Preparation method and application of boron nitride/graphene/polyimide composite wave-absorbing and heat-conducting material

A technology of ene polyimide and heat-conducting materials, which is applied in the field of preparation of boron nitride-graphene polyimide composite wave-absorbing heat-conducting materials, can solve problems such as low efficiency, energy waste, and heat loss, and achieve cost reduction and temperature rise The effect is obvious and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of boron nitride graphene polyimide composite wave-absorbing heat-conducting material of the present invention comprises the following steps:

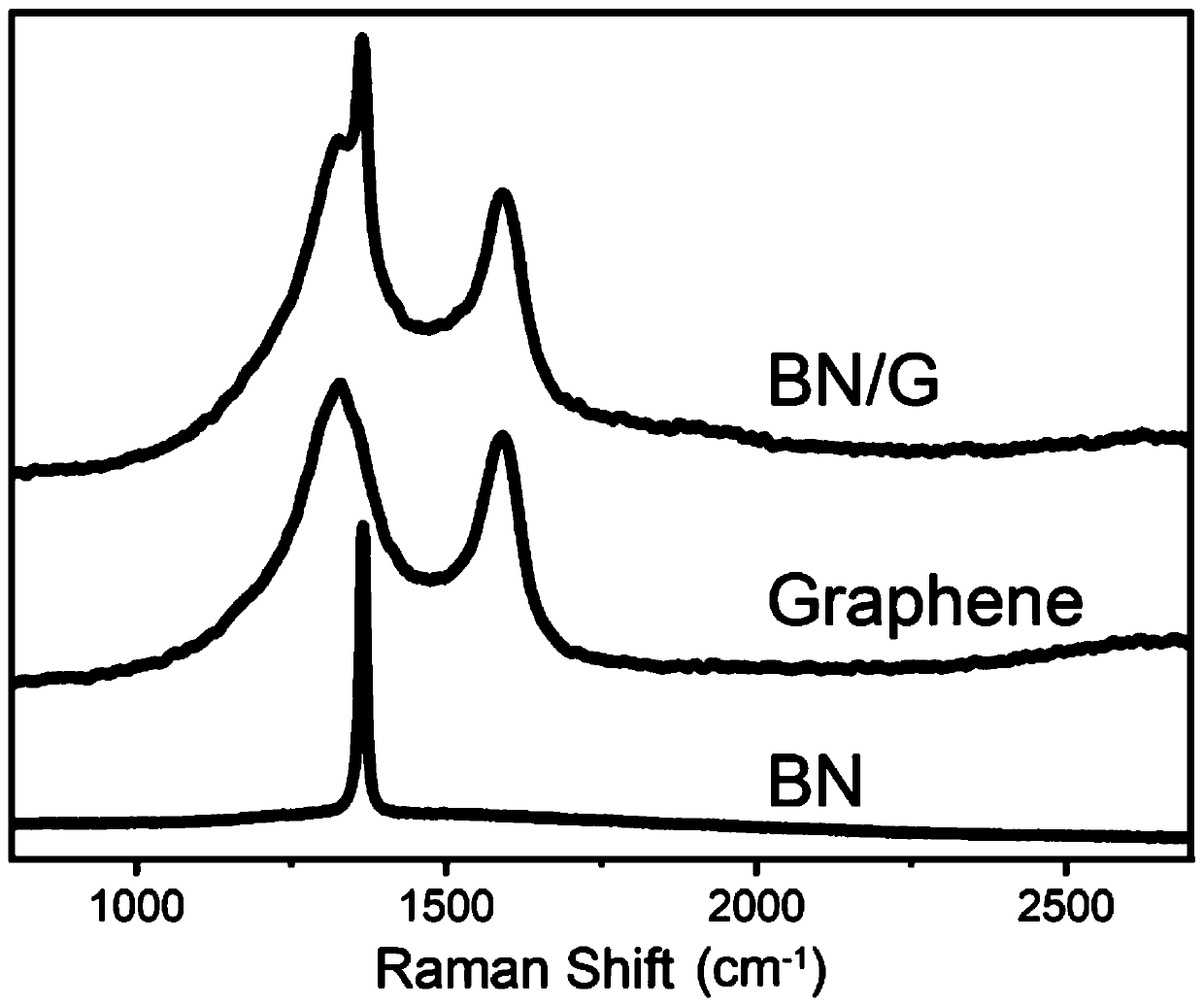

[0036] S1. Weigh and mix boron nitride powder and graphene powder. The mass ratio of boron nitride and graphene is 1: (0.01-0.02). Add absolute ethanol and put it into a ball mill tank for ball milling. Add to four-fifths of the ball mill tank, set the speed at 300-500rad / min, and the time is 1.5-2.5h;

[0037] Graphene includes at least one of expanded graphite, thermally exfoliated graphene, mechanically exfoliated graphene, liquid phase exfoliated graphene, high temperature carbonized graphene, 3D graphene, graphene oxide, reduced graphene oxide and CVD graphene.

[0038] S2. To prepare the precursor of the polyimide material, add the diamine into the polar solvent, stir it evenly and then add the dibasic anhydride. The molar ratio of the dibasic amine to the dibasic anhydride is 1:1, and the mass fractio...

