New process for fixing carbon dioxide

A carbon dioxide, new process technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of aggravating the greenhouse effect, difficult to absorb, etc. The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

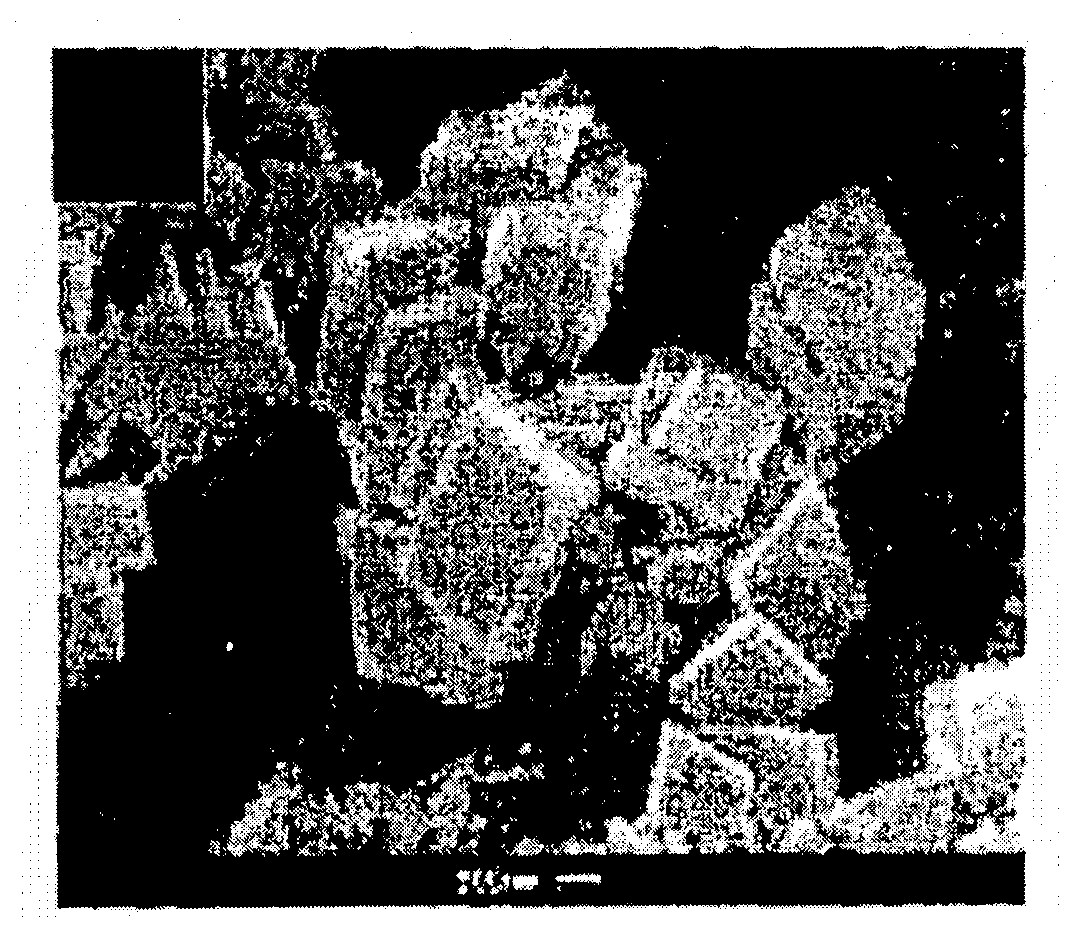

[0032] The slurry is prepared by mixing calcium carbide slag: water (mass ratio) = 1:15. Add 2mol / L ammonium chloride solution to dissolve until the pH of the solution is around 8. Filter to obtain a mixed solution of calcium chloride and ammonia water with a solution concentration of 2%. in CO 2 In the absorber, sodium dodecylbenzenesulfonate is added in the filtrate, and the addition of sodium dodecylbenzenesulfonate is controlled to be 0.2% of the calcium carbonate quality that generates. Then feed 6% (volume ratio) CO into the filtrate 2 Gas, the gas flow rate is 10ml / min, and the reaction temperature is controlled at 5°C. After the reaction was finished, the product was analyzed by a scanning electron microscope after filtration and drying, and the crystal form was figure 1 Calcite-type calcium carbonate in shape.

