Two-stage reverse osmosis regenerative heat source tower heat pump system

A heat source tower heat pump and regeneration system technology, applied in air conditioning systems, heating methods, household heating and other directions, can solve the problems of air source heat pump evaporator frosting, large irreversible loss, large mechanical energy loss, etc., to increase the scope of application, Fewer system links and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

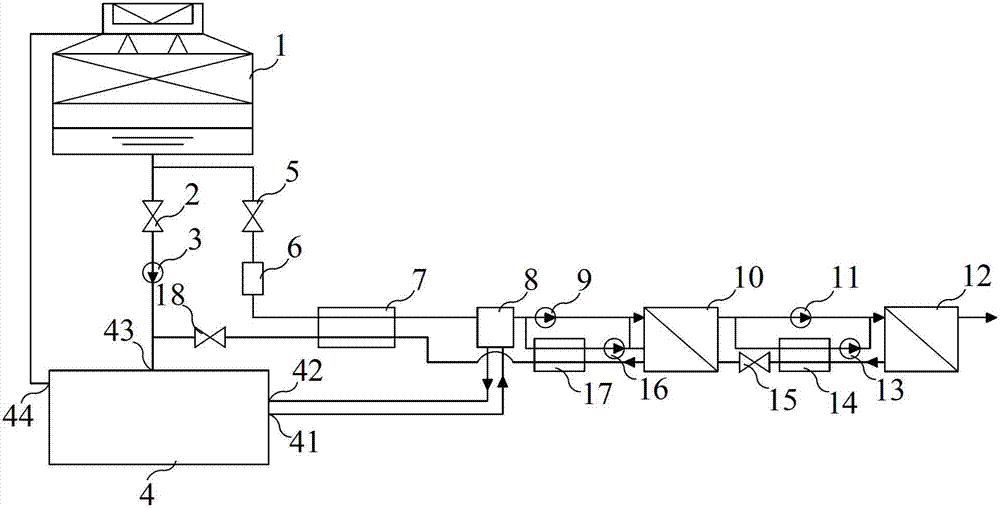

[0021] Implementation example 1, figure 1 A heat source tower heat pump system with two-stage reverse osmosis regeneration is given, including heat source tower 1, regulating valve Ⅰ 2, liquid circulation pump 3, heat pump unit 4, regulating valve Ⅱ 5, security filter 6, solution heat exchanger 7, and regenerator Cooler 8, first high-pressure pump 9, first reverse osmosis device 10, second high-pressure pump 11, second reverse osmosis device 12, second booster pump 13, second energy recovery device 14, regulating valve III15, first Booster pump 16, first energy recovery device 17 and regulating valve IV18.

[0022] The heat source tower 1 described above is provided with a sprayer, a fresh air channel, and a solution storage tank in sequence from top to bottom; a working medium (antifreeze solution or water) is stored in the solution storage tank; the solution heat exchanger 7, the second energy The recovery device 14 and the first energy recovery device 17 are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com