Solidification and pore forming method for coal rock stratum containing weak structural bodies

A technology of structures and coal rock formations, which is applied in the field of solidification and pore formation in coal formations containing weak structures, can solve the problems of low porosity, casing protection material supply, heavy transportation workload, and dynamic instability, etc., and achieve high cementation The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

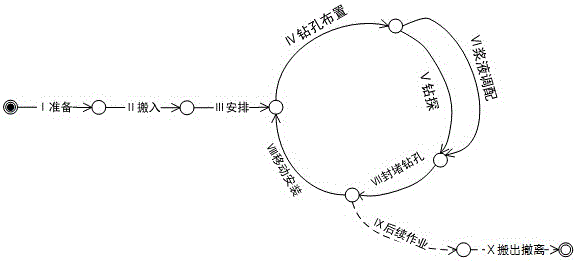

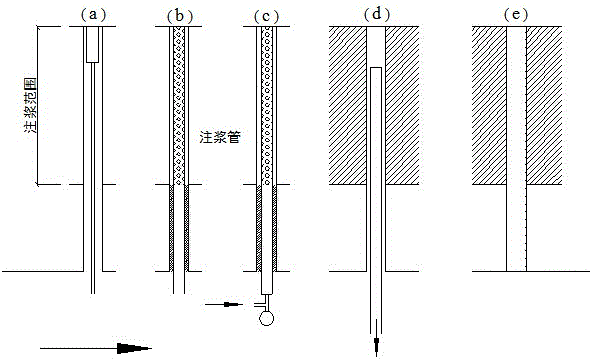

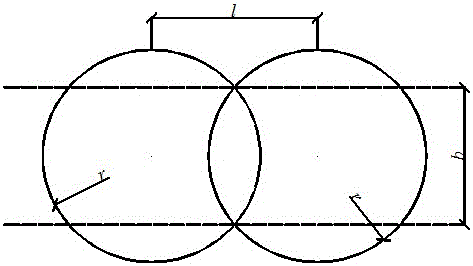

[0041] Such as figure 1 , figure 2 , image 3 As shown, the solidification pore-forming method of the coal rock layer containing weak structure comprises the following steps:

[0042] After determining the location of the drilling site, according to figure 1 Grouting construction cycle chart:

[0043] I Preparation: First of all, make preparations. Before the drilling rig is in place, check the materials, tools and equipment required for drilling and ensure that they are in place in time and working normally; security inspectors and tile inspectors measure the air composition at any time to ensure that the working environment is safe and timely. Contact dispatch office.

[0044] ⅡMoving in: After the preparation work is completed, carry out the moving in work: level off and padded the installation site, move in and install the drilling equipment.

[0045] Ⅲ Arrangeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com