High water-containing mud curing agent for mine filling and using method thereof

A mud solidifying agent and mine filling technology, which is used in filling materials, mining equipment, earth-moving drilling, etc., can solve problems such as difficulty in application, limited potential for later strength growth, unsatisfactory setting speed and early strength, etc. Good operability and cost-effectiveness, the effect of increasing early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

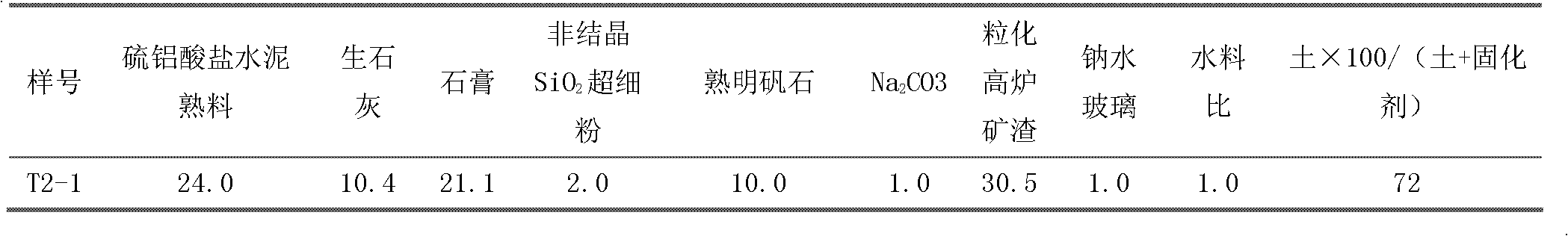

[0013] The present invention will be described in further detail below in conjunction with specific examples.

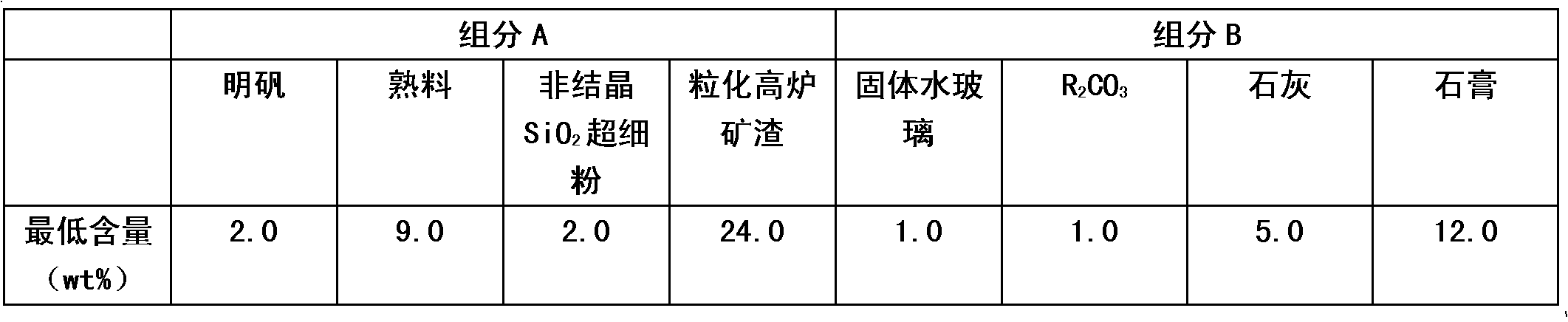

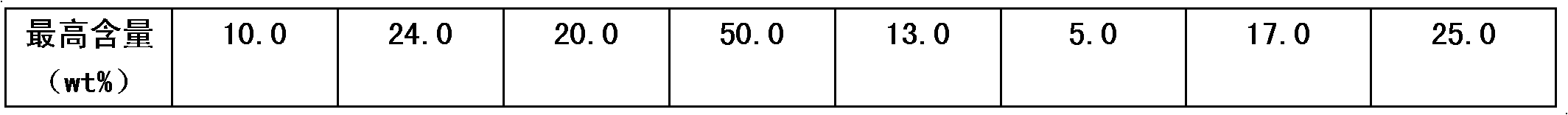

[0014] The main material of the high-water-content slurry curing agent for mine filling of the present invention is solid mixed powder, and the powder is composed of component A and component B. Wherein, component A is made of alum (potassium alum and / or boiled alunite), sulfoaluminate and / or ferric aluminate and / or high alumina cement clinker (hereinafter referred to as clinker), amorphous SiO 2 Ultrafine powder (BET specific surface area > 15000m 2 / Kg), granulated blast furnace slag; component B consists of lime (quicklime and / or slaked lime), gypsum (natural gypsum, construction gypsum, anhydrite and various industrial gypsum), modulus n=1.0~1.6 Solid water glass nSiO 2 · R 2 O, alkali metal carbonate R 2 CO 3 (R is an alkali metal) composition. The distribution ratio of each group is shown in Table 1.

[0015] Table 1 Mass percentage of curing agent ingre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com