Rhodamine B-doped modified titanium concentrate photocatalyst and preparation method thereof

A technology of photocatalyst and titanium concentrate, which is applied in the field of photocatalytic chemistry, can solve the problems of high investment in degradation equipment and high cost of degradation operation, and achieve the effects of improving visible light catalytic activity, simple process, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

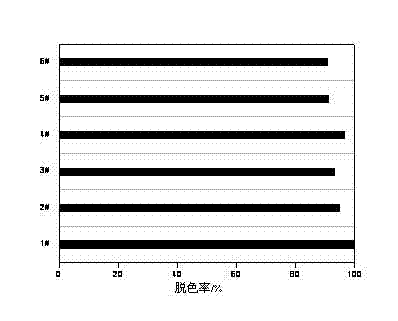

Embodiment 1

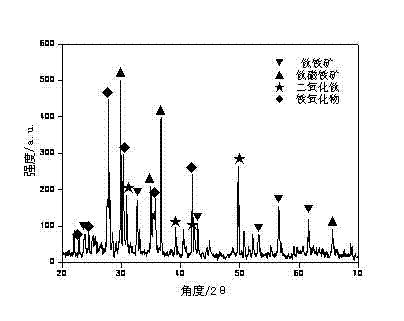

[0036] In the present embodiment, the composition of the titanium concentrate raw material is: TiO 2 52.25wt%, FeO 35wt%, Fe 2 o 3 8.72wt%, CaO 0.46wt%, SiO 2 1.01wt%, Al 2 o 3 1.23wt%, MnO1.15wt%, MgO0.18wt%.

[0037] The titanium concentrate is crushed and screened to obtain titanium concentrate powder with a diameter of 1 mm.

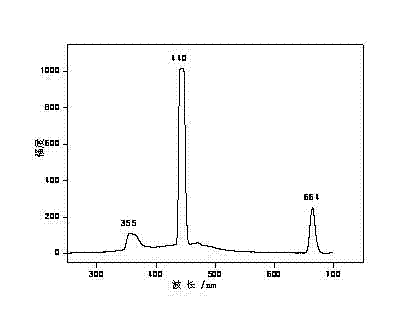

[0038] Rhodamine B is mixed with the crushed titanium concentrate powder to form a mixed powder, and the mixing ratio accounts for 2.5wt% of the titanium-containing concentrate powder according to Rhodamine B;

[0039] Add 20ml of absolute ethanol to the above mixed powder, and ultrasonically disperse for 10 minutes to form a mixed slurry;

[0040] Use a ball mill to wet mix the mixed slurry of titanium concentrate and rhodamine B into a ball mill tank, and ball mill until the average particle size is 10 μm;

[0041] Put the ball mill jar into the drying oven, dry at 70 °C for 24 h, and dry the mixed slurry into mixed powder;

[0042] Grind...

Embodiment 2

[0051] In this embodiment, select titanium concentrate raw material to be composed of: TiO 2 50.94wt%, FeO 28.59wt%, Fe 2 o 3 15.22wt%, CaO 0.75wt%, SiO 2 1.64wt%, Al 2 o 3 1.70wt%, MnO1.43wt%, MgO0.1wt%.

[0052] Crush the titanium concentrate, and obtain titanium concentrate powder with a diameter of 0.5 mm after screening;

[0053] Rhodamine B is mixed with the crushed titanium concentrate powder to form a mixed powder, and the mixing ratio accounts for 2.5wt% of the titanium-containing concentrate powder according to Rhodamine B;

[0054] Add 30ml of absolute ethanol to the mixed powder, and ultrasonically disperse for 15 minutes to form a mixed slurry;

[0055] Put the mixed slurry of titanium concentrate and rhodamine B into a ball mill tank with a ball mill, and wet-mix ball mill until the average particle size is 12 μm;

[0056] Put the ball mill jar into a drying oven and dry at 70 °C for 24 h to dry the mixed slurry into a mixed powder;

[0057] Grind the d...

Embodiment 3

[0063] In this embodiment, select titanium concentrate raw material to be composed of: TiO 2 54.5wt%, FeO 25.23wt%, Fe 2 o 3 14.3wt%, CaO 0.42wt%, SiO 2 1.95wt%, Al 2 o 3 1.98wt%, MnO1.53wt%, MgO0.09wt%.

[0064] Crushing the titanium concentrate, and obtaining titanium concentrate powder with a diameter of 0.7 mm after screening;

[0065] Rhodamine B is mixed with the crushed titanium concentrate powder to form a mixed powder, and the mixing ratio accounts for 5wt% of the titanium-containing concentrate powder according to Rhodamine B;

[0066] Add 40ml of absolute ethanol to the mixed powder, and ultrasonically disperse for 20 minutes to form a mixed slurry;

[0067] Put the mixed slurry of titanium concentrate and rhodamine B into a ball mill tank with a ball mill, and wet-mix ball mill until the average particle size is 13 μm;

[0068] Put the ball mill jar into a drying oven and dry at 70 °C for 24 h to dry the mixed slurry into a mixed powder;

[0069] Grind the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com