Solid acid catalyst suitable for microwave-assisted reaction and preparation method of solid acid catalyst

A solid acid catalyst, microwave-assisted technology, used in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unfavorable separation, inconvenient storage and sales, and achieve good reusability. Good performance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

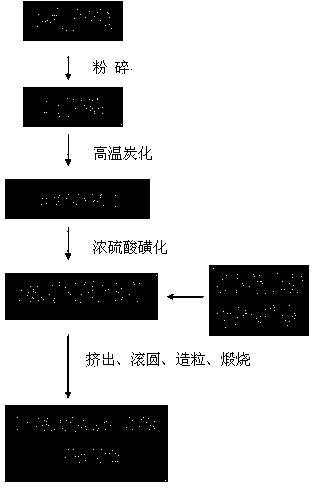

[0028] After the corn was dedusted and impurity removed, it was crushed through an 80-mesh sieve, dried at a constant temperature of 50°C for 4 hours, and then carbonized in a muffle furnace at 400°C for 2 hours to obtain an activated carbon carrier. The activated carbon carrier after carbonization was impregnated with concentrated sulfuric acid in a stirred environment for sulfonation reaction. The mass ratio of activated carbon to concentrated sulfuric acid was 1g:10ml, and the sulfonation reaction was stirred at a constant temperature of 90°C for 1h at a low speed, and the stirring rate was 300rpm.

[0029] After the reaction, wash with distilled water until neutral, mix the sulfonated product with iron filings powder, zeolite and appropriate amount of dextrin evenly, the weight ratio is 1:0.1:0.2:0.08, and granulate by extrusion spheronization, extruder The rotation speed is 130 rpm, the diameter of the extrusion template hole is 1 mm, and the diameter distribution of 90% o...

Embodiment 2

[0033] After the black beans were dedusted and impurity removed, they were crushed through an 80-mesh sieve, dried at a constant temperature of 60°C for 3 hours, and then carbonized in a muffle furnace at 500°C for 1 hour to obtain an activated carbon carrier. The carbonized activated carbon carrier is impregnated with concentrated sulfuric acid in a stirring environment for sulfonation reaction. The mass ratio of solid particles to concentrated sulfuric acid is 1g:15ml. Stir the sulfonation reaction at a constant temperature of 70°C for 3 hours at a low speed, and the stirring rate is 100rpm .

[0034] After the reaction was finished, wash with distilled water until neutral, and the sulfonated product was mixed with Fe 2 o 3Powder, zeolite and appropriate amount of sodium carboxymethyl cellulose are mixed evenly, the weight ratio is 1: 0.05: 0.15: 0.1, the method of extrusion spheronization is used to granulate, the speed of the extruder is 130 rpm, and the diameter of the e...

Embodiment 3

[0037] After the soybeans were dedusted and impurity removed, they were crushed through an 80-mesh sieve, dried at a constant temperature of 80°C for 1 hour, and then carbonized in a muffle furnace at 250°C for 3.5 hours to obtain an activated carbon carrier. The carbonized activated carbon carrier is impregnated with concentrated sulfuric acid in a stirring environment for sulfonation reaction. The mass ratio of solid particles to concentrated sulfuric acid is 1g:8ml. Stir the sulfonation reaction at a constant temperature of 120°C for 1 hour at a low speed, and the stirring rate is 100rpm .

[0038] After the reaction, wash with distilled water until neutral, mix the sulfonated product with alumina powder, zeolite and appropriate amount of starch evenly, the weight ratio is 1:0.08:0.12:0.05, and granulate by extrusion spheronization, the extruder speed 130 rpm, the diameter of the extrusion template hole is 1.2mm, and the diameter of 90% of the spherical particles after sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com