Process for preparing nano rareearth oxidate powder

A technology of oxide powder and nano-rare earth, which is applied in the direction of dyeing physical treatment, can solve the problems of ammonia emission, environmental pollution, and cannot meet the requirements of good dispersion and uniformity, and achieve the effect of uniform particle size and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

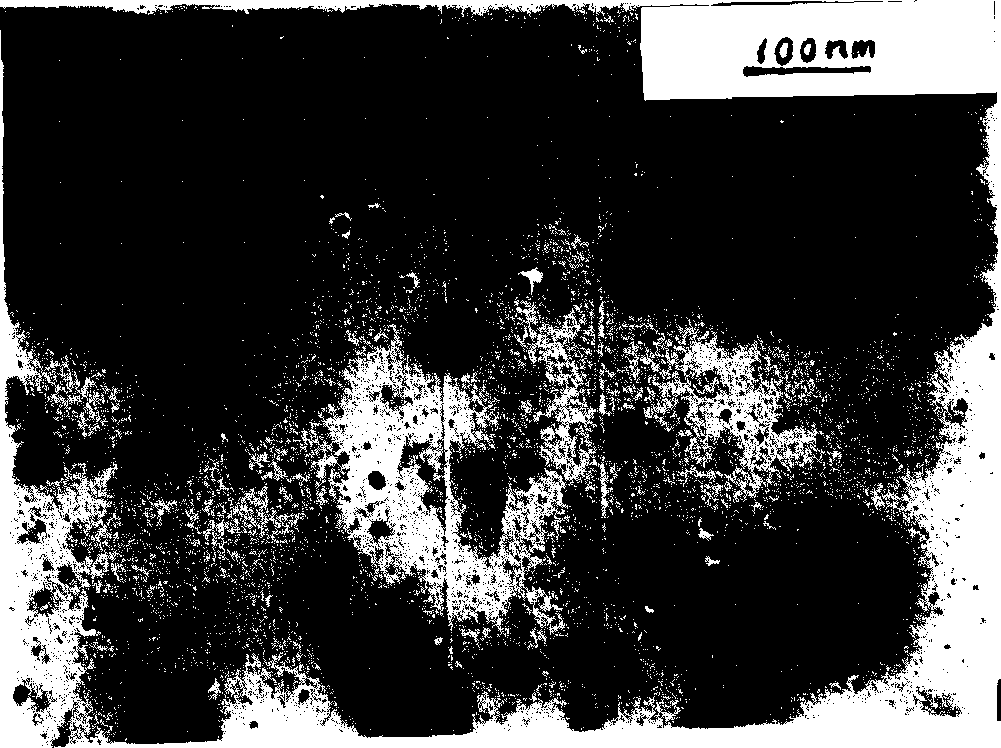

[0011] 1.5 liters of 0.45mol / L Na 2 CO 3 Gradually add 0.37mol / L YCl to the aqueous solution 3 In the aqueous solution, stir while adding, so that the pH value is 7; continuously stir for 10 minutes after the addition, and wash it with deionized water for 3 times after drying; add 20ml of absolute ethanol after drying, and stir evenly Then put it at 400°C for 1 hour, and after air cooling, nanometer Y with excellent dispersion and uniform particle size was obtained. 2 o 3 , with an average particle size of 10 nm, such as figure 1 shown.

