Foundation pit engineering waterproof curtain material based on industrial waste residue

A technology of industrial waste residue and water-stop curtain, applied in the field of civil engineering, can solve the problems of low rigidity, high cost and poor effect of flexible waterproof materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

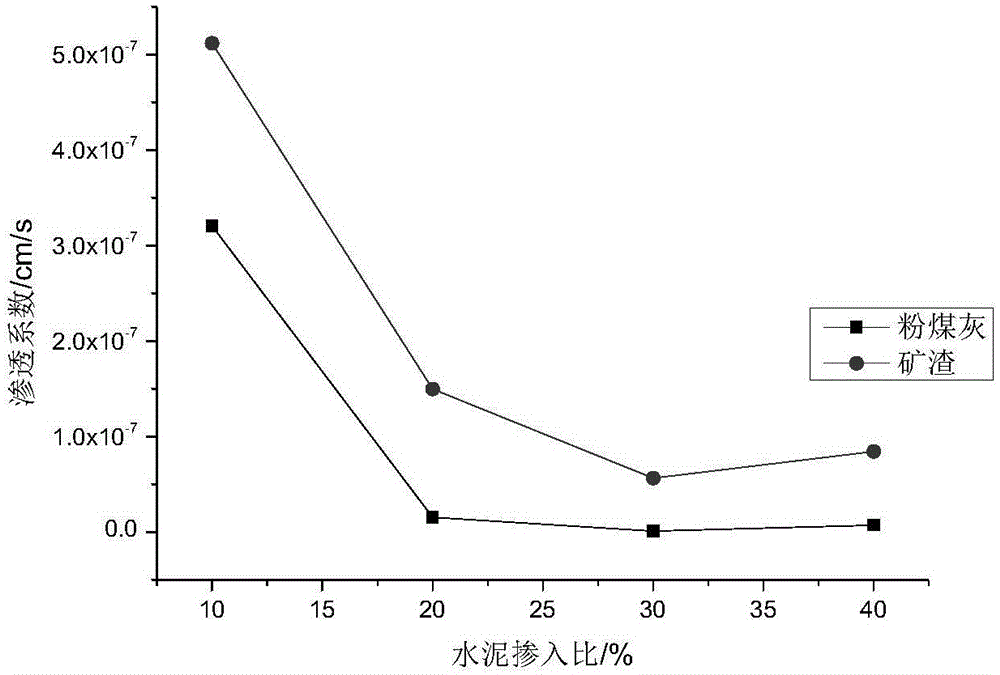

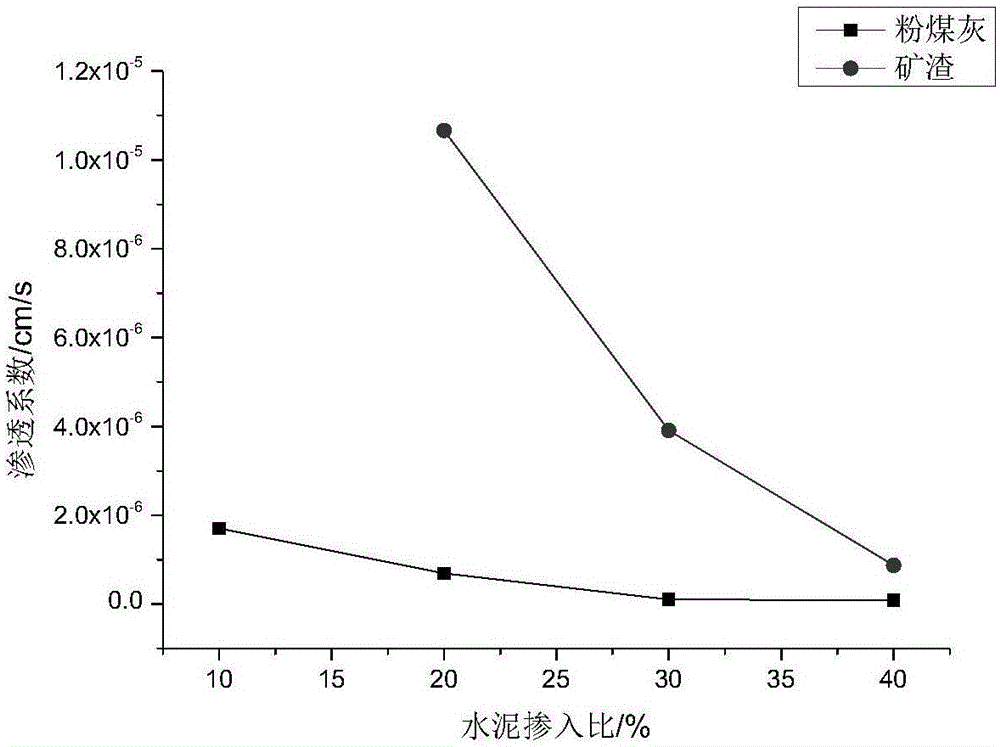

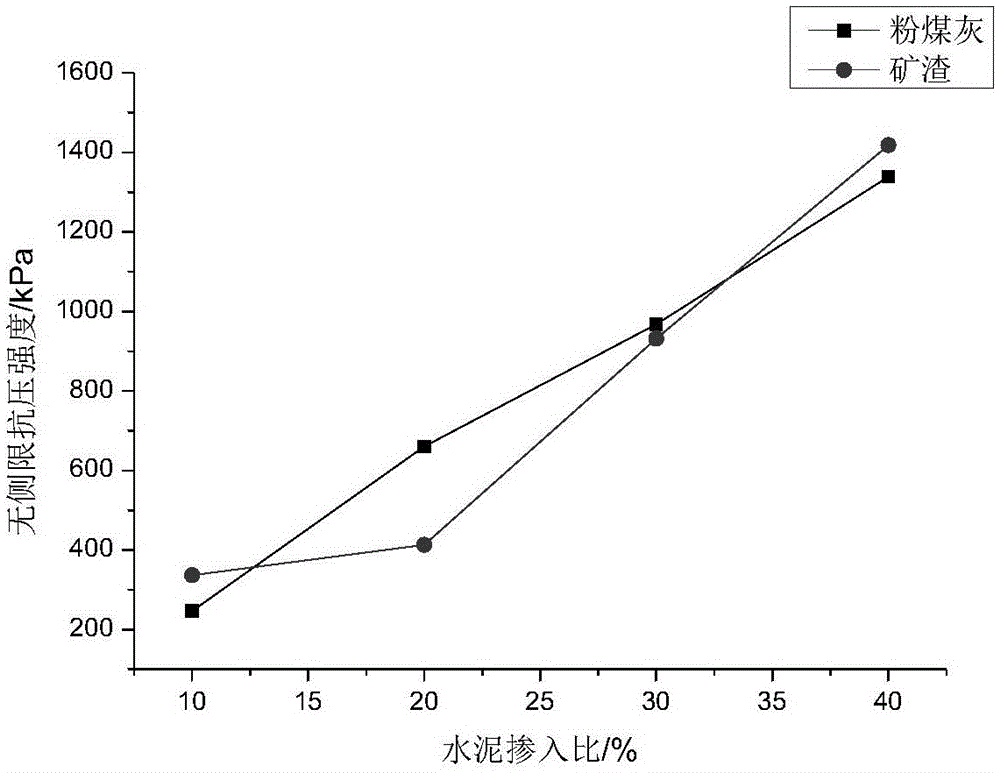

[0025] The new cement-soil material of the present invention is to use clay / sand and cement as raw materials, by adding industrial waste slag-fly ash or slag to replace part of the cement, to prepare a new cement-soil material with low permeability, including the following mass fractions Components: water: 15% to 25%, the rest is solid and water glass; the mass of water glass is 3% of the solid mass; wherein, the solid is composed of base material and curing agent, wherein the base material is clay or sand , the curing agent is composed of cement, industrial waste residue and quicklime, and the curing agent accounts for 25% of the total mass; the industrial waste residue is fly ash or slag; in the curing agent, the mass fraction of cement is 10% to 40%; The ratio of the mass fraction of quicklime to industrial waste residue is 15:100.

[0026] The specific proportioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com