Bimetallic cobalt-based core-shell material as well as preparation method and application thereof

A metal cobalt-based, core-shell technology, applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of high temperature energy consumption, complicated and multi-step, harsh conditions, etc., to achieve low preparation cost and broad application prospects , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 0.7137g CoCl 2 ·6H 2Dissolve O (0.05M) and 0.8g PVP in 60mL of pure ethylene glycol, stir magnetically for 2h to fully dissolve to obtain a lavender solution; then slowly add 1.76mL of 85% hydrazine hydrate dropwise and continue stirring for 1h. The resulting solution was added to a polytetrafluoroethylene lining and a powerful magnet (0.12T) was added under the lining, sealed in a stainless steel kettle, and kept at 160°C for 4h. Finally, the obtained gray-black precipitate was separated by magnetic separation, washed several times with absolute ethanol, and vacuum-dried at 40° C. to obtain the product, which was a fibrous cobalt material.

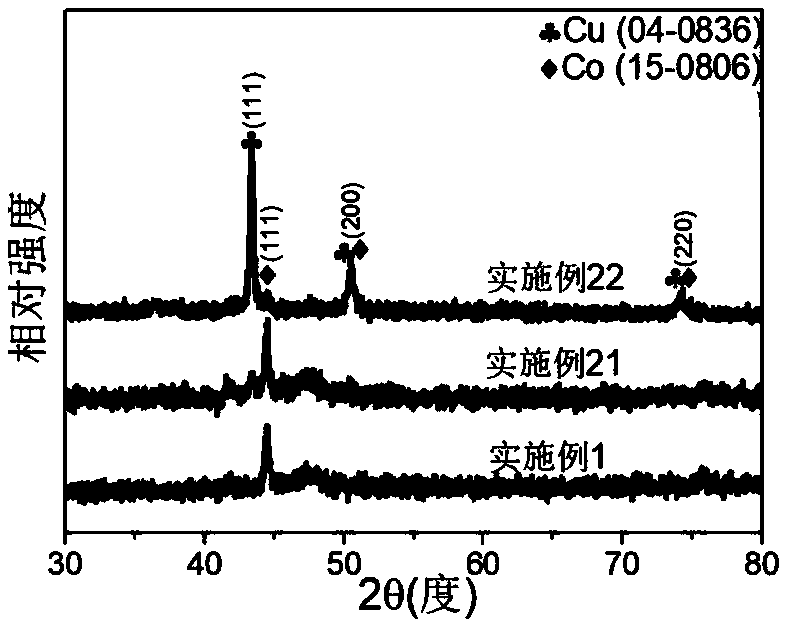

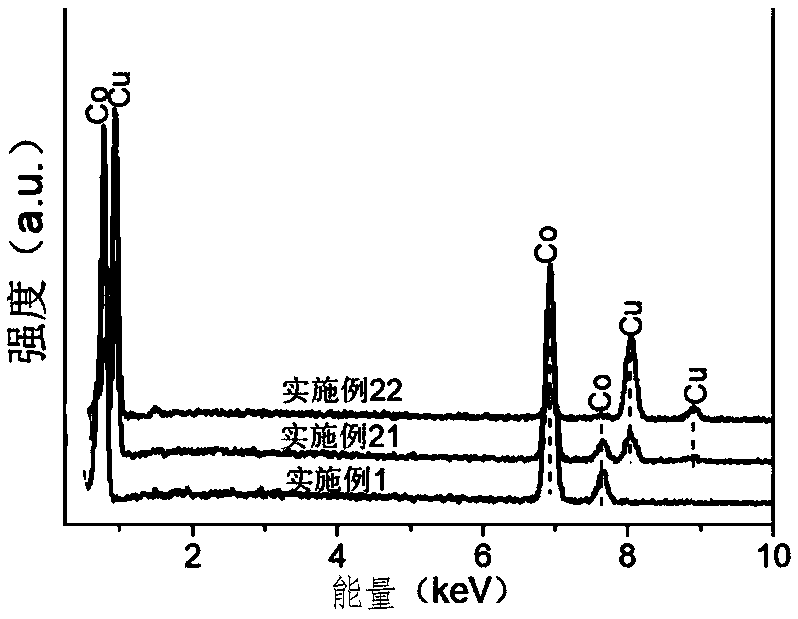

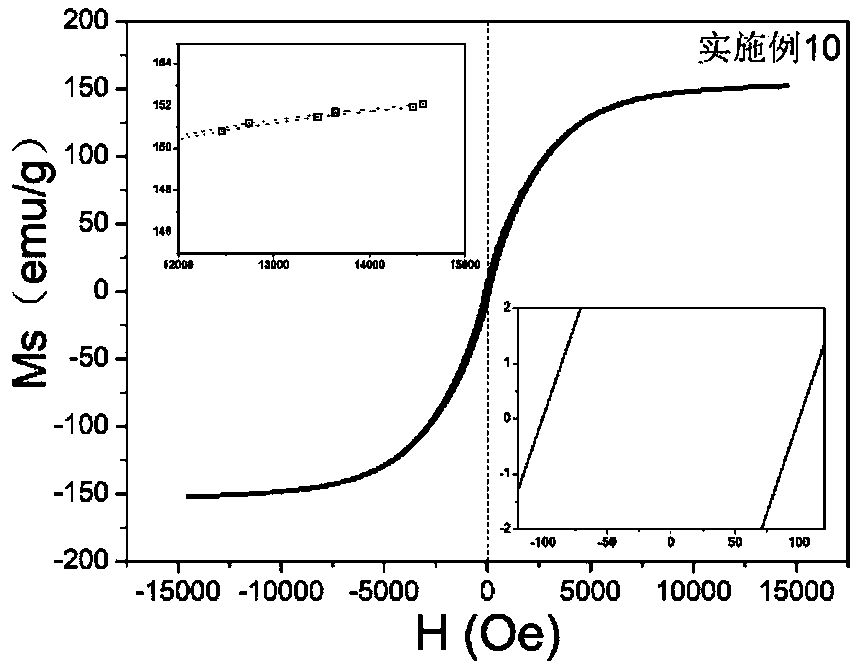

[0040] The resulting product is a gray-black fibrous solid, and its phase, the morphology observed under a scanning electron microscope, and the phase are as follows: Figure 1~3 As shown, it can be seen that the product is a fibrous structure with a size of 7-15 μm. Its energy spectrum is as Figure 4 As shown, its static magn...

Embodiment 2

[0042] The steps are the same as in Example 1, but the hydrothermal reaction temperature is 200°C. The resulting product is a gray-black fiber, and the morphology observed under a scanning electron microscope is as follows: Figure 7 As shown, the fiber diameter is 7-13 μm.

Embodiment 3

[0044] Same as Example 1 step, but add 0.3569g CoCl 2 ·6H 2 O (0.025M) and 0.88 mL volume fraction of 85% hydrazine hydrate. The resulting product is a gray-black fiber, and its morphology observed under a scanning electron microscope is as follows: Figure 8 As shown, the fiber diameter is 3-7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com