Embodiment 2

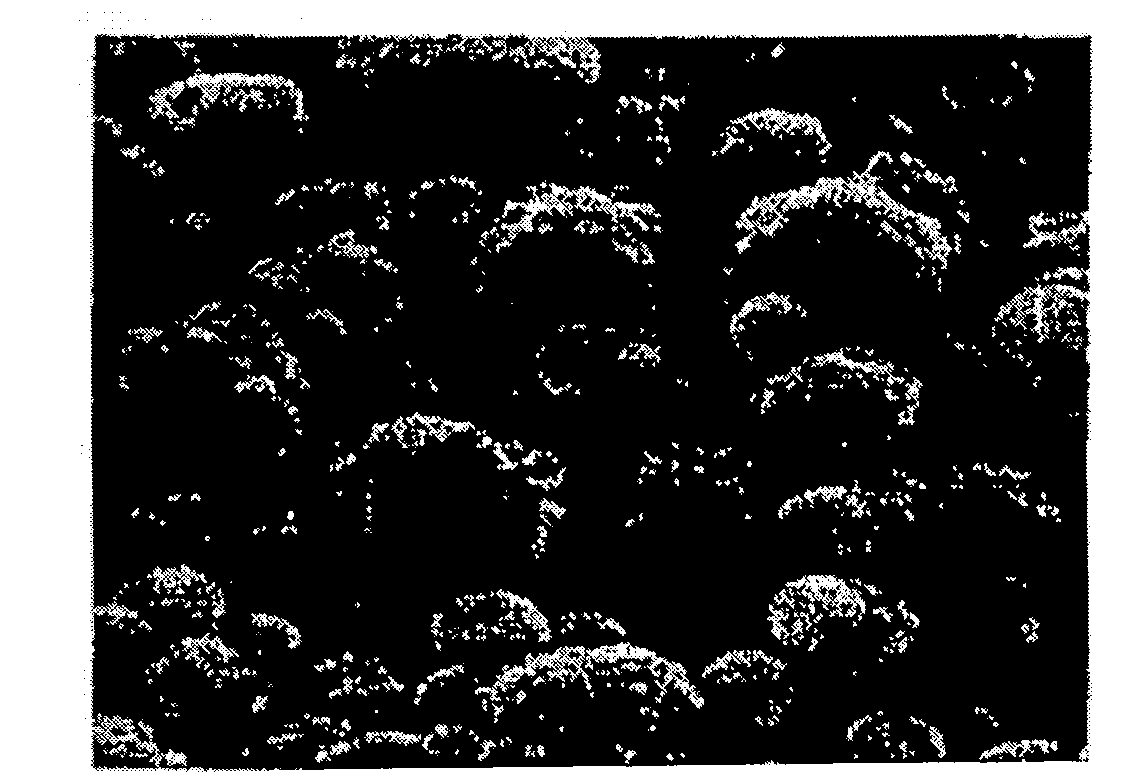

[0034] The slurry is prepared by mixing calcium carbide slag: water (mass ratio) = 1:20. Add 3mol / L ammonium chloride solution to dissolve until the pH of the solution is around 8. Filter to obtain a mixed solution of calcium chloride and ammonia water with a solution concentration of 4%. in CO 2 In the absorber, sodium dodecylbenzenesulfonate is added in the filtrate, and the addition of sodium dodecylbenzenesulfonate is controlled to be 0.2% of the calcium carbonate quality that generates. Then feed 10% (volume ratio) CO into the filtrate 2 Gas, the gas flow rate is 15ml / min, and the reaction temperature is controlled to be 12°C. After the reaction was finished, the product was analyzed by a scanning electron microscope after filtration and drying, and the crystal form was figure 2 The shape of vaterite calcium carbonate.

