Absorption frequency adjustable microwave absorption material and preparation method thereof

A microwave absorbing material and absorbing frequency technology, applied in electrical components, antennas, magnetic field/electric field shielding, etc., can solve the problems of inability to effectively form a conductive network and reduce microwave absorbing performance, and achieve good microwave absorbing performance and absorbing frequency. The effect of adjusting and improving the microwave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

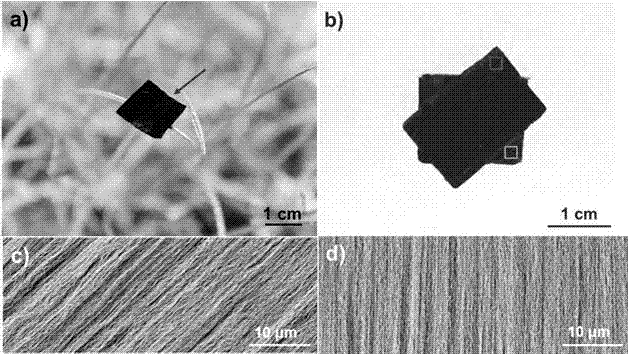

[0026] First, the preparation of aligned carbon nanotube films

[0027] Fe (thickness 1~2nm) / Al 2 o 3 (thickness of 10±2 nm) is the catalyst, ethylene is the carbon source, and the mixed gas of argon and hydrogen is the gas phase carrier, among which, Al 2 o 3 As a buffer layer, Fe is used as a catalyst, and a nanometer-thick film is deposited on a silicon wafer by an electron beam evaporation coating device; chemical vapor deposition is used, ethylene is used as a carbon source, and argon and hydrogen are used as a carrier gas. Synthesize vertically grown carbon nanotube arrays on Si substrates; the ethylene flow rate is 180-300 sccm, the argon flow rate is 390-650 sccm, and the hydrogen flow rate is 20-50 sccm, grown in a tube furnace for 10-180 min, namely A vertically grown carbon nanotube array is obtained. The details of synthesis and self-assembly can refer to existing literature reports. Use a polytetrafluoroethylene roller with a smooth surface to roll the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com