Embodiment 2

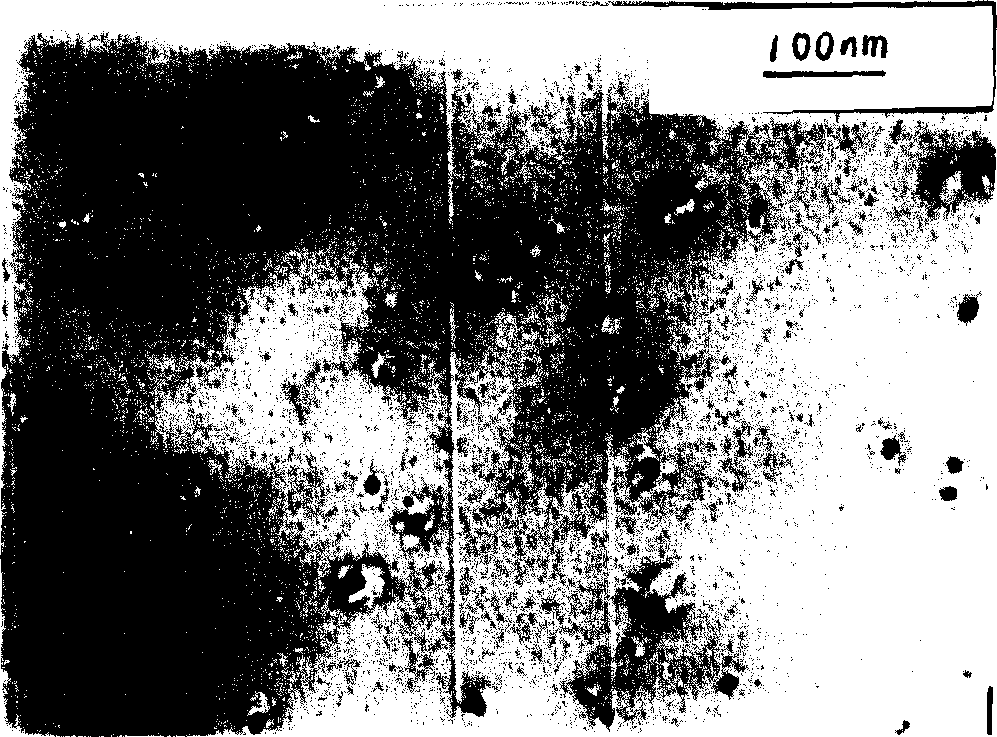

[0013] At 0.3mol / L Dy(NO 3 ) 3 Gradually pour 0.4mol / L NaOH aqueous solution into the aqueous solution, and stir while pouring, so that the pH value is 6; after stirring for 13 minutes, spin dry to obtain the precipitate Dy(OH) 3 , washed with distilled water and then added 20 ml of isopropanol; stirred evenly and burned at 600 ° C for 1.5 hours, and air-cooled to obtain nano Dy with an average particle size of 20 nm 2 o 3 ,Such as figure 2 shown.

Embodiment 3

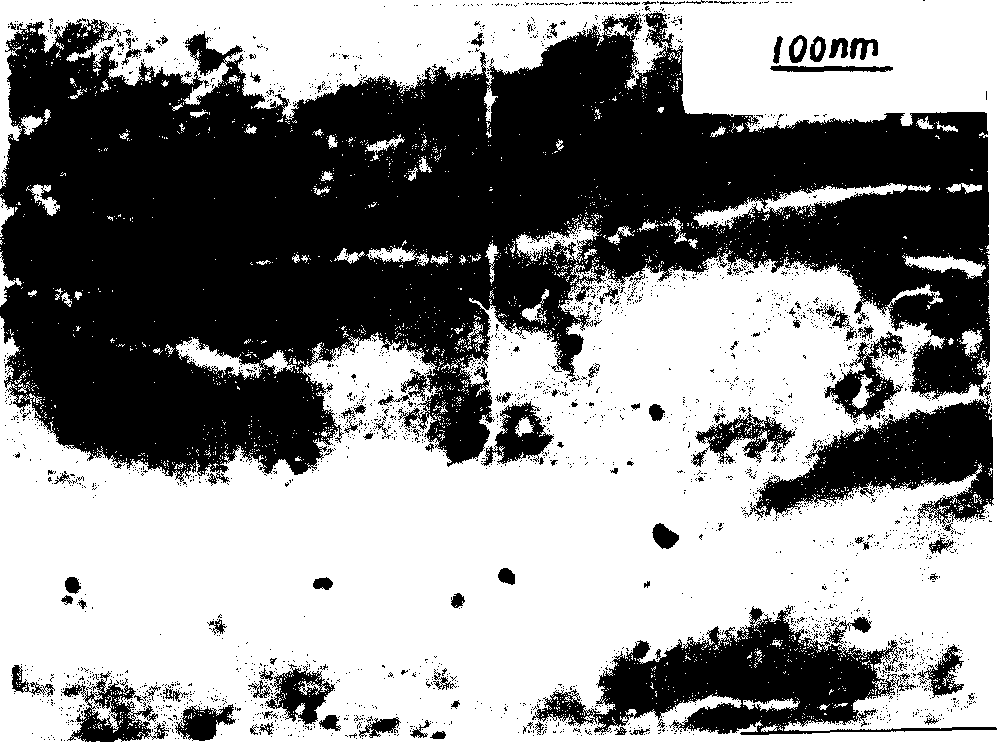

[0015] At 0.25mol / L Ce(NO 3 ) 3 Add 0.4mol / L Na to the aqueous solution 2 CO 3 Aqueous solution, burning temperature is 600 ℃, other conditions are the same as embodiment 1, and the average particle diameter is 20nm CeO 2 ,Such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com