Lithium ion battery safe coating and preparation method thereof

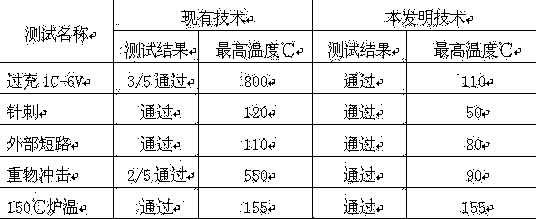

A lithium-ion battery, safe technology, applied in the direction of coating, electrode manufacturing, battery pack components, etc., can solve problems such as fire, battery heat out of control explosion, unable to solve large-area internal short circuit of the battery, etc., to reduce current and application costs Effect of low and internal resistance polarization increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The positive electrode used in the present invention includes positive electrode active material lithium nickel cobalt manganate 94% (weight ratio), conductive agent 2% (weight ratio), binder 4% (weight ratio); negative electrode includes negative electrode active material artificial graphite 96% ( weight ratio), conductive agent 2% (weight ratio), binder 2% (weight ratio); the separator uses three layers of PP / PE / PP separator with a thickness of 20μm.

[0029] The battery capacity is 5.2Ah, and the electrolyte lithium salt is LiPF 6 , concentration 1mol / L, electrolyte solvent is ethylene carbonate (EC): diethyl carbonate (DEC): ethyl methyl carbonate (EMC) = 1:1:1.

[0030] Mix aluminum oxide oxyhydroxide (AlOOH) 34.98% (weight ratio), NMP 65% (weight ratio), PVDF 0.02% (weight ratio), use a high-speed disperser or ball mill to mix evenly, and the viscosity is in the range of 100mPa.s-1500mPa.s Inside; use roller coating, gravure printing or spraying to coat the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com