Preparation method of coaxial cable structure MWCNT/Fe3O4/ZnO/PANI microwave absorbant

A microwave absorbent, coaxial cable technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as insufficient binding force and poor wave absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

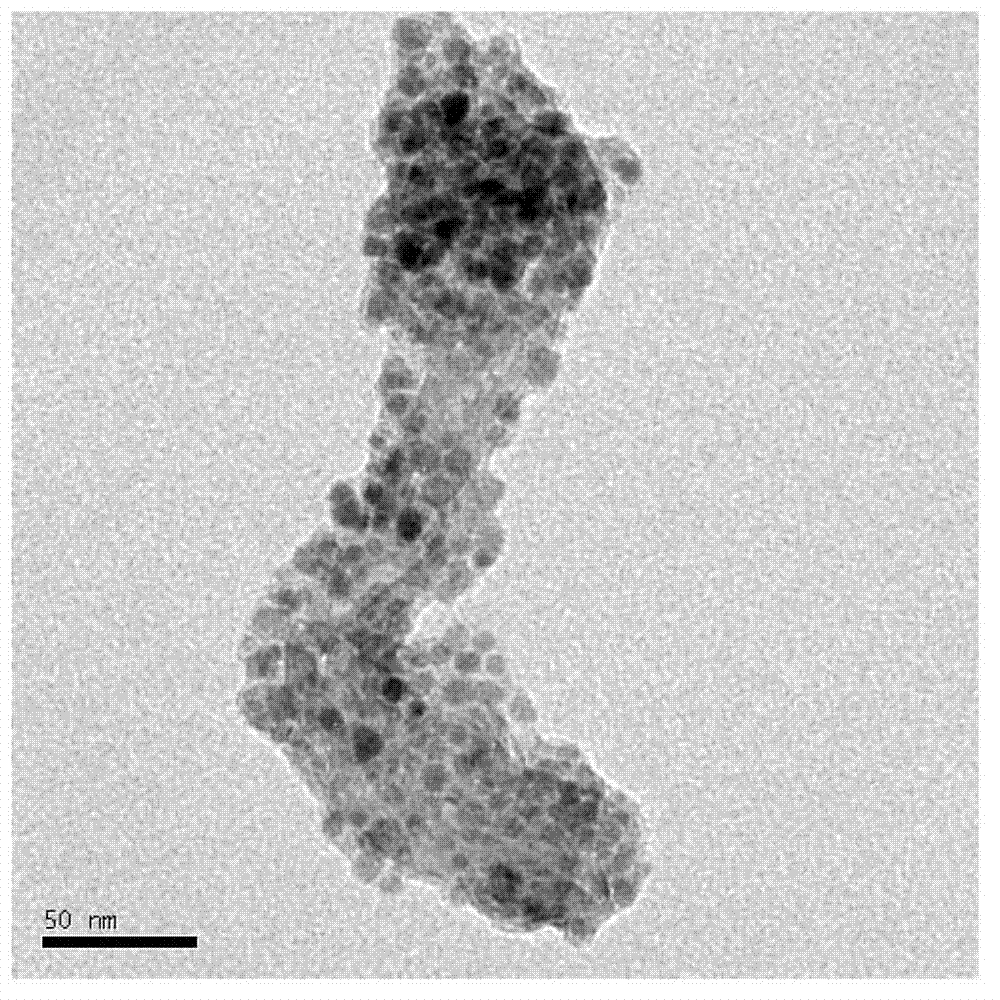

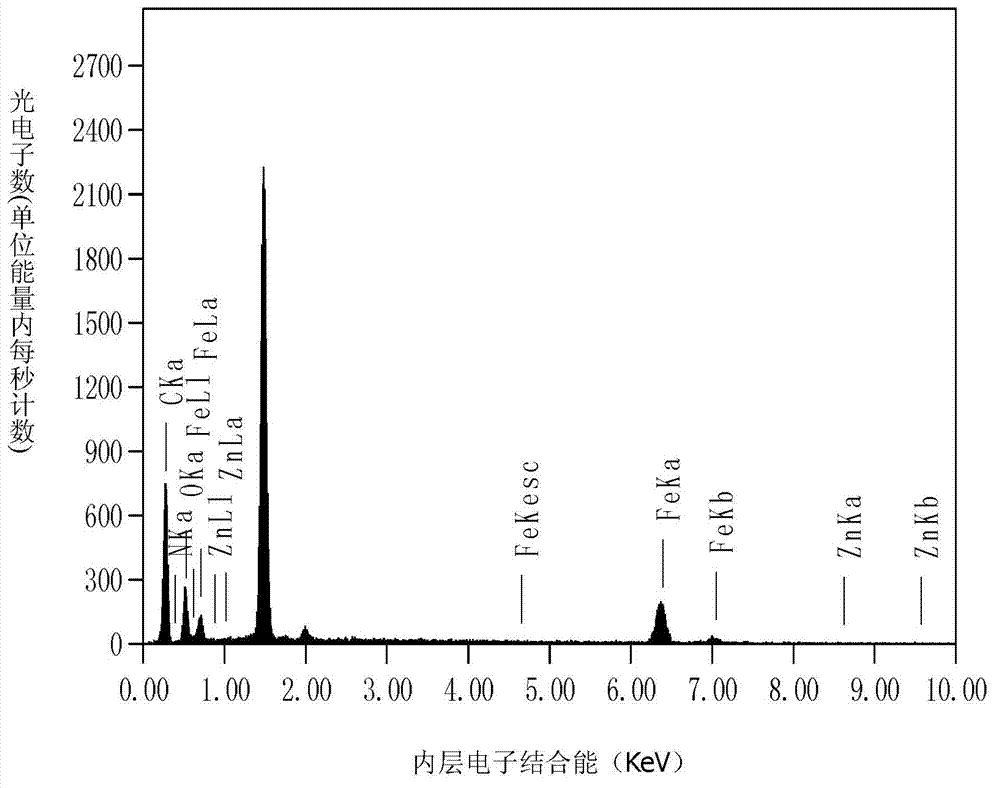

[0013] Specific implementation mode 1: In this implementation mode, a coaxial cable structure MWCNT / Fe 3 o 4 The preparation method of / ZnO / PANI microwave absorber, carries out as follows: one, carry out ultrasonic dispersion to multi-walled carbon nanotube, acetylacetonate iron and triethylene glycol respectively, then mix; Then under nitrogen as protective atmosphere condition, be heated to After boiling and reacting for 20-60 minutes, conduct magnetic separation, collect the solid phase, and then dry to obtain MWCNT / Fe 3 o 4 Nanomaterials; wherein the mass ratio of multi-walled carbon nanotubes to iron acetylacetonate is 1: (2-8), and the mass-volume ratio of multi-walled carbon nanotubes to triethylene glycol is 1 mg: (0.1 mL to 1 mL);

[0014] Two, the MWCNT / Fe that step 2 obtains respectively 3 o 4 Nanomaterials, zinc acetate and triethylene glycol are ultrasonically dispersed, then mixed, and then heated to boiling under nitrogen as a protective atmosphere. After 20...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the multi-walled carbon nanotubes in step 1 have a diameter of 30-60 nm and a length of 5-25 μm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the MWCNT / Fe obtained in step one 3 o 4 Fe in nanomaterials 3 o 4 The thickness of the layer is 2 to 8 nm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com