Novel transition metal ion-doped energy-saving glass and preparation method thereof

A transition metal ion, energy-saving glass technology, which is applied in the field of new transition metal ion-doped energy-saving glass and its preparation, can solve the problem that energy-saving glass cannot take into account heat insulation and safety, and achieves the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Sample 1: (P 2 o 5 ) 0.56 (SiO 2 ) 0.1 (GeO 2 ) 0.05 (Al 2 o 3 ) 0.20 (Li 2 O) 0.10 (Cu 2 O) 0.0025 (Fe 2 o 3 ) 0.0025

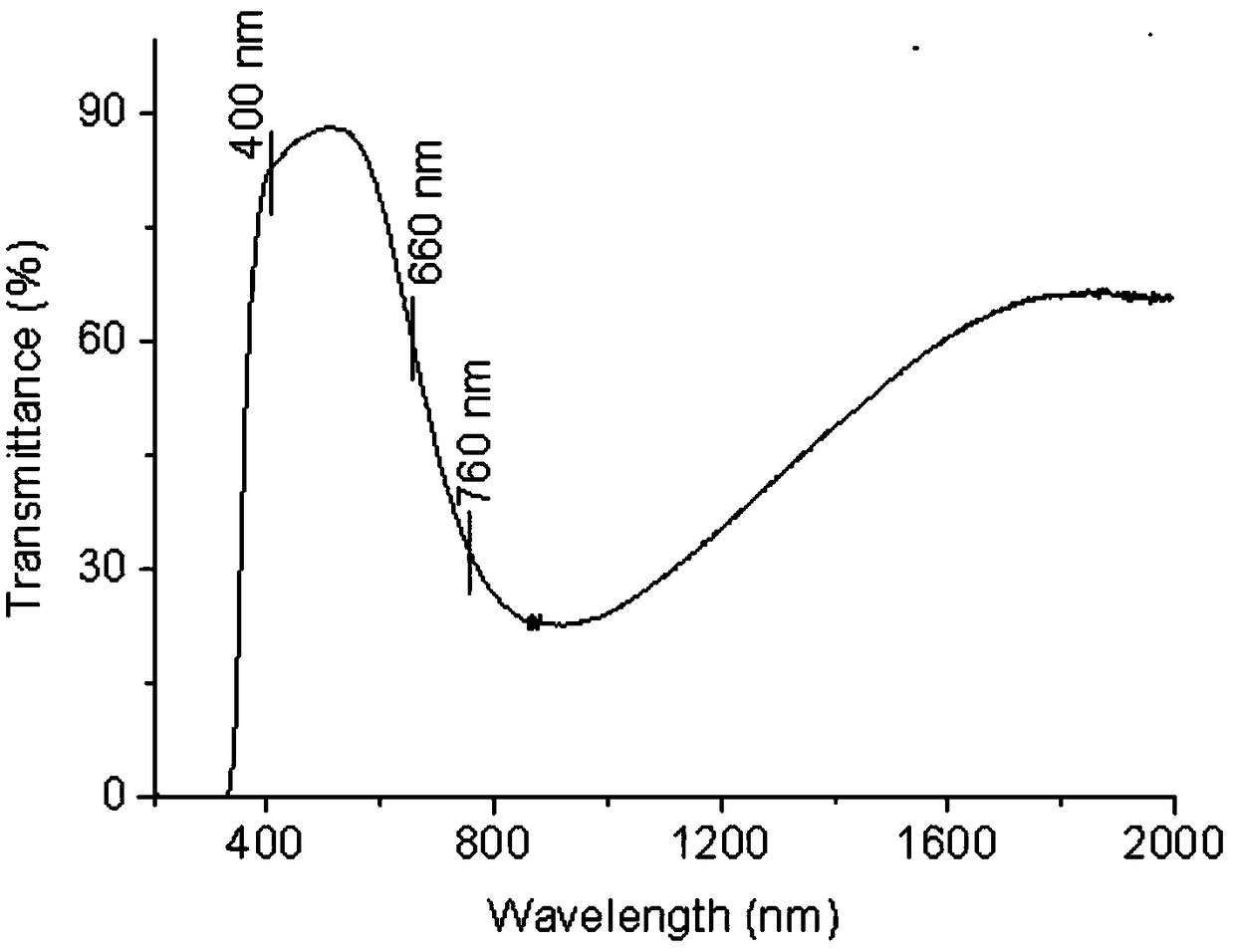

[0032] The raw material used is NH 4 h 2 PO 4 , SiO 2 、GeO 2 、Al 2 o 3 , Li 2 CO 3 、Cu 2 O and Fe 2 o 3 . After the above raw materials are pre-mixed evenly by grinding, they are heated to 1450°C at 5°C / min in an air atmosphere in an electric furnace, taken out immediately, poured on a copper plate at 290°C for quenching, and then annealed at 290°C for 3 hours to obtain sample 1, sample 1 The UV-Vis absorption spectrum of figure 1 It can be seen that sample 1 has no obvious absorption in the visible light region and only has certain absorption in the red light region (660-760nm). Infrared light has strong absorption and can be used in occasions that do not require high quality of natural light.

