Method for simulation test of influence of alkali metal on coke degradation

A simulation test, alkali metal technology, applied in color/spectral characteristic measurement, furnace, blast furnace details, etc., can solve problems such as inability to simulate test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Taking the adsorption test of coke to potassium vapor under high temperature as an example, its specific implementation method is:

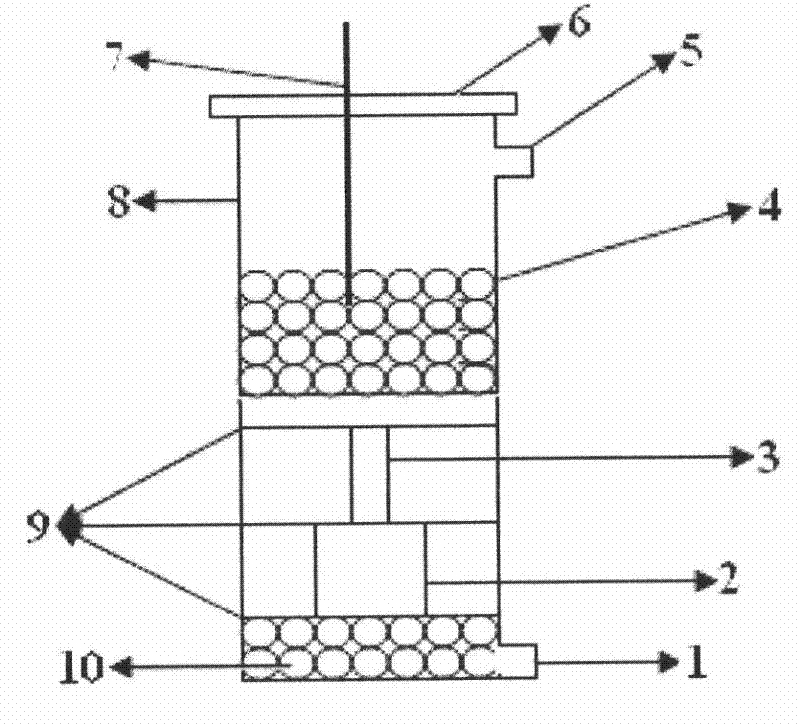

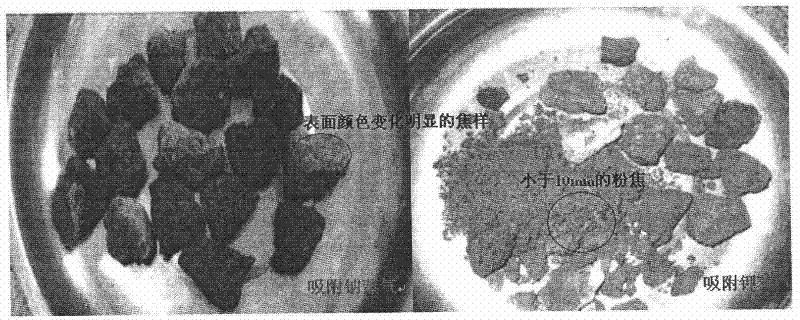

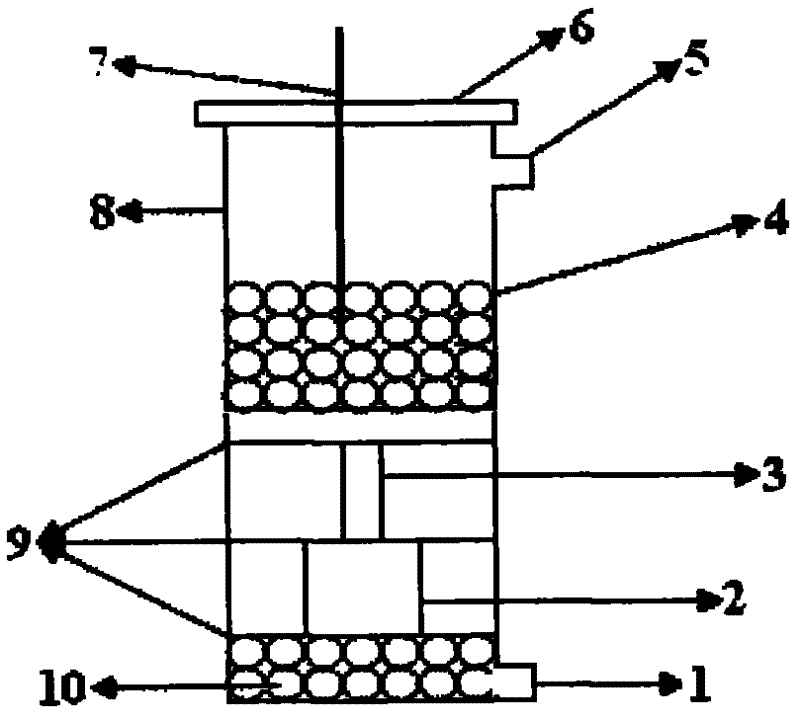

[0014] Take 200g of coke with a particle size of 21-25mm actually used in the blast furnace, and then according to the reaction: 2C+K 2 CO 3 =3CO+2K Get the required potassium carbonate 17.69g and excessive activated carbon powder 4.0g to produce 10g elemental potassium, put potassium carbonate and activated carbon powder into corundum crucible 2 after mixing, then corundum crucible 2 is put into the present invention In the reaction tube 8 of the reaction tube 8, a ventilative porous corundum gasket 9 is placed on the corundum crucible 2, and then 50 mm high corundum branch pipes 3 and 3 are placed, and a ventilative porous corundum gasket 9 is placed on the corundum branch pipe 3. 200g of coke, then seal the upper cover 6 of the reaction tube, start feeding 5 l / min of high-purity nitrogen to remove air, then cover the upper cover 6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com