Simulation test device and test method of sand inrush

A simulation test and sand breaking technology, which is applied to mining equipment, earth square drilling, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

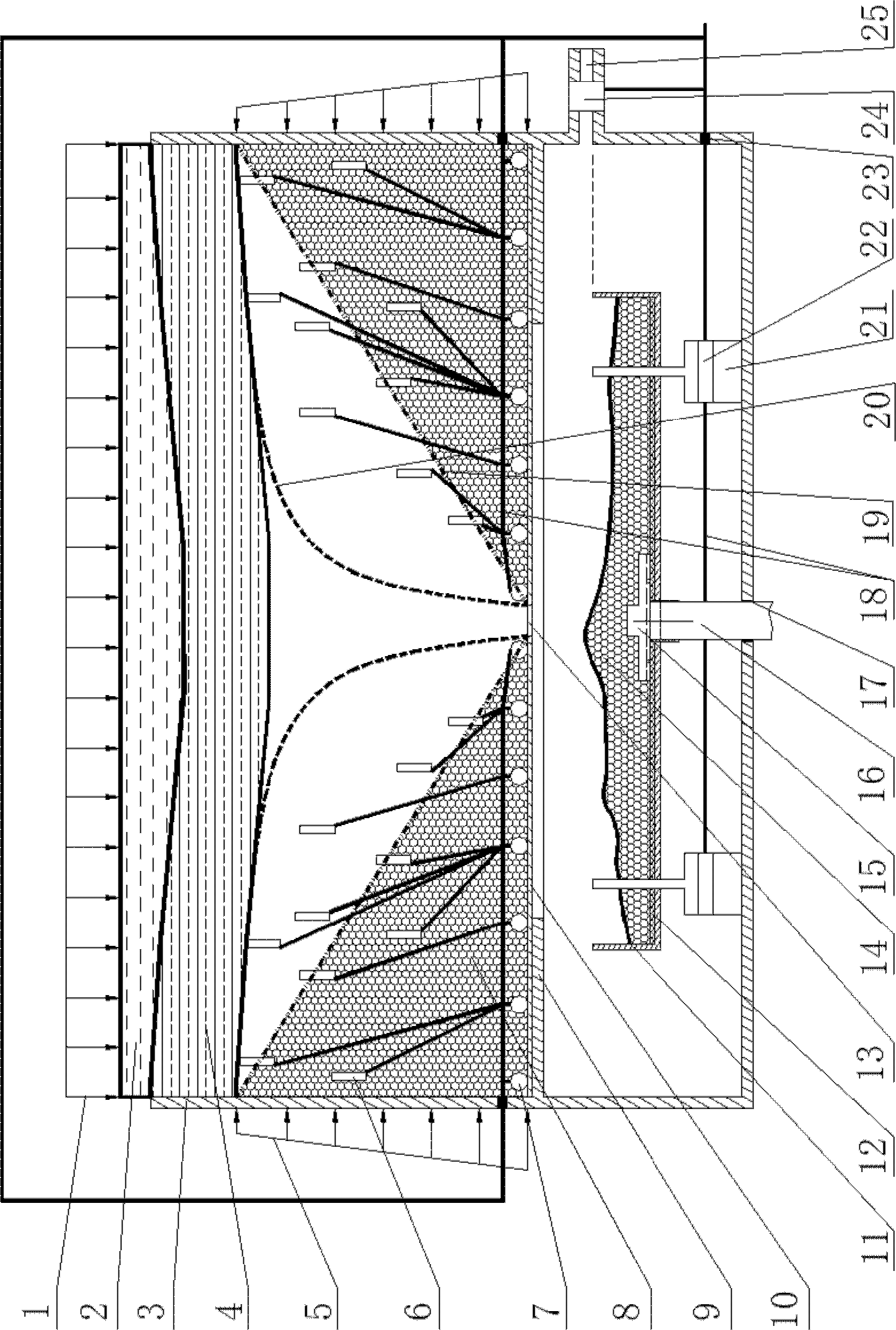

[0048] A test method for a sand burst simulation test device, the steps are:

