Method for treating and recycling high-salt oil-field wastewater

A technology of oil extraction wastewater and high salt, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high cost, membrane calcification, and fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

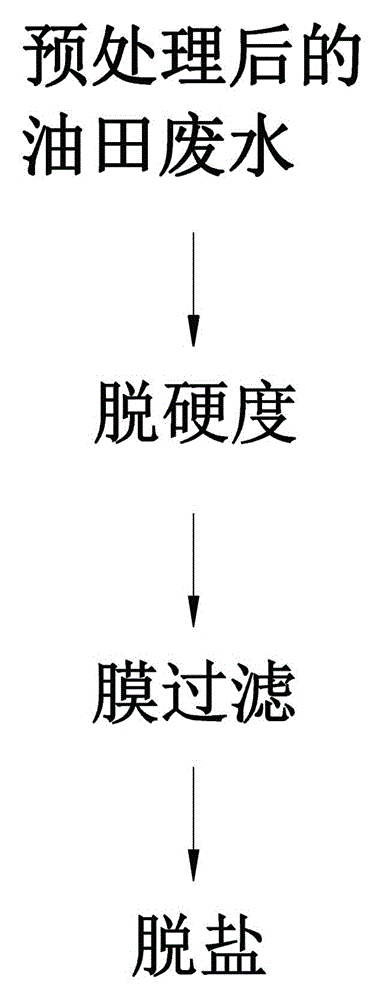

[0033] A method for processing and recycling high-salt oil production wastewater includes the following steps:

[0034] 1. De-hardness

[0035] Add lime milk and sodium carbonate to the wastewater containing calcium ion 3000mg / L, magnesium ion 500mg / L, sodium ion 8000mg / L, chloride ion 10000mg / L, oil content 300mg / L, and COD 500mg / L. The coagulant and flocculant make calcium carbonate and magnesium carbonate precipitate, and the calcium carbonate and magnesium carbonate precipitate are removed by precipitation separation, so that the concentration of calcium and magnesium ions is controlled to be less than 80mg / L. Hardness removal also includes a calcium carbonate precipitation treatment process, through which calcium carbonate is heated and oxidized to decompose into oxygen calcium.

[0036] 2. Membrane filtration

[0037] After filtering and clarifying the oil production wastewater after dehardening in step 1, it is filtered through membrane to remove particulate impurities. Among...

Embodiment 2

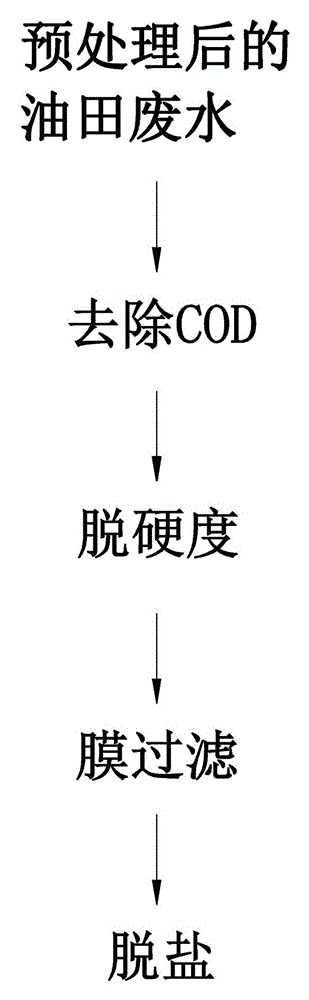

[0043] A method for processing and recycling high-salt oil production wastewater includes the following steps:

[0044] 1. De-hardness

[0045] Add lime milk and sodium carbonate to the oil production wastewater containing 200mg / L calcium ion, 20mg / L magnesium ion, 200mg / L sodium ion, 200mg / L chloride ion, 30~300mg / L oil content and 100mg / L COD Cooperate with coagulant and flocculant to make calcium carbonate and magnesium carbonate precipitate. After precipitation separation, the calcium carbonate and magnesium carbonate precipitate are removed, so that the concentration of calcium and magnesium ions is controlled to be less than 80mg / L. Hardness removal also includes a calcium carbonate precipitation treatment process, through which calcium carbonate is heated and oxidized to decompose into oxygen calcium.

[0046] 2. Remove COD

[0047] After removing the hardness in step 1, the COD concentration in the wastewater is reduced by removing the COD process of the oil production wastew...

Embodiment 3

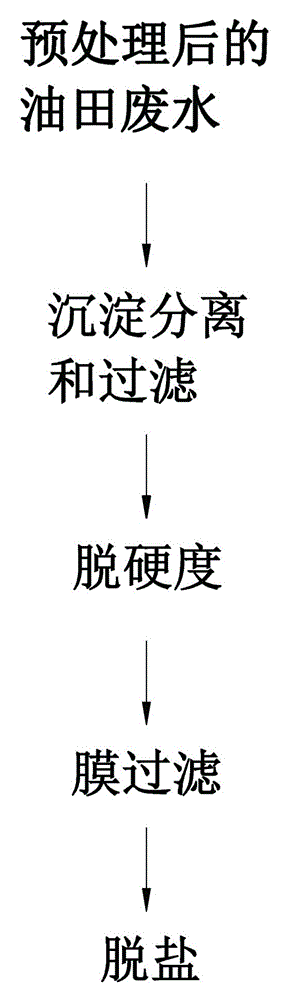

[0055] A method for processing and recycling high-salt oil production wastewater includes the following steps:

[0056] 1. De-hardness

[0057] Add lime milk and sodium carbonate to the oil production wastewater containing 1500mg / L of calcium ion, 250mg / L of magnesium ion, 4000mg / L of sodium ion, 5000mg / L of chloride ion, 150mg / L of oil and 250mg / L of COD. The coagulant and flocculant make calcium carbonate and magnesium carbonate precipitate, and the calcium carbonate and magnesium carbonate precipitate are removed by precipitation separation, so that the concentration of calcium and magnesium ions is controlled to be less than 80mg / L. Hardness removal also includes a calcium carbonate precipitation treatment process, through which calcium carbonate is heated and oxidized to decompose into oxygen calcium.

[0058] 2. Separation and filtration of precipitation

[0059] The oil production wastewater after de-hardening in step 1 undergoes precipitation separation and filtration steps t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com