Method for treating ammonia nitrogen wastewater

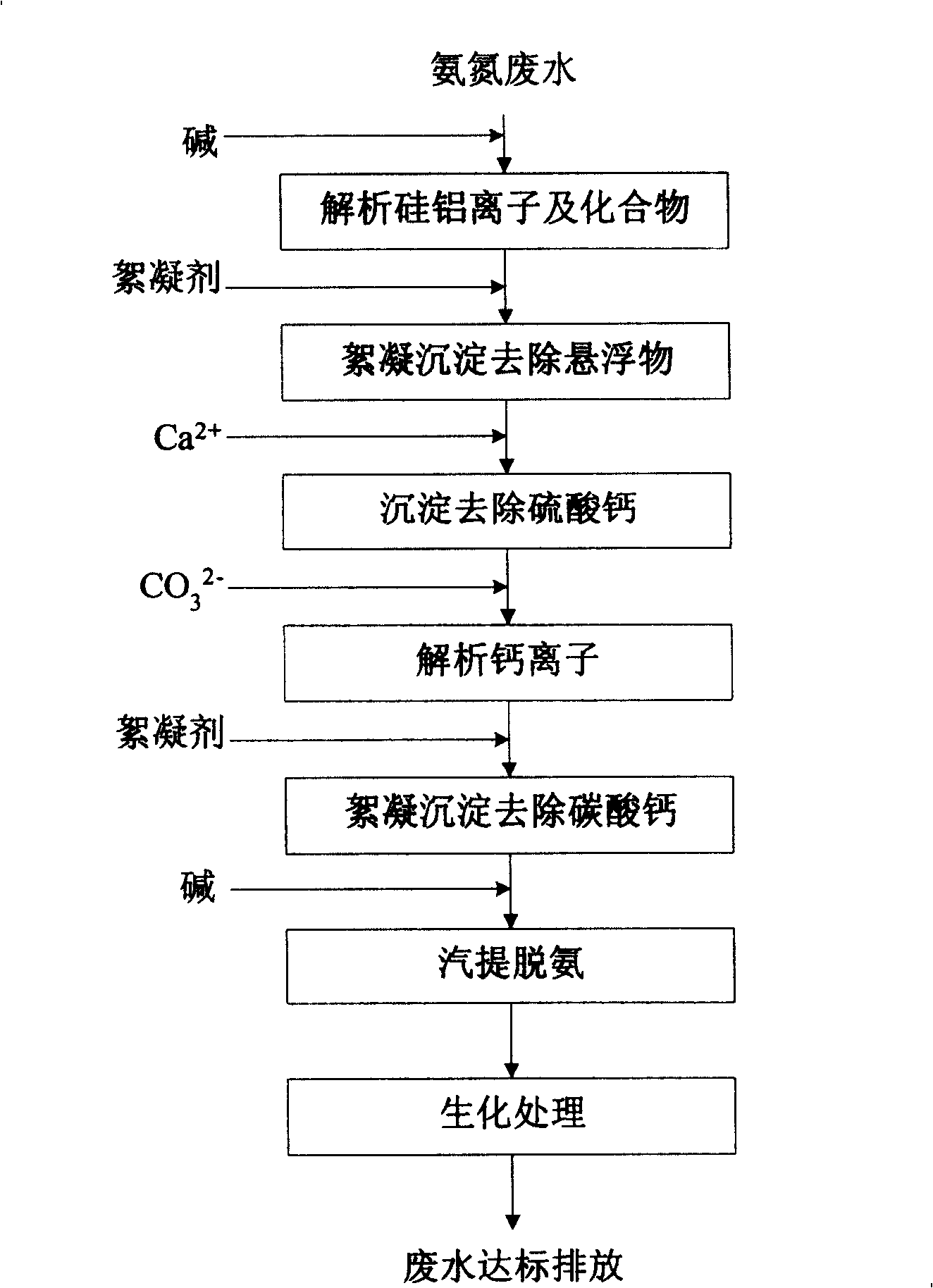

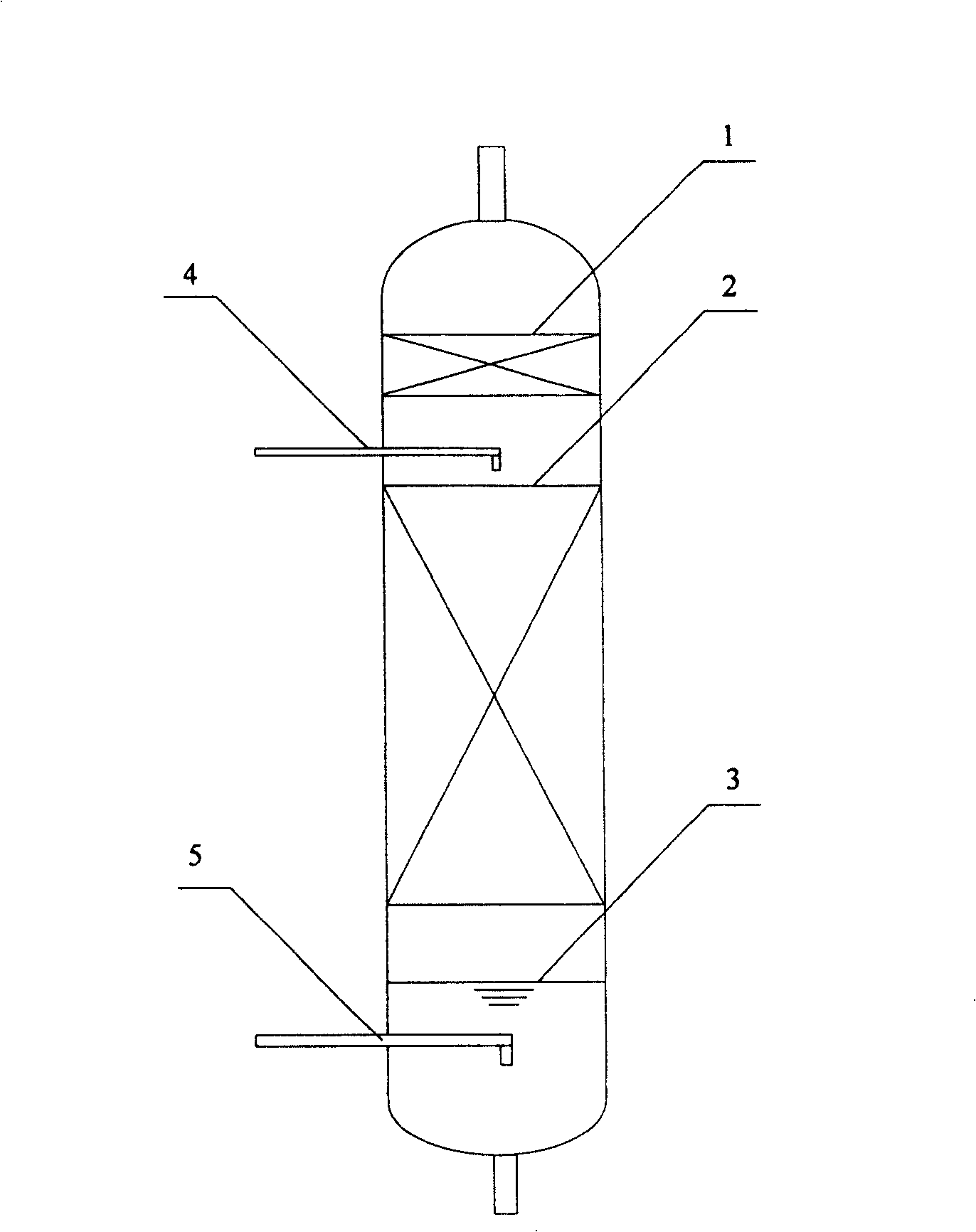

A treatment method and technology for ammonia nitrogen wastewater are applied in the field of treatment of high-concentration ammonia nitrogen wastewater, which can solve problems such as tower blockage, scaling, and poor removal of suspended solids, and achieve the effects of avoiding scaling and tower blockage and reducing the cost of alkali addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Remove suspended solids and soluble silicon-aluminum substances.

[0052] A refinery catalyst production wastewater containing dissolved SiO 2 and Al 3+ and suspended matter, the main component of the suspended matter is SiO 2 and Al(OH) 3 , Al in wastewater 3+ The concentration is 323.4mg / L, SiO 2 The concentration is 124.4mg / L.

