Method for preparing metal-organic framework films based on self transformation of basic carbonates

An organic framework and carbonate technology, applied in the field of membrane separation, to achieve the effect of being conducive to large-scale popularization and application, easy to implement, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of porous copper substrate requires foamed copper (specification: 120PPI, 1mm thick); preparation of basic copper carbonate nano-array requires sodium bicarbonate (NaHCO 3 , molecular weight is 84.01), ammonium persulfate ((NH 4 ) 2 S 2 o 8 , molecular weight 228.2); the organic ligand for preparing HKUST-1 membrane is trimesic acid (C 9 h 6 o 6 , molecular weight is 210.14), solvent is ethanol and water.

[0027] Preparation conditions and methods:

[0028] (1) The copper foam is pressed into a porous copper substrate with a substrate area of 4.9cm 2 , washed with ethanol, hydrochloric acid and deionized water respectively;

[0029] (2) Take 6mL of 0.2mol / L basic sodium carbonate solution, 6mL of 0.02mol / L ammonium persulfate solution and 48mL of deionized water to prepare a mixed solution;

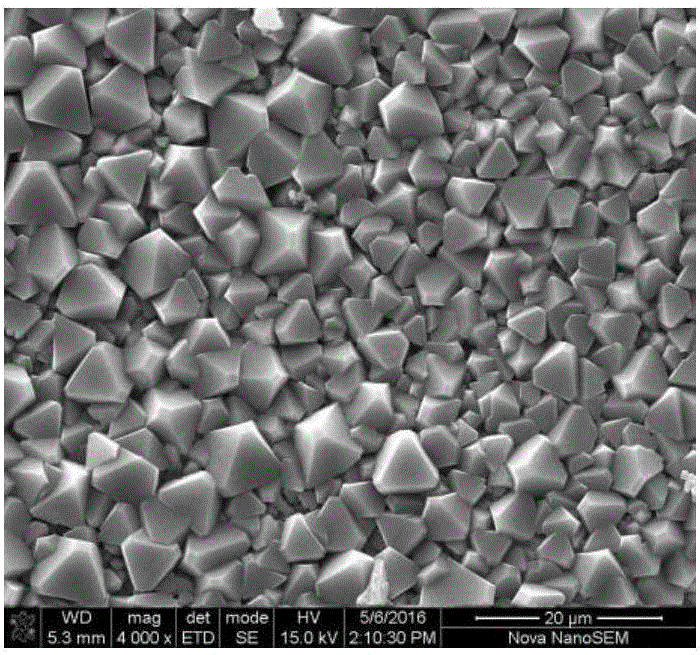

[0030] (3) Put the copper substrate of step (1) vertically into the mixed solution of step (2), and take out the copper substrate and wash it with deionized...

Embodiment 2

[0034] Preparation of porous copper substrate requires foamed copper (specification: 120PPI, 1mm thick); preparation of basic copper carbonate nano-array requires sodium bicarbonate (NaHCO 3 , molecular weight is 84.01), ammonium persulfate ((NH 4 ) 2 S 2 o 8 , molecular weight 228.2); the organic ligand for preparing HKUST-1 membrane is trimesic acid (C 9 h 6 o 6 , molecular weight is 210.14), solvent is ethanol and water.

[0035] Preparation conditions and methods:

[0036] (1) The copper foam is pressed into a porous copper substrate with a substrate area of 4.9cm 2 , washed with ethanol, hydrochloric acid and deionized respectively for use;

[0037] (2) Take 6mL of 0.2mol / L basic sodium carbonate solution, 6mL of 0.02mol / L ammonium persulfate solution and 48mL of deionized water to prepare a mixed solution;