Embodiment 2

[0034] Sample 2: (P 2 o 5 ) 0.56 (SiO 2 ) 0.1 (GeO 2 ) 0.05 (Al 2 o 3 ) 0.20 (Li 2 O) 0.10 (Cu 2 O) 0.0025 (Fe 2 o 3 ) 0.005

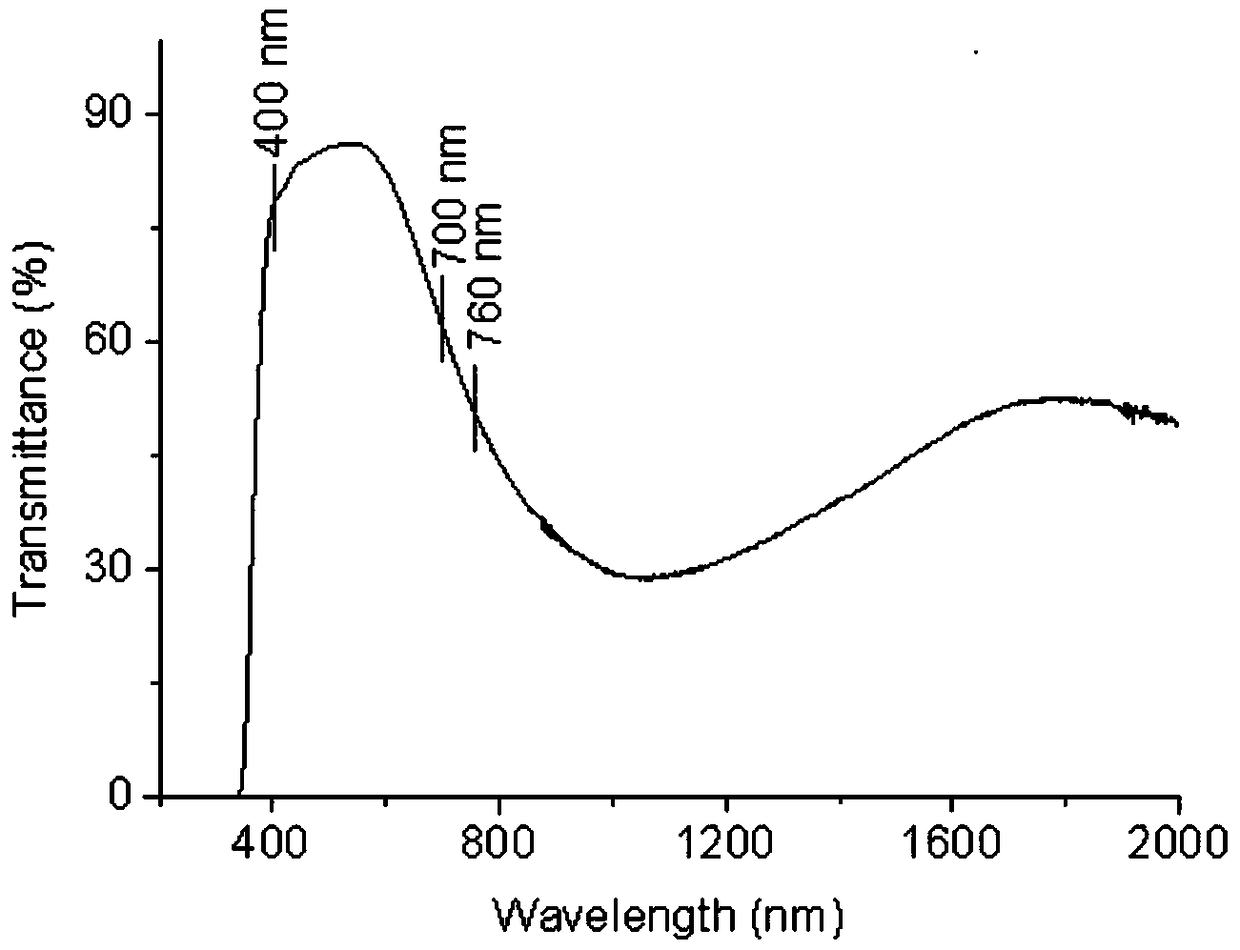

[0035] The raw material used is NH 4 h 2 PO 4 , SiO 2 、GeO 2 、Al 2 o 3 , Li 2 CO 3 、Cu 2 O, Fe 2 o 3 ; After the raw materials are pre-mixed evenly by grinding, they are heated to 1450°C at 5°C / min in an air atmosphere in an electric furnace, taken out immediately, poured on a copper plate at 290°C for quenching, and then annealed at 290°C for 3 hours to obtain sample 2; sample 2 The UV-Vis absorption spectrum of figure 2It can be seen that sample 2 has no obvious absorption in the visible light region, but has certain absorption in the red light region of 700-760 nm, and sample 2 is transparent and bluish. Sample 2 has a strong absorption of ultraviolet light of 200-365nm, and a strong absorption of near-infrared light of 760-1640nm. It can be seen that sample 2 can be used in almost all occasions that require energy-savi...

