Variable water level clay dam slope seepage failure occurrence condition test device and method

A test device, clay technology, applied in the direction of measuring device, soil material testing, permeability/surface area analysis, etc., can solve the problem of increasing seepage slope value and seepage damage, deteriorating clay anti-seepage performance, and inability to seepage slope of clay anti-seepage body down observation and determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

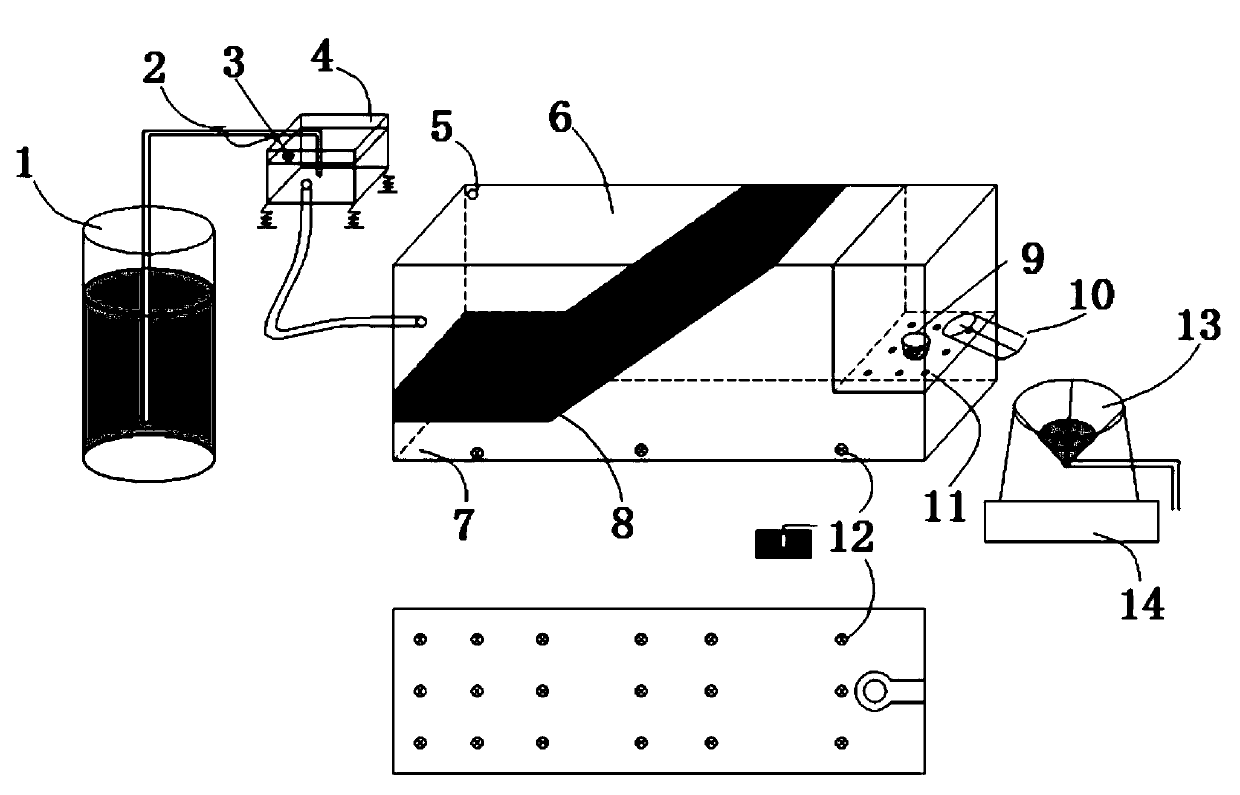

[0031] A variable water level clay dam slope seepage failure test device, the device includes a test box, the rear of the test box is divided into a closed water storage chamber 6 and a piping observation room at the tail by a partition, the observation room The top is flush with the top of the water storage chamber 6, and the bottom of the observation chamber is higher than the bottom of the water storage chamber 6; the partition is an L-shaped plate;

[0032] One end of the water pump 2 is connected to the water storage tank 1 through a pipeline, and the other end is connected to the pressure regulating water tank 4. The inside of the pressure regulating water tank 4 is provided with a valve ball 3, and the height of the valve ball 3 is adjustable; The water inlet of the water storage chamber 6 is connected with the water outlet of the pressure regulating water tank 4 through a pipeline, and the water supply and the water pressure are adjusted through the pressure regulating ...

Embodiment 2

[0046] This embodiment is the test method of the variable water level clay dam slope seepage damage occurrence condition test device in embodiment one, comprising the following steps:

[0047] 1) Lay a sandy soil layer 7 on the bottom layer of the water storage chamber 6, and embed piezometer sensors 12 in the sandy soil layer 7. After the sandy soil layer 7 is compacted, the piezometer sensors 12 are arranged at intervals along the axial direction on the surface, and then The clay covering layer 10 is laid on the surface layer, and colored glass beads can also be embedded in the sand layer 7 simultaneously.

[0048] 2) Set the height of the pressure regulating water tank 4 and the valve ball 3, turn on the water pump 2 to pump water from the water storage tank 1 into the pressure regulating water tank 4, and the water flow enters the water storage chamber 6 through the pipeline for testing.

[0049] 3) Choose a small water head for the initial height, and observe the seepage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com