Organogel blocking agent for water blocking and profile control, and preparation method and application thereof

An organogel, water plugging and profile control technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as inability to meet profile control requirements, low construction success rate, and high biological toxicity of phenolic oligomers , to achieve the effects of improving development benefit and recovery rate, increasing benefit and recovery rate, and good adjustable gelling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

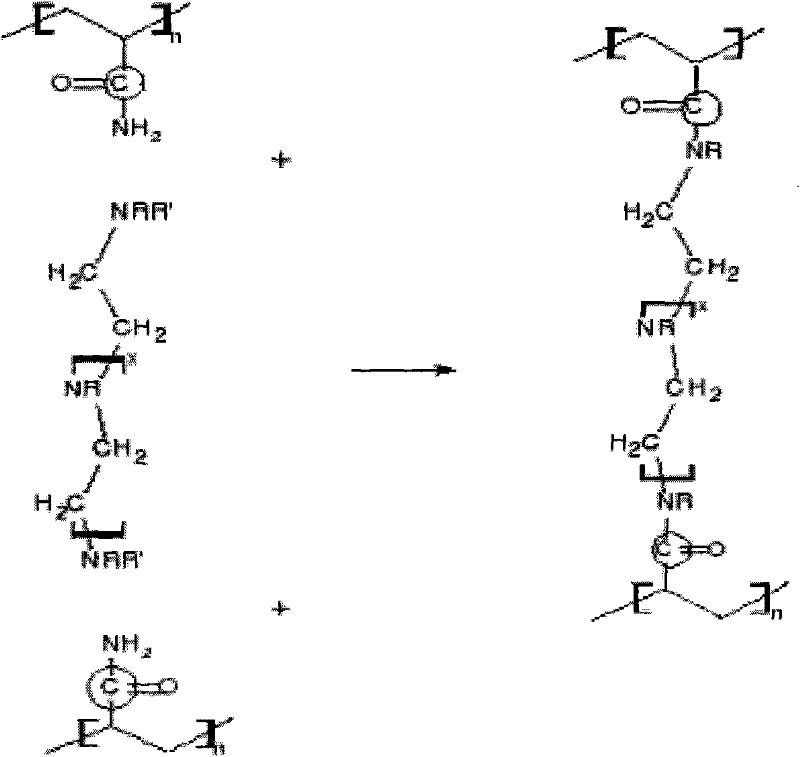

Method used

Image

Examples

Embodiment 1

[0032] (1) Chemical modification of polymer crosslinking agent: take 40g polyethyleneimine (PEI, M=3.0×10 3 , 30% aqueous solution) was placed in a reaction flask with a condenser, thermometer, stirring bar and addition funnel. While stirring, put 10mL of anhydrous acetic acid into the addition funnel and slowly add it into the reaction flask. After the addition of anhydrous acetic acid is completed, stir the reactant at 60°C to 70°C for 3 hours, cool to room temperature, take it out, and use 50% sodium hydroxide solution to adjust the pH of the solution to 7.0. Adjust the concentration of PEI in the product to 12% with water to obtain polymer modified cross-linking agent PEI-A 1#.

[0033] (2) Preparation of polymer organogel plugging agent solution: take 1.25g polyacrylamide (M=8.0×10 6 , degree of hydrolysis 3%) add 90g of water, stir for 4 hours until the polyacrylamide is completely dissolved, then add 2.5g of the polymer modified cross-linking agent PEI-A 1#, 0.25g of ...

Embodiment 2

[0047] (1) Chemical modification of polymer crosslinking agent: take 40g polyethyleneimine (PEI, M=1.5×10 4 , 35% aqueous solution) was placed in a reaction flask with a condenser, thermometer, stirring bar and addition funnel. While stirring, put 10mL of anhydrous acetic acid into the addition funnel and slowly add it into the reaction flask. After the addition of anhydrous acetic acid is completed, stir the reactant at 60°C to 70°C for 3 hours, cool to room temperature, take it out, and use 50% sodium hydroxide solution to adjust the pH of the solution to 7.0. Adjust the concentration of PEI in the product to 12% with water to obtain the polymer modified cross-linking agent PEI-A 2#.

[0048] (2) Polymer organogel plugging agent solution preparation: get 0.6g acrylamide / tert-butyl acrylate copolymer (containing 95% acrylamide and 5% tert-butyl acrylate in the copolymer, M=6.0×10 6 , degree of hydrolysis 3%), add 90g water, stir for 4 hours until the polyacrylamide is compl...

Embodiment 3

[0057] (1) Preparation of polymer organogel plugging agent solution: take 0.2g polyacrylamide (M=1.2×10 7 , degree of hydrolysis 10%), add 90g of water, stir for 4 hours until the polyacrylamide is completely dissolved, then add 0.4g of polymer modified cross-linking agent PEI-A 2#, 0.2g of sodium bicarbonate, make up the total mass of the solution to 100g with water, Stir well and set aside.

[0058] (3) Gelling time and thermal stability test:

[0059] After the polymer organogel plugging agent solution is prepared, put the solution into three vials, press the caps and seal them, put them in an oven at 90°C, observe and record the gelation time, take out a bottle after standing for 10 days, and open it to measure the gel viscosity. Elasticity, the remaining 2 bottles were placed in the oven for 90 days, and the "visual code evaluation method" commonly used in the petroleum industry was used to evaluate and record the change of gel strength within 90 days. The results are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com