Embodiment 3

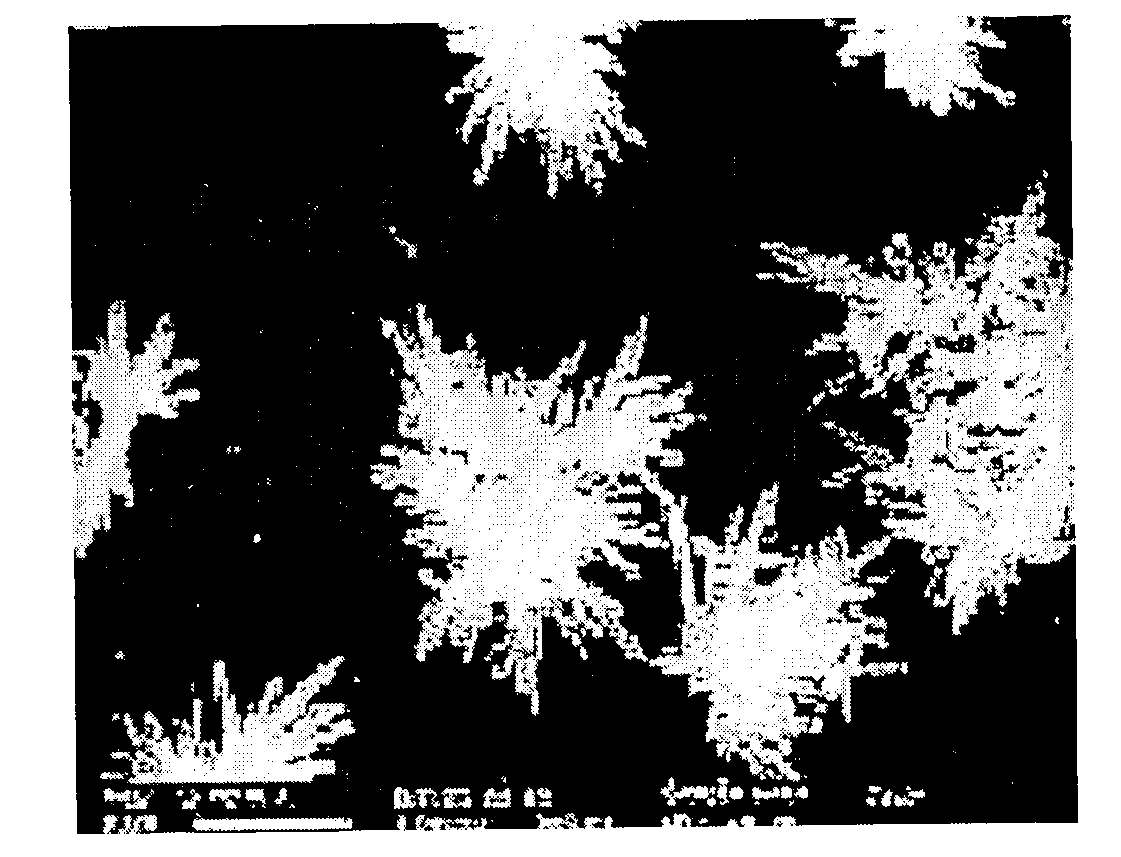

[0036] The slurry is prepared by mixing calcium carbide slag: water (mass ratio) = 1:25. Add 5mol / L ammonium chloride solution to dissolve until the pH of the solution is around 8. Filter to obtain a mixed solution of calcium chloride and ammonia water with a solution concentration of 12%. in CO 2 In the absorber, sodium dodecylbenzenesulfonate is added in the filtrate, and the addition of sodium dodecylbenzenesulfonate is controlled to be 0.2% of the calcium carbonate quality that generates. Then feed 25% (volume ratio) CO into the filtrate 2 Gas, the gas flow rate is 20ml / min, and the reaction temperature is controlled to be 75°C. After the reaction was finished, the product was analyzed by a scanning electron microscope after filtration and drying, and the crystal form was image 3 The shape of aragonite calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com