Novel boundary lubrication protective agent production device and production method of protective agent

A technology of boundary lubrication and production equipment, applied in the direction of lubricating composition, chemical/physical/physical-chemical process of applied energy, etc., can solve problems such as insufficient heating method, and achieve easy automation, improved production environment, and continuously adjustable power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

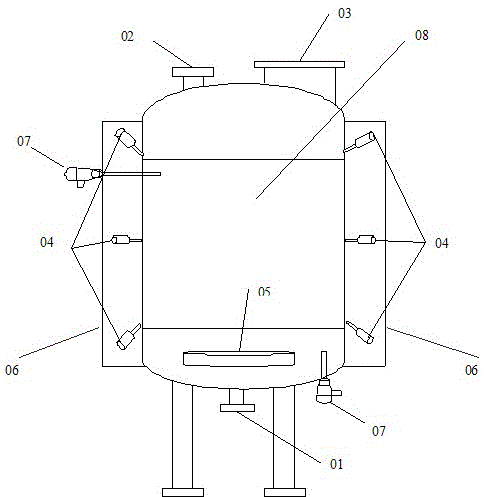

[0034] Embodiment 1: the novel boundary lubricant protection agent production equipment as shown in the figure, comprises blending still, and described blending still is made of still body and the inlet and outlet that are arranged on kettle body 8, and described inlet The feed port is a base oil feed hole 2 and a manhole / additive feed hole 3, the base oil feed hole 2 and the manhole / additive feed hole 3 are arranged at the upper end of the kettle body 8, and the discharge port is boundary lubrication Protective agent discharge hole 1, which is located at the lower end of kettle body 8. The kettle body 8 is provided with a temperature control probe 7, and the outside of the kettle body 8 is provided with a microwave generator, and the microwave generator 4 guides microwaves into the kettle body 8 through a microwave guide tube; A stainless steel plate 6 for microwave shielding is provided, and the stainless steel plate 6 can shield microwaves to prevent microwaves from leaking...

Embodiment 2

[0041] The equipment and method of this embodiment are basically the same as those of Embodiment 1, the difference being that the spatial layout of the microwave generator in this embodiment is that three microwaves are respectively arranged on the upper, middle and lower sides of the left and right sides of the kettle body. generator.

[0042] The production method of boundary lubricant protection agent is as follows:

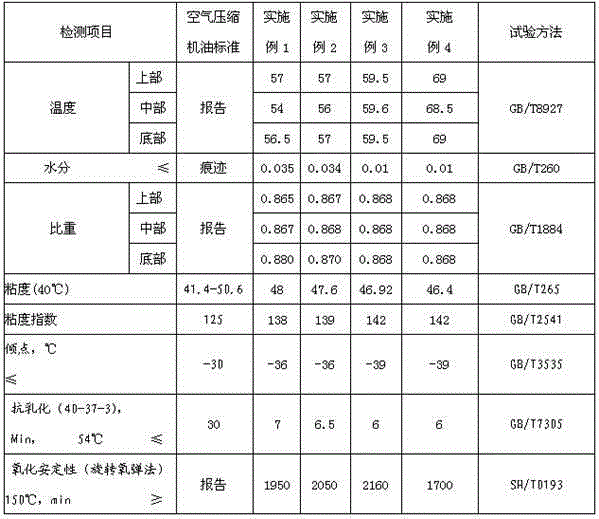

[0043] Add base oil and additives into the tank body through the base oil feed hole and additive feed hole, start the micro generator through the controller and adjust the microwave power to 6000 to 6500W, the microwave radiation time is 12 to 17min, and the pulse pressure is 1kgf to 1.5kf, the pulse frequency is 3 to 5 times per minute, and the impact mixing time is 18 to 25min; and the opening and frequency of the solenoid valve are controlled through the PLC panel, and the pressure and flow rate of the high-pressure air distribution plate at the bottom of t...

Embodiment 3

[0045] The equipment and method of this embodiment are basically the same as those of Embodiment 1, except that the spatial layout of the microwave generator in this embodiment is arranged on the left, right, front and rear sides, middle and bottom of the kettle body. Three microwave generators.

[0046] The production method of boundary lubricant protection agent is as follows:

[0047]Add base oil and additives into the tank body through the base oil feed hole and additive feed hole, start the micro generator through the controller and adjust the microwave power at 6500 to 7300W, the microwave radiation time is 18 to 23min, and the pulse pressure is 1.8kgf to 2.2kf, the pulse frequency is 4 to 6 times per minute, and the impact mixing time is 28 to 35 minutes; and the opening and frequency of the solenoid valve are controlled through the PLC panel, and the pressure and flow rate of the high-pressure air distribution plate at the bottom of the reaction mixing kettle are contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com