Liquid floating layer automatic recovery processing device

An automatic recovery and treatment device technology, applied in the direction of liquid separation, liquid separation auxiliary equipment, separation methods, etc., can solve the problems of oily wastewater entering, oily wastewater being discharged outside the station, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

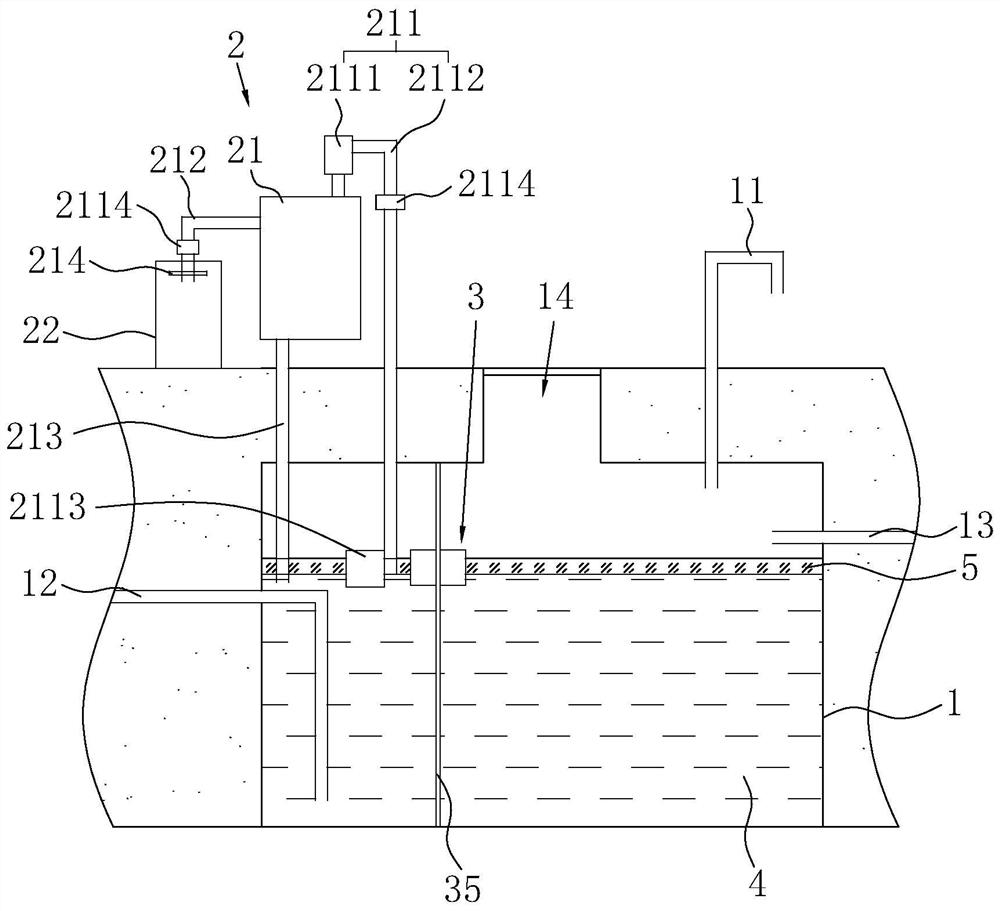

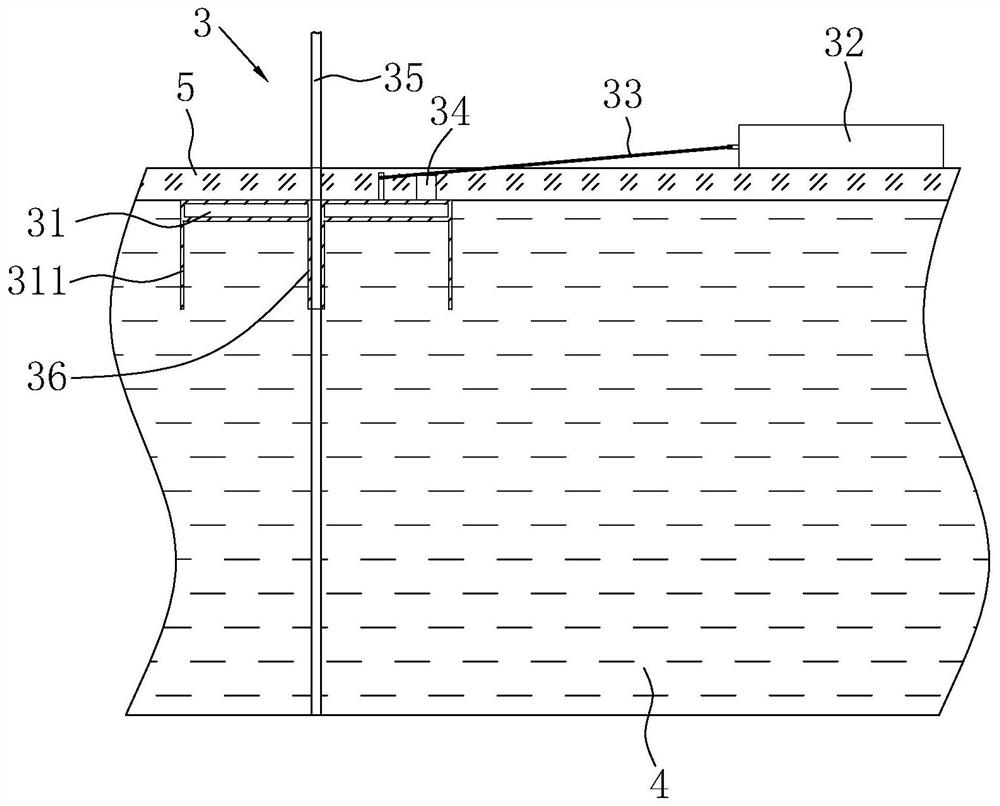

[0032] The technical solutions in the present invention will be further described below with reference to the accompanying drawings and embodiments.

[0033] A liquid floating layer automatic recovery and treatment device, refer to figure 1 , including the recovery tank 1 for receiving mixed liquids with different densities and incompatible, and the separation and recovery mechanism 2 for extracting and separating the base layer liquid 4 and the floating layer liquid 5. Using the separation and recovery mechanism 2, the recovery tank 1 can be recovered in time. The floating layer liquid 5 is separated out, and the pollution to the environment caused by the outflow of the floating layer liquid 5 in the recovery tank 1 is reduced.

[0034] refer to figure 1 , the recovery tank 1 is an internal hollow component. The recovery tank 1 can be made of impermeable concrete. The top of the recovery tank 1 is provided with an inspection well 14 for convenient maintenance, and a side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com