Embodiment 3

[0037] Sample 3: (P 2 o 5 ) 0.56 (SiO 2 ) 0.1 (GeO 2 ) 0.05 (Al 2 o 3 ) 0.20 (Li 2 O) 0.10 (TiO 2 ) 0.01 (Fe 2 o 3 ) 0.005

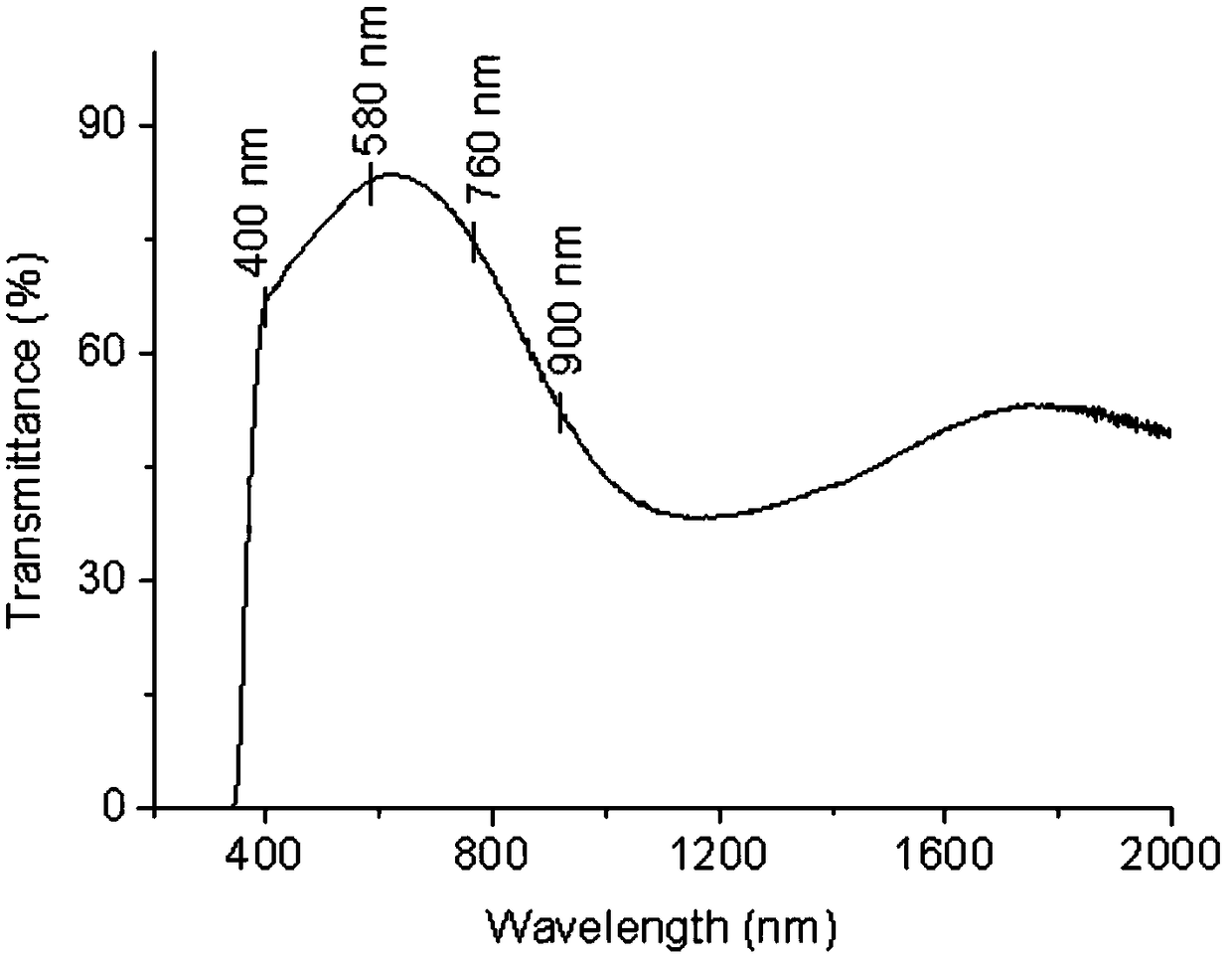

[0038] The raw material used is NH 4 h 2 PO 4 , SiO 2 、GeO 2 、Al 2 o 3 , Li 2 CO 3 , Fe 2 o 3 、TiO 2 . After the raw materials were ground and pre-mixed uniformly, they were heated to 1450°C at 5°C / min in an air atmosphere in an electric furnace and immediately taken out, poured on a copper plate at 290°C for quenching, and then annealed at 290°C for 3 hours to obtain sample 3; UV-Vis absorption spectrum, such as image 3 As shown, sample 3 has no obvious absorption in the visible light region and only has certain absorption in the range of 390-590nm. The sample is transparent but slightly brownish. Sample 3 has a strong absorption of ultraviolet light of 200-365nm, and a strong absorption of near-infrared light of 900-2000nm, so sample 3 can be used in almost all occasions that require energy-saving glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com