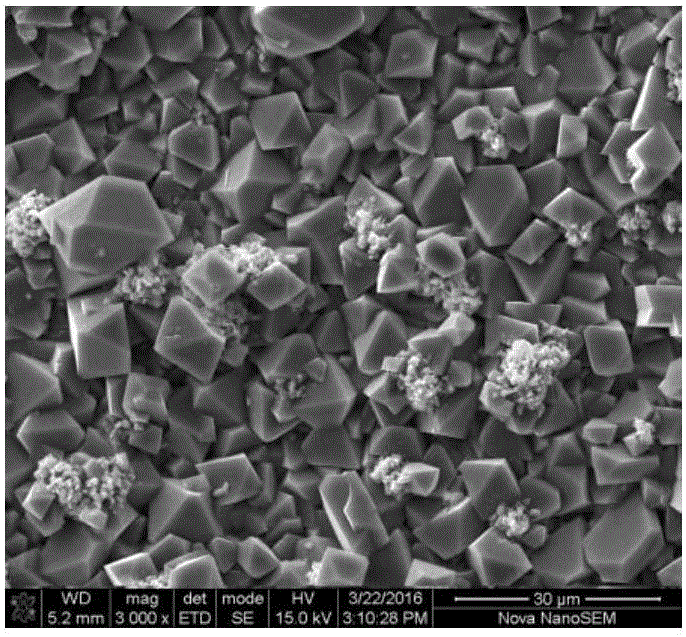

[0038] (3) Put the copper substrate of step (1) vertically into the mixed solution of step (2), and take out the copper substrate and wash it with deioniz...

Embodiment 3

[0042] Copper foam (specification: 120PPI, 1mm thick) is needed to prepare a porous copper substrate; cobalt nitrate hexahydrate (Co(NO 3 )·6H 2 O, molecular weight 291.1), urea (CO(NH 2 ) 2 , molecular weight 60.06); preparation of Co 3 (HCOO) 6 The organic ligand of the membrane is formic acid (HCOOH, the molecular weight is 46.03), and the solvent is N,N-dimethylformamide.

[0043] Preparation conditions and methods:

[0044] (1) The copper foam is pressed into a porous copper substrate with a substrate area of 4.9cm 2 , washed with ethanol, hydrochloric acid and deionized respectively for use;

[0045] (2) 1.164g of cobalt nitrate hexahydrate and 1.2g of urea were dissolved in 40mL of deionized water to prepare a mixed solution;

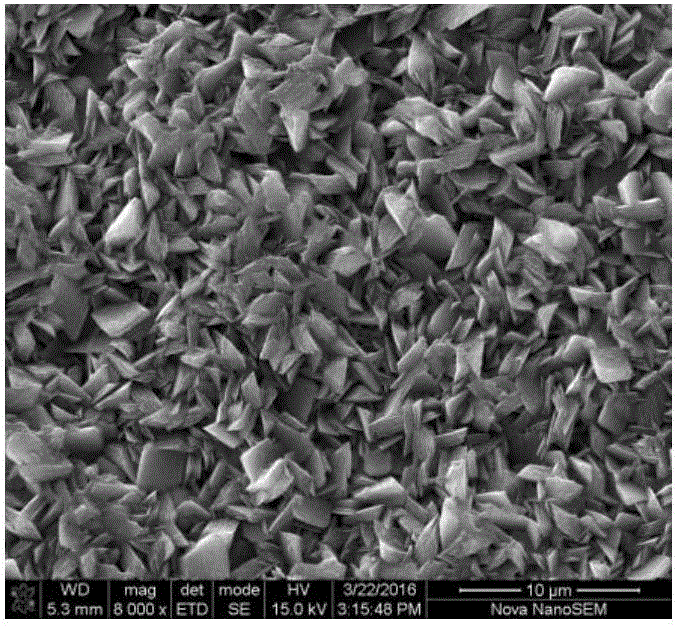

[0046] (3) Put the copper substrate in step (1) vertically into the mixed liquid in step (2), heat it at 95°C for 10 hours, take out the copper substrate, wash it with deionized water, then wash it with ethanol, and air-dry it at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com