Plastic woven bag winding storage device

A plastic woven bag and storage device technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve problems such as jamming, loose material, and easy loosening of woven bags, so as to avoid loosening and ensure tension The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Combine below Attached picture The technical solution of the present invention will be further described through specific examples.

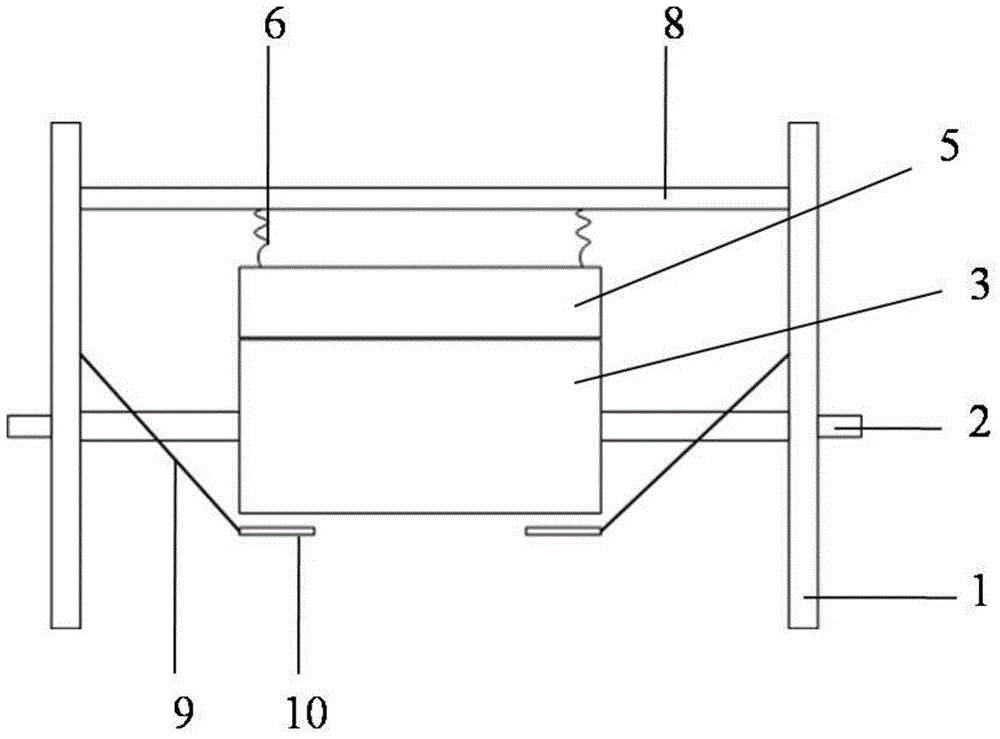

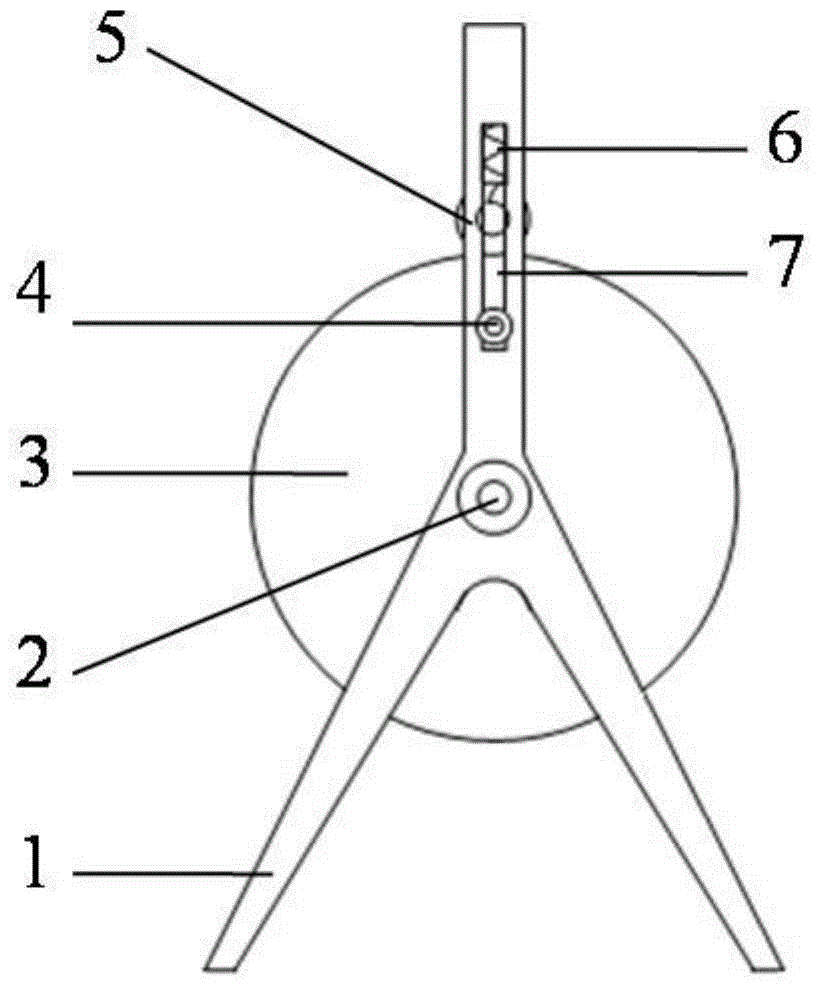

[0013] A winding storage device for plastic woven bags, comprising: a bracket 1, a roller shaft 2, a roller 3, a bolt 4, a pressure roller 5, a spring 6, a beam 8, a support rod 9, and a thickness detector 10; Groove 7, roller shaft 2 and crossbeam 8 are respectively erected on bracket 1, and roller shaft 2 and crossbeam 8 are parallel to each other; roller 3 is nested on roller shaft 2, pressure roller 5 is fixed on crossbeam 8 by spring 6, And the pressure roller 5 is tangent to the roller 3; one end of the support rod 9 is installed in the chute 7 on the support 1, and the support rod 9 is fixed on the support 1 by the bolt 4, and the other end of the support rod 9 is connected to the thickness detector 10. connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com