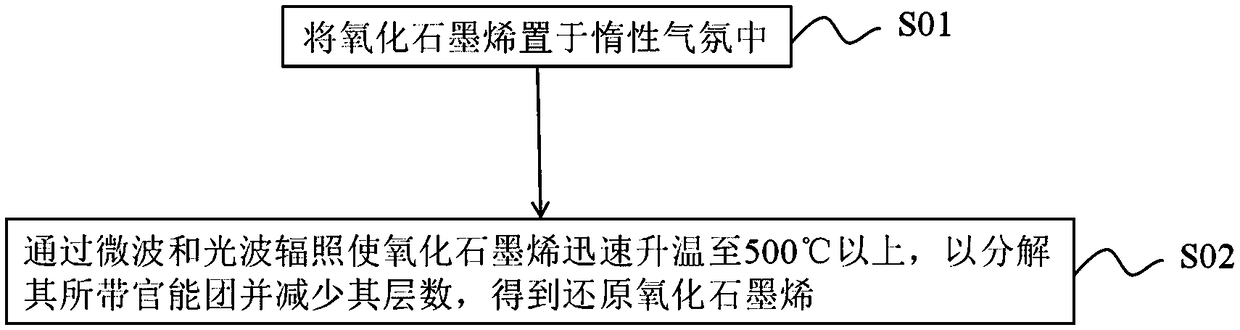

Method for reducing graphene oxide by optical microwaves

A graphene and microwave technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of increased cleaning difficulty, increased ash content of products, equipment corrosion, etc., and achieves high reduction efficiency, fast heating speed, no The effect of thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

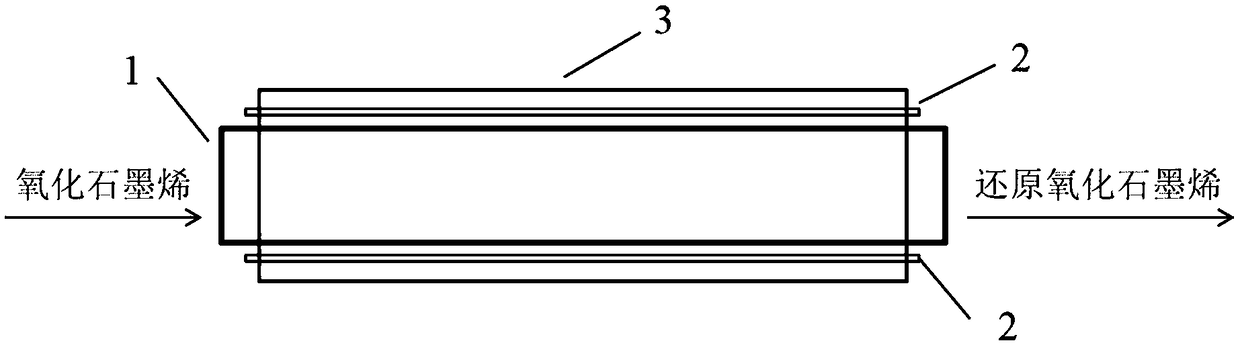

Method used

Image

Examples

example 1

[0046] Example 1 (blank comparison example)

[0047] Graphene oxide is used as a raw material, the number of layers of graphene oxide is 30, and the weight ratio of functional groups in graphene oxide is 0.82%.

[0048] The graphene oxide is reduced by microwave to obtain the reduced graphene oxide. Wherein, the microwave frequency is 5 GHz, and the microwave treatment time is 8 min.

[0049] After testing, the number of layers of the reduced graphene oxide is 10, the weight ratio of functional groups is 0.27%, and the removal rate of functional groups is 67%.

example 2

[0051] Graphene oxide is used as a raw material, the number of layers of graphene oxide is 30, and the weight ratio of functional groups in graphene oxide is 0.82%.

[0052] The graphene oxide is reduced by the optical microwave reduction method of the present invention, and the reduced graphene oxide is obtained. Among them, the frequency of microwave is 5GHz, and the frequency of light wave is 5×10 13 Hz, light wave and microwave treatment time is 5min.

[0053] After testing, the number of layers of reduced graphene oxide is 7, the weight ratio of functional groups is 0.04%, and the removal rate of functional groups is 95.1%.

[0054] In summary, the optical microwave reduction graphene oxide of the present invention has the following advantages:

[0055] (1) Fast heating speed

[0056] Conventional heating (such as flame, hot air, electric heating, steam, etc.) uses heat conduction, convection, and heat radiation to first transfer heat to the surface of the object to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com