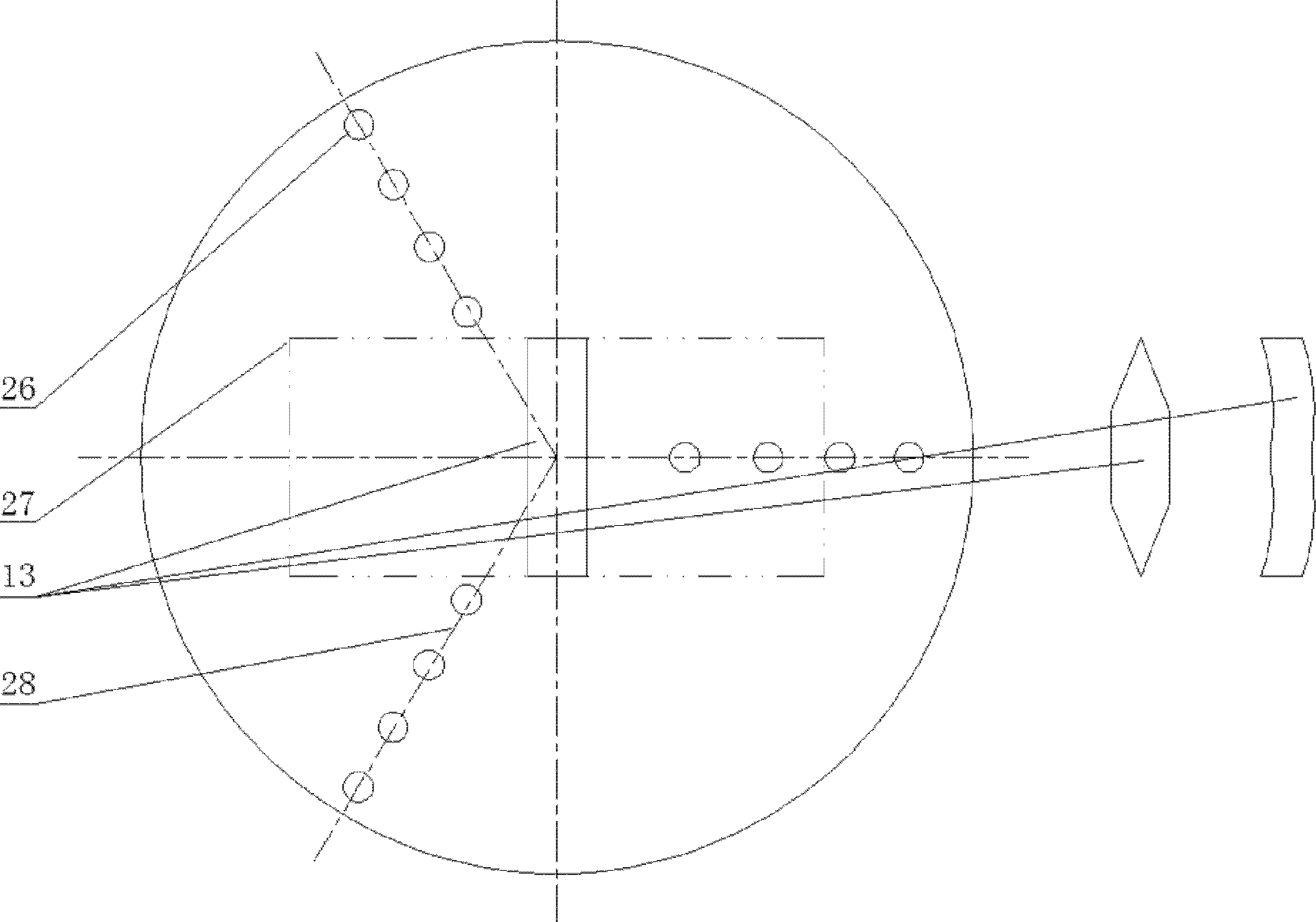

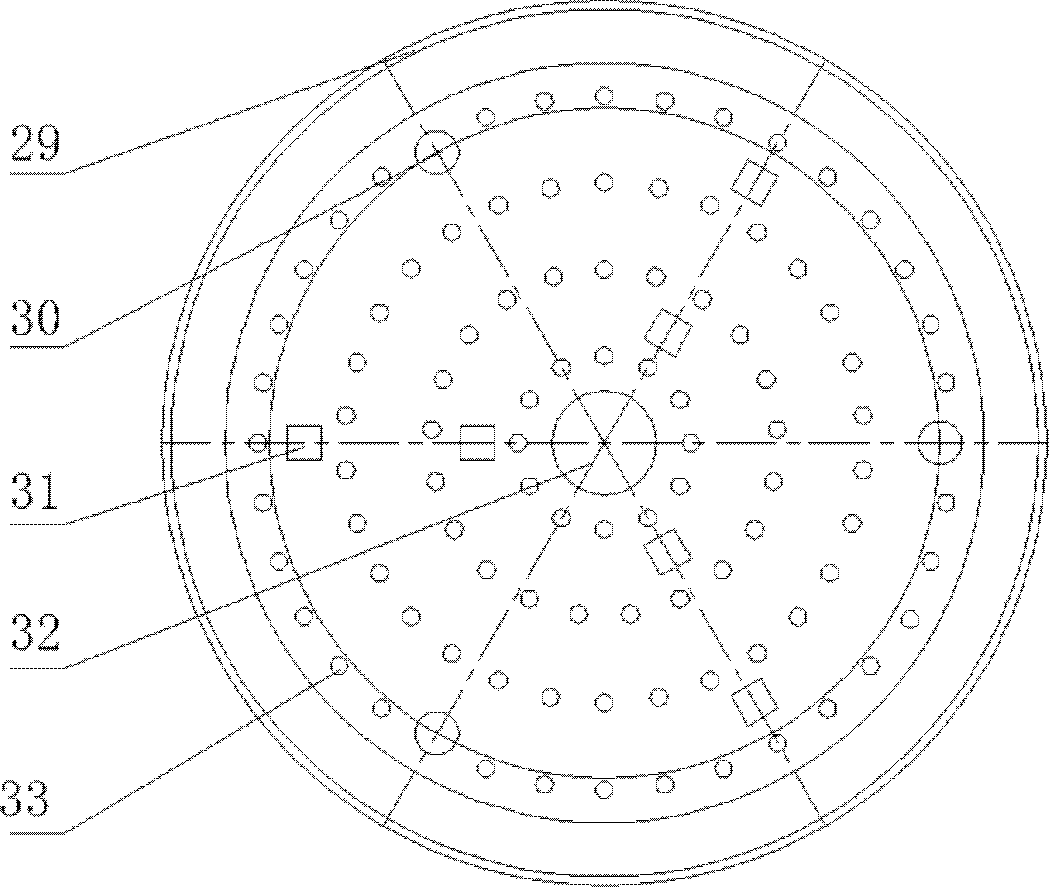

[0049] 1. Open the model box (3), remove the mining simulation movable plate (27), fix the pressure sensor (21) on the base (21), and install the pore water pressure sensor (7) nearby, and install the water-sand separation Sieve (11), put sand filter net (12), connect the signal line (18), lift the mining simulation hydraulic cylinder, install the sand stopper (15), and proceed to the next step after detecting that the signal connection and mechanical device are normal, otherwise Return to step 1.

[0050] 2. Install the sand breach simulation board (10), align the sand breach mouth (13) and the sand stopper (15), seal the sand breach simulation board (10) and the mining simulation top (bottom) board ( 9) Temporarily seal the gap between the side walls of the model box (3), and test the sealing performance with water injection to ensure reliable sealing. Open the hydraulic system to control the min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com