the dipping solution (by weight) For: 100 parts of water, 10 parts of maltodextrin, 5 parts of maltose, 400 parts of shiitake mushrooms;

[0043] e. Freezing: Drain the surface liquid of the soaked shiitake mushrooms and cool them down, then freeze them at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com