[0053] Add sodium hydroxide to the wastewater to make the pH value 6.0; then add flocculant polyacrylamide, the concentration of which is 10mg / L; after flocculation and precipitation, Al in the wastewater 3+ The concentration is 0.49mg / L, SiO 2 The concentration is 40.5mg / L.

Embodiment 2~14

[0055] Remove suspended solids and dissolved silicon-aluminum substances.

[0056] The type of alkali, adjusted pH, concentration of flocculant, and flocculation temperature were changed, and others were the same as in Example 1. The results of wastewater treatment are shown in Table 1.

[0057] Table 1

[0058]

Embodiment 15

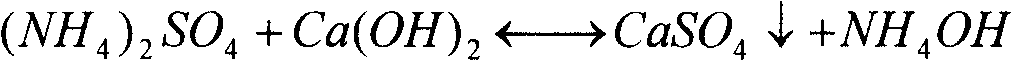

[0060] Removal of acidic substances SO 4 2- .

[0061] A kind of oil refinery catalyst production wastewater, after removing suspended solids and soluble silicon-aluminum substances, the SO in wastewater 4 2- The concentration is 43200mg / L.

[0062] Adding calcium hydroxide to wastewater, the added Ca 2+ with SO 4 2- The molar ratio is 0.5:1, after precipitation, SO in wastewater 4 2- The concentration is 19150mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com