Rose Bengal-doped modified titanium concentrate photocatalyst and preparation method thereof

A technology of photocatalyst and titanium concentrate, applied in the field of photocatalytic chemistry, can solve the problems of high investment in degradation equipment and high cost of degradation operation, and achieve the effects of improving visible light catalytic activity, low preparation cost, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

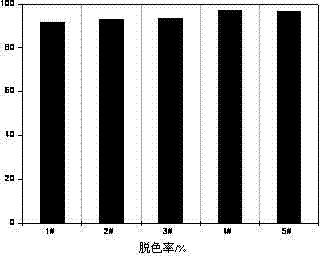

Embodiment 1

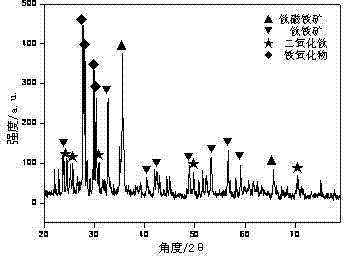

[0033] The present embodiment selects the composition of titanium concentrate raw material as TiO 2 47.01wt%, FeO 34.27wt%, Fe 2 o 3 10.55wt%, CaO 0.75wt%, SiO 2 2.89wt%, Al 2 o 3 1.34wt%, MnO0.65wt%, MgO2.54wt%.

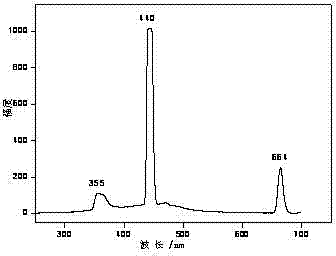

[0034] Crush the massive ilmenite concentrate, screen the ilmenite concentrate powder with a diameter of 0.5-1mm, mix the tiger red with the crushed ilmenite concentrate powder, and the mixing ratio is 2.5wt% of the titanium concentrate powder with tiger red.

[0035] Use a ball mill to dry-mix the mixed powder of titanium concentrate and tiger bengal until the average particle size is 10 μm.

[0036] Compress the mixed powder into tablets with a tablet machine.

[0037] Put the compressed sample into a muffle furnace for roasting, the roasting temperature is 100°C, the heating rate is 5°C / min, the roasting time is 2h, after the roasting is finished, it is cooled to room temperature in the air, and then ground to an average particle size of 10 μm , Obtain a...

Embodiment 2

[0046] The present embodiment selects the composition of titanium concentrate raw material as TiO 2 47.93wt%, FeO 28.61wt%, Fe 2 o 3 16.68wt%, CaO 0.8wt%, SiO 2 2.27wt%, Al 2 o 3 1.07wt%, MnO0.07wt%, MgO2.57wt%.

[0047] Crush the massive ilmenite concentrate, screen the ilmenite concentrate powder with a diameter of 0.5-1mm, mix the tiger red with the crushed ilmenite concentrate powder, and the mixing ratio is 2.5wt% of the titanium concentrate powder with tiger red.

[0048] Use a ball mill to dry-mix the mixed powder of titanium concentrate and tiger bengal until the average particle size is 12 μm.

[0049] Compress the mixed powder into tablets with a tablet machine.

[0050] Put the compressed sample into a muffle furnace for roasting, the roasting temperature is 200°C, the heating rate is 10°C / min, the roasting time is 3h, after the roasting is finished, it is cooled to room temperature in the air, and then ground to an average particle size of 12 μm , Obtain t...

Embodiment 3

[0055] The present embodiment selects the composition of titanium concentrate raw material as TiO 2 48.93wt%, FeO 32.37wt%, Fe 2 o 3 14.86wt%, CaO 0.84wt%, SiO 2 1.05wt%, Al 2 o 3 1.08wt%, MnO0.23wt%, MgO0.64wt%.

[0056] Crush the massive titanium concentrate, screen the titanium concentrate powder with a diameter of 0.5-1mm, mix the tiger red with the crushed titanium concentrate powder, and the mixing ratio is 5wt% of the titanium concentrate powder with tiger red.

[0057] Use a ball mill to dry-mix the mixed powder of titanium concentrate and tiger bengal until the average particle size is 13 μm.

[0058] Compress the mixed powder into tablets with a tablet machine.

[0059] Put the compressed sample into a muffle furnace for roasting, the roasting temperature is 300°C, the heating rate is 5°C / min, and the roasting time is 4h. After the roasting is completed, it is cooled to room temperature in the air, and then ground to an average particle size of 13 μm. , Obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com