Microwave dryer for vegetable and fruit crops

A crop and dryer technology, applied in the fields of food science, application, food processing, etc., can solve the problems such as mildew and deterioration of fruit and vegetable kernels, affecting the quality of fruit and vegetable processing, and unstable product quality, and achieves less loss of nutrients and natural color. , the production environment is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

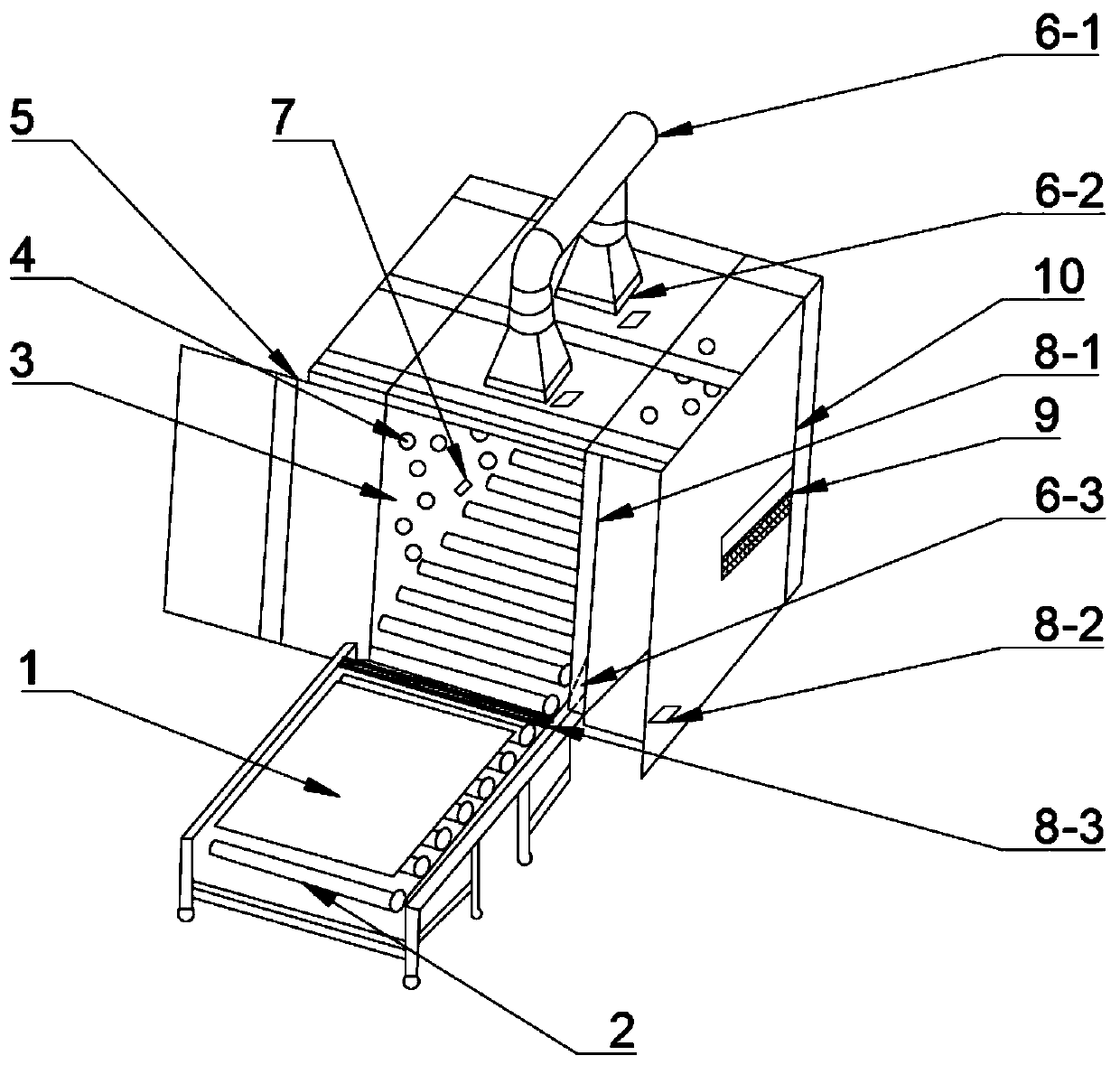

[0015] When the present invention is actually implemented, a microwave dryer for vegetables and fruits includes a tray 1, a roller table 2, a cavity 3, a magnetron 4, a door body 5, a moisture removal system 6, a temperature and humidity sensor 7, a shielding protection Layer 8, operation panel 9, control cabinet 10, the tray 1 is set on the roller table 2, and the lower end of the tray 1 is provided with some anti-skid patterns, and the cavity 3 is set at the bottom inside the fruit and vegetable microwave dryer , and a door body 5 is provided on one side of the cavity body 3, a pulley and a slide rail are arranged below the door body 5, and a plurality of magnetrons 4 are arranged on both sides of the cavity body 3, and the magnetron tubes 4 are rectangular. Array distribution, one end of the magnetron 4 is electrically connected to the control cabinet 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com