Preparation method of alkali oxygen evolution reaction electrocatalyst

An oxygen evolution reaction, electrocatalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor stability, catalytic overpotential, etc., and achieve stable Good performance, increased specific surface area, strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The conductive substrate is nickel foam, the cobalt source is cobalt nitrate, and the reducing agent is sodium borohydride.

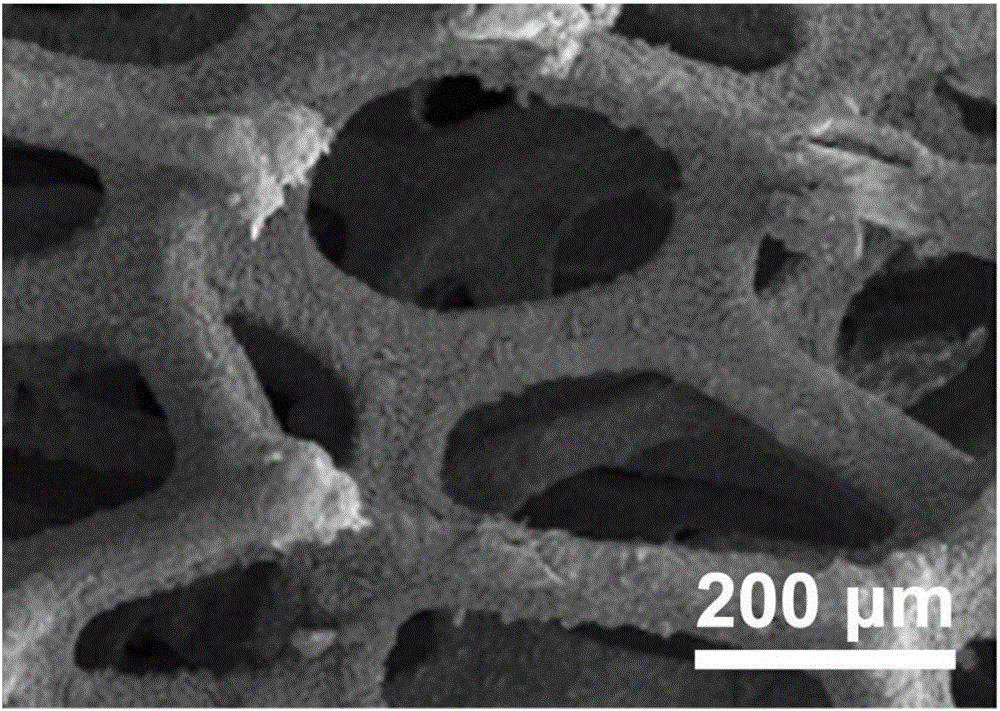

[0036] (1) Use nickel foam as a conductive substrate in 5 mol / liter hydrochloric acid for ultrasonic cleaning for 10 minutes, then transfer to an acetone solution for ultrasonic cleaning for 10 minutes, then transfer to an ethanol solution for ultrasonic cleaning for 10 minutes, and finally fully clean it with deionized water The conductive substrate was rinsed and placed in an oven at 60°C for drying.

