System for preparing graphene with purification and optical microwave reduction

A graphene and microwave technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of equipment corrosion, increased cleaning difficulty, low efficiency, etc., to achieve long equipment life, easy use and transportation, High purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

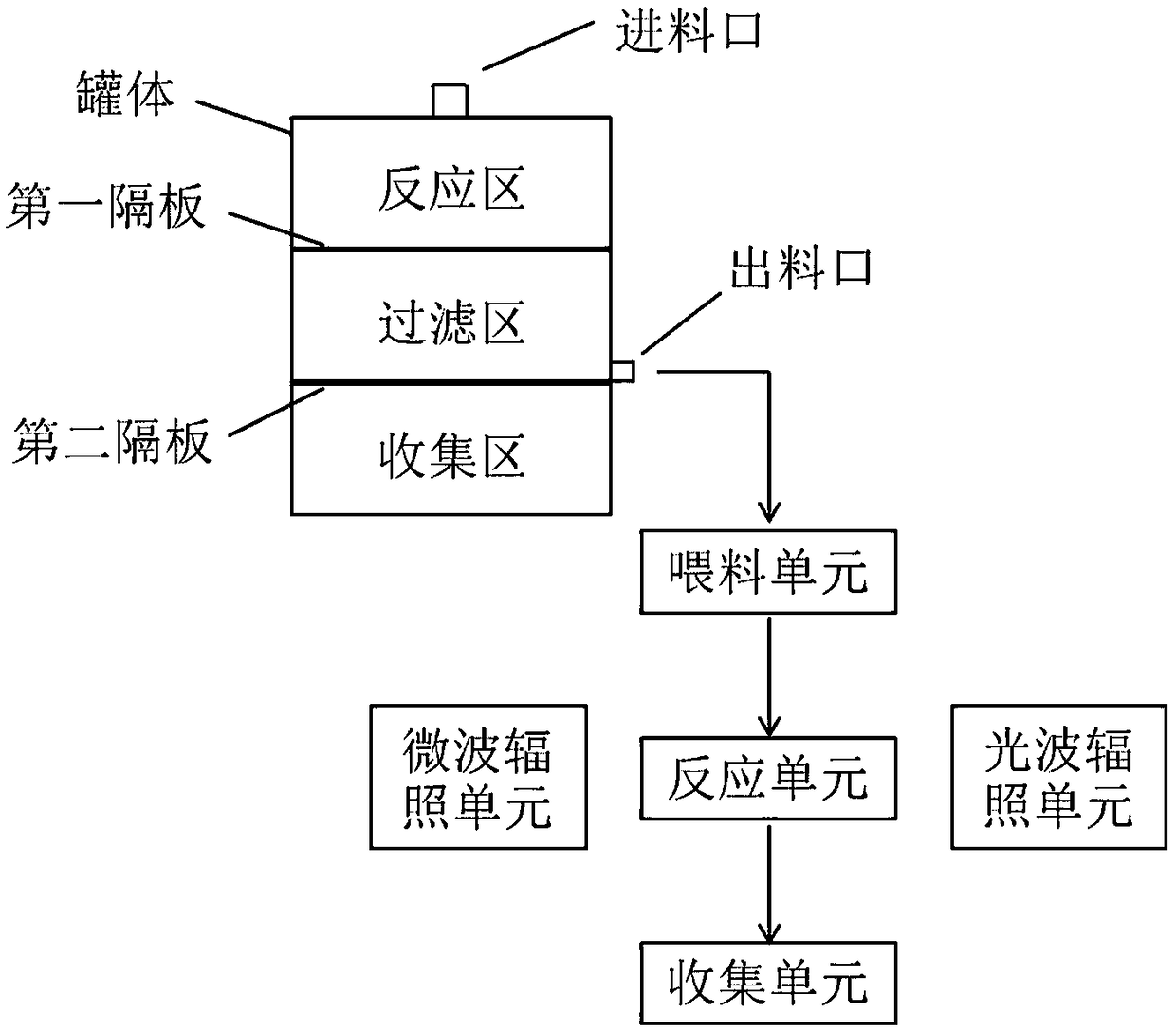

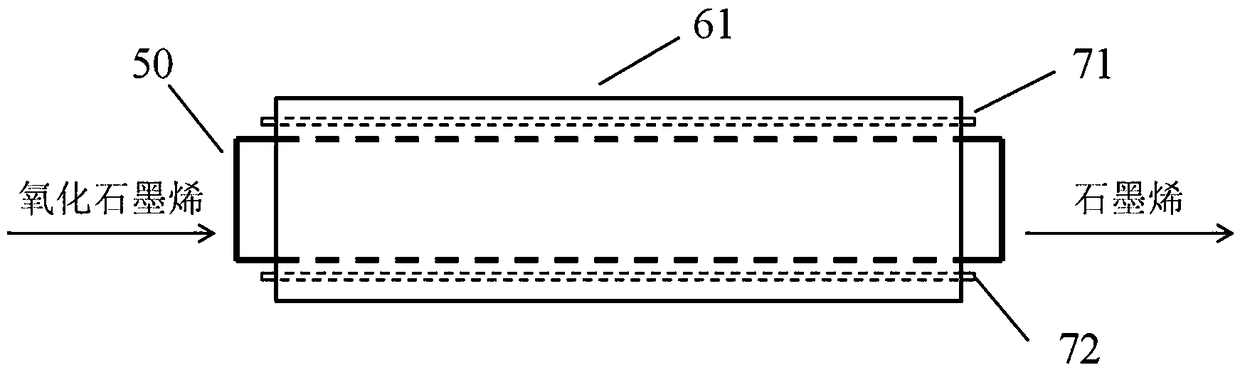

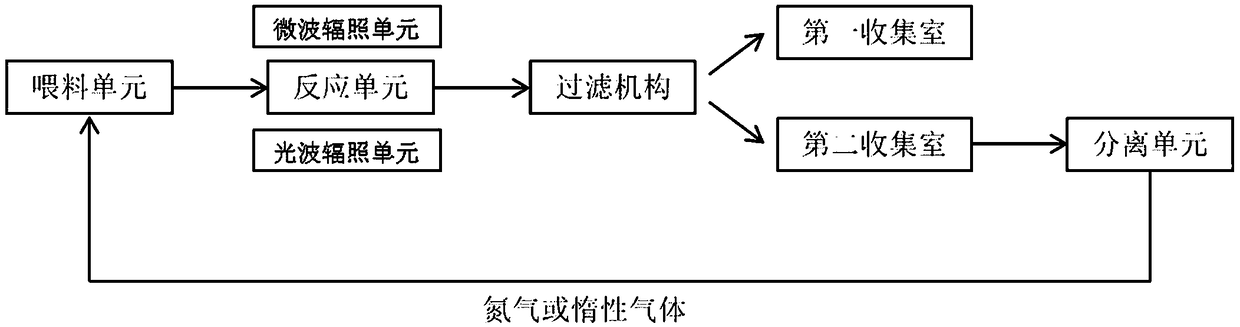

[0036] Hereinafter, the system for preparing graphene through purification and photomicrowave reduction of the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0037] Graphene oxide can be used as a raw material to prepare graphene, and impurity ions are often combined in graphene oxide, which leads to low purity of graphene oxide, and the produced graphene often has a higher impurity content. The heating method in the existing reduced graphene oxide device often adopts the traditional heating method, and the traditional heating method is to first transfer the heat to the surface of the object through heat conduction, convection, heat radiation, etc., and then gradually increase the temperature of the center of the object through heat conduction. High, it needs a certain heat conduction time to make the central part reach the required temperature, and the time required for objects with poor thermal conductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com