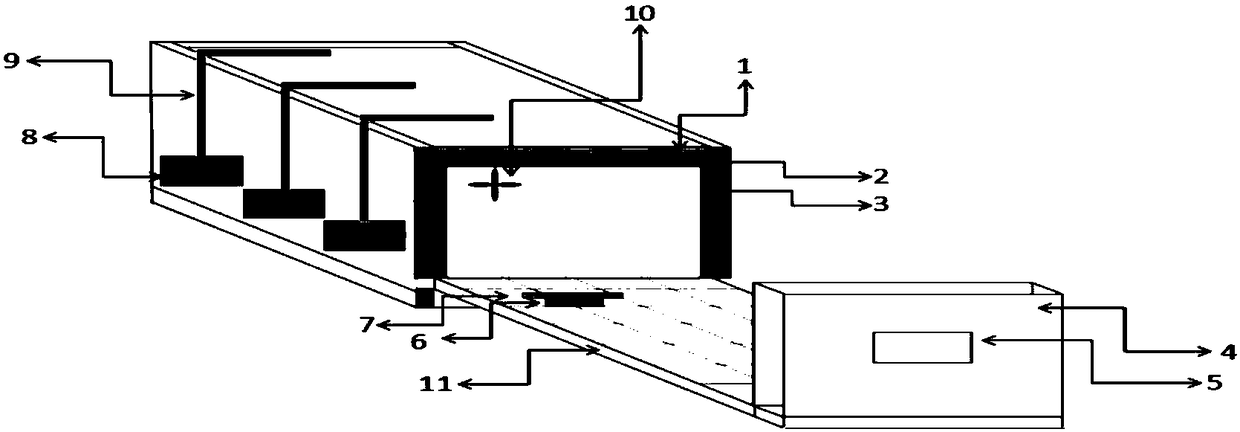

Microwave hot bending kiln and microwave heating hot bending glass ceramic preparing method

A technology of glass-ceramics and microwave, which is applied in glass molding, glass re-shaping, glass manufacturing equipment, etc., can solve the problems of uneven temperature distribution in the furnace, unstable heat source distribution, long time consumption, etc., and shorten the heating time , the overall quality improvement, and the effect of improving the crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Hot bending glass-ceramic annealing plate

[0022] Place a glass annealed plate with a specification of 1050mm*1050mm*10mm on a curved body with a diameter of 800mm for hot bending; control the microwave output power to heat the plate to 760°C after 10 minutes, and then keep the plate temperature at 755°C~ Between 765°C, last for 40 minutes, and perform hot bending. After the hot bending is completed, the plate is cooled to 620°C after 10 minutes, kept at a temperature of 5 minutes, and cooled to room temperature after 80 minutes to obtain a glass-ceramic hot bent plate.

[0023] According to the statistics of the process, the production time of the microwave bending kiln of the same specification is reduced from 5 hours and 20 minutes to 2 hours and 30 minutes for one bending production compared with the ordinary heating kiln. Prepare 1m 2 The unit energy consumption of the hot-bending sheet is reduced from 4.8kw*h to 1.65kw*h. Reduce energy consumption up to 66%...

Embodiment 2

[0025] 2. Hot-bent glass-ceramic crystallization plate

[0026] Place a glass crystallization plate with a specification of 1050mm*1050mm*8mm on a curved body with a diameter of 800mm for hot bending; control the microwave output power to heat the plate to 820°C after 15 minutes, and then keep the plate temperature at 815°C ~825℃, last for 40min, and carry out hot bending. After the hot bending is completed, the plate is cooled to 630°C after 10 minutes, kept for 5 minutes, and cooled to room temperature after 80 minutes to obtain a glass-ceramic hot bent plate.

[0027] According to the statistics of the process, the production time of the microwave bending kiln of the same specification is reduced from 5 hours and 20 minutes to 2 hours and 30 minutes for one bending production compared with the ordinary heating kiln. Prepare 1m 2 The unit energy consumption of the hot-bending sheet is reduced from 5.6kw*h to 1.8kw*h. Reduce energy consumption up to 68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com