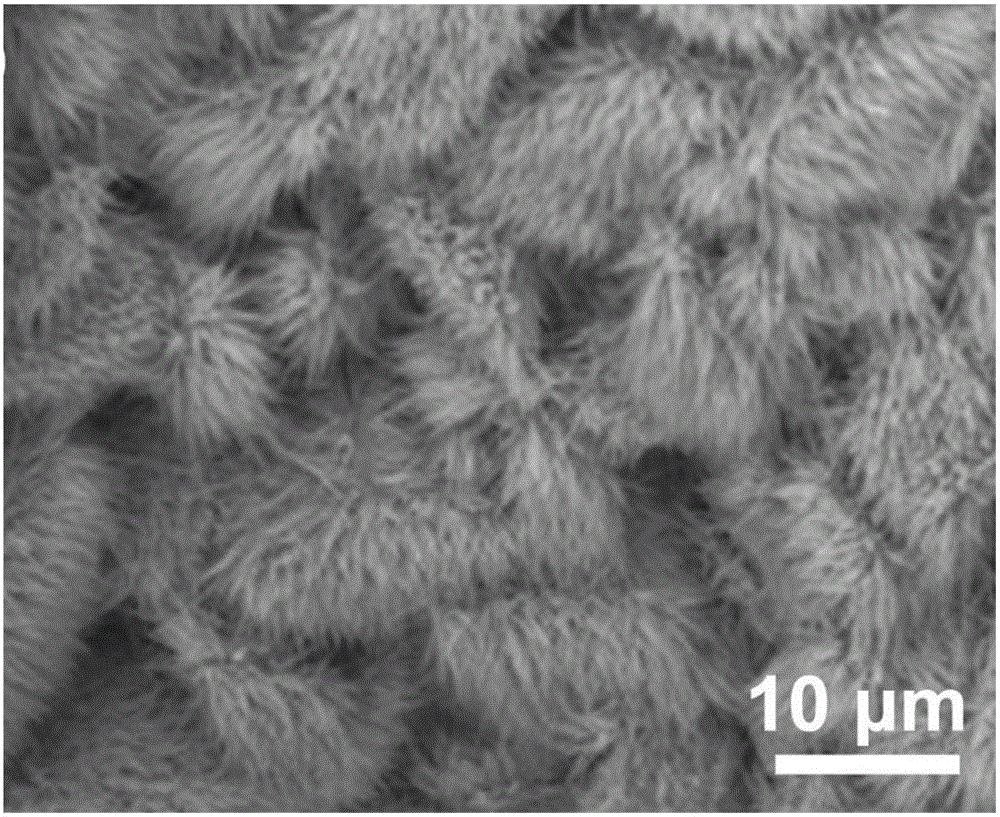

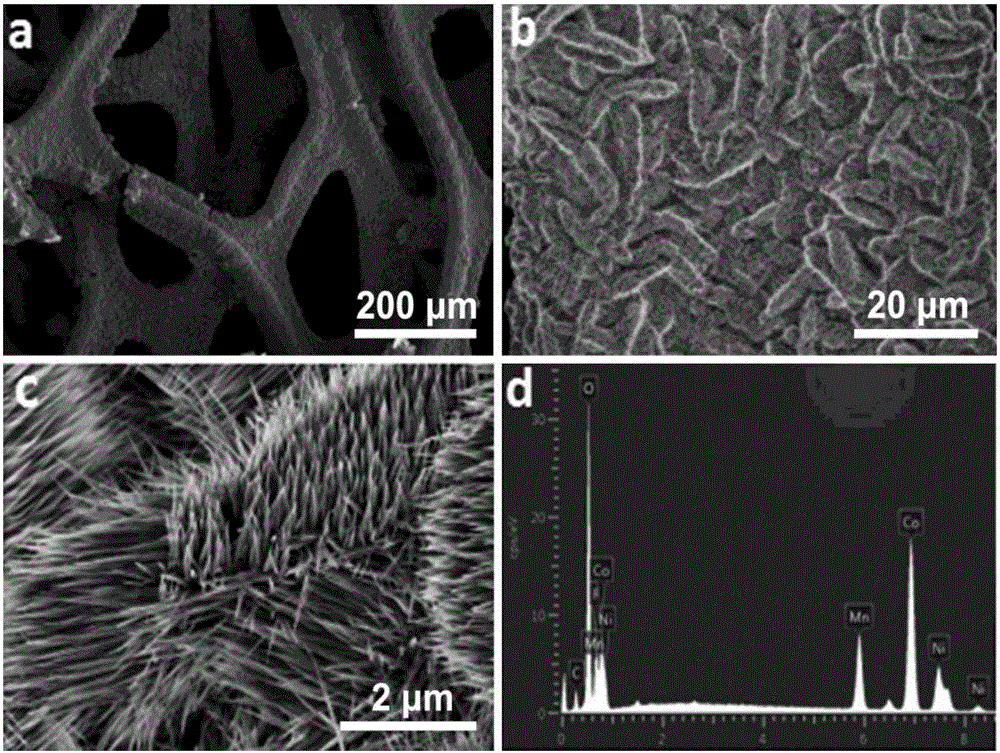

[0037] (2) Prepare a precursor solution, including 0.03516 mol / L cobalt nitrate, 0.01172 mol / L manganese nitrate, 0.2 mol / L ammonium fluoride, and 0.25 mol / L urea. The solution was magnetically stirred for 10 minutes and then transferred to the reactor, and then the foamed nickel treated in step (1) was put into the reactor obliquely, then the reactor was covered and tightened, and placed in a drying oven to heat up to 100°C. The time is set to ...

Embodiment 2

[0057] The preparation method of this electrocatalytic material is basically the same as that of Example 1, the difference is that the amount of sodium hydroxide and sodium borohydride in step (4) is different, respectively 3M and 0M, and the material is named NaOH@Mn x co 3-x o 4 -1:3. Embodiment 2 can achieve the object of the invention.

Embodiment 3

[0059] The preparation method of this electrocatalytic material is basically the same as that of Example 1, the difference being that the amount of sodium hydroxide and sodium borohydride in step (4) is different, respectively 0M and 1M. The material is named as NaBH 4 @Mn x co 3-x o 4 -1:3. Embodiment 3 can achieve the object of the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com