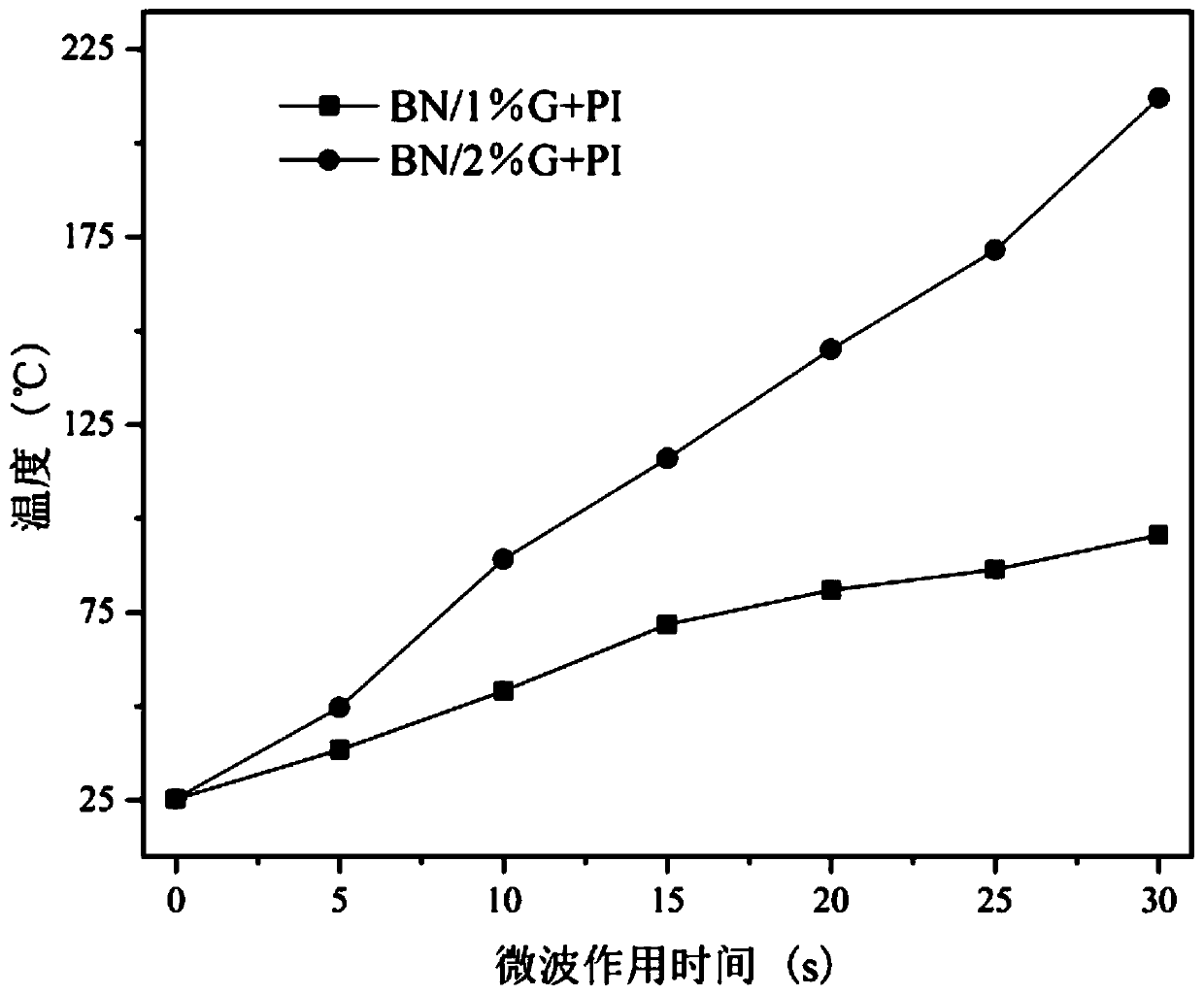

Embodiment 1

[0050](1) Weigh 5g of boron nitride powder and 0.05g of graphene powder, mix them in a beaker, add 50ml of absolute ethanol, put them into a ball mill jar for ball milling, set the speed at 300rad / min, and the time is 2.5h.

[0051] (2) To prepare the precursor of polyimide material, weigh 1.013g of 4,4'-diaminodiphenyl ether, add it to 12g of N,N-dimethylacetamide, magnetically stir for 2h, then add 1.104g of Phenylenetetracarboxylic dianhydride, stirred by magnetic force for 10h.

[0052] (3) Put the solution prepared in step (1) into a blast oven to dry for 10 hours to obtain a boron nitride / graphene composite powder, press a hydraulic press for tableting, a mold with a diameter of 16mm, and a pressure of 6Mpa for 10min, take it out and add it dropwise (2) The polyimide precursor solution prepared in (2) until the entire sheet is infiltrated.

[0053] (4) Put the composite material into the horse boiling furnace, set the initial temperature to 25°C, raise the temperature t...

Embodiment 2

[0056] (1) Weigh 5g of boron nitride powder and 0.1g of graphene powder, mix them in a beaker, add 50ml of absolute ethanol, put them into a ball mill jar for ball milling, set the speed at 500rad / min, and the time is 1.5h.

[0057] (2) To prepare the precursor of polyimide material, weigh 1.013g of 4,4'-diaminodiphenyl ether, add it to 12g of N,N-dimethylacetamide, magnetically stir for 2h, then add 1.104g of Phenylenetetracarboxylic dianhydride, stirred by magnetic force for 10h.

[0058] (3) Put the solution prepared in step (1) into a blast oven and dry for 10 hours to obtain a boron nitride / graphene composite powder, press a hydraulic press for tableting, a mold with a diameter of 16mm, and a pressure of 10Mpa for 10 minutes, take it out and add it dropwise (2) The polyimide precursor solution prepared in (2) until the entire sheet is infiltrated.

[0059] (4) Put the composite material into the horse boiling furnace, set the initial temperature at 25°C, raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com