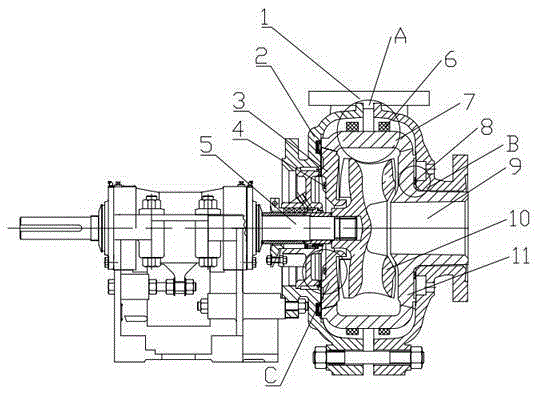

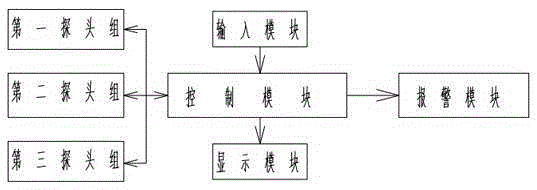

Slurry pump with alarm function for excessive wear of wetted parts

A technology of excessive wear and flow parts, which is applied in the direction of pump control, non-variable pumps, machines/engines, etc., can solve the problems of burning out drive motors, detection of parts that cannot pass current, and impellers that are easy to get stuck, so as to ensure The effect of safe production and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

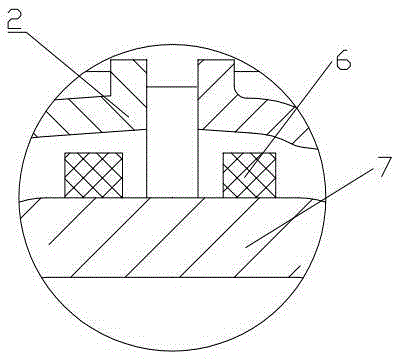

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Existing slurry pumps have many classifications according to the conveying medium and their own structure, but the structure is similar, and they are all suitable for conveying slurry medium. The general medium is not purely liquid medium, and may contain lumps and even be corrosive. Therefore, the slurry pump has higher requirements on the flow parts (in the present invention, only the front fender, the rear fender and the sheath are developed, and of course the blade thickness monitoring device can also be installed according to the demand). At present, wear-resistant materials are basically used. However, due to the fast running speed of the slurry pump, even if the flow parts of wear-resistant materials are used, there are periodic wears. If timely inspection, replacement or testing is not carried out, when the flow After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com