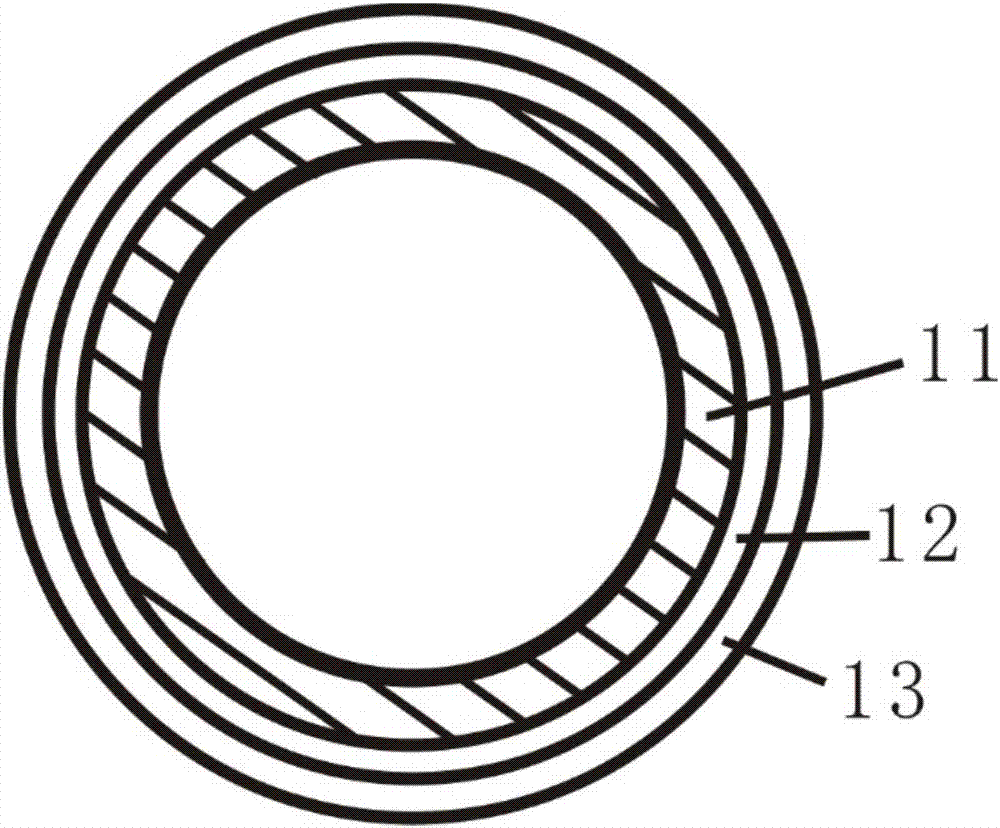

Multilayer hollow composite wave-absorbing material

A composite wave-absorbing material and hollow structure technology, applied in the field of wave-absorbing materials, can solve problems such as poor absorption of low-frequency microwaves and high density of ferrite, and achieve increased dielectric constant, increased magnetic permeability, and increased absorbing loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1, prepare hollow nickel

[0046] a) carbonyl iron powder pretreatment

[0047] Ultrasonically treat carbonyl iron powder with a particle size of about 5 μm in acetone for 50 minutes to remove impurities on its surface, then soak it in 1mol / L dilute hydrochloric acid for 20 seconds to remove the oxide film on its surface, and put it away after treatment Dry in a vacuum oven;

[0048] b) Configure the plating solution

[0049] Mix 0.1mol / L nickel sulfate solution and 40g / L sodium tartrate solution, after fully stirring, add 0.8g / L thiourea solution and continue stirring to allow thiourea to fully dissolve, then add 55g / L hydrazine hydrate solution, fully Stir evenly to obtain a turbid solution, add 1mol / L sodium hydroxide solution to the turbid solution to adjust the pH to 11 while stirring, so that the turbid solution becomes a solution without precipitation, which is the nickel plating solution;

[0050] c) Nickel plating

[0051] Put the prepared plating solu...

Embodiment 2

[0065] Step 1, prepare hollow nickel

[0066] a) carbonyl iron powder pretreatment

[0067] Ultrasonically treat carbonyl iron powder with a particle size of about 5 μm in acetone for 50 minutes to remove impurities on its surface, then soak it in 1mol / L dilute hydrochloric acid for 20 seconds to remove the oxide film on its surface, and put it away after treatment Dry in a vacuum oven;

[0068] b) Configure the plating solution

[0069] Mix 0.1mol / L nickel sulfate solution and 40g / L sodium tartrate solution, after fully stirring, add 0.8g / L thiourea solution and continue stirring to allow thiourea to fully dissolve, then add 55g / L hydrazine hydrate solution, fully Stir evenly to obtain a turbid solution, add 1mol / L sodium hydroxide solution to the turbid solution to adjust the pH to 11 while stirring, so that the turbid solution becomes a solution without precipitation, which is the nickel plating solution;

[0070] c) Nickel plating

[0071] Put the prepared plating solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com