Sand-bag and steel sheet pile combined cofferdam for hard formation and construction method of cofferdam

A technology combining cofferdams and construction methods, applied in sheet pile walls, infrastructure engineering, buildings, etc., can solve the problems of easy seepage, insufficient draft depth, and difficulty in achieving water-stopping effect, and achieve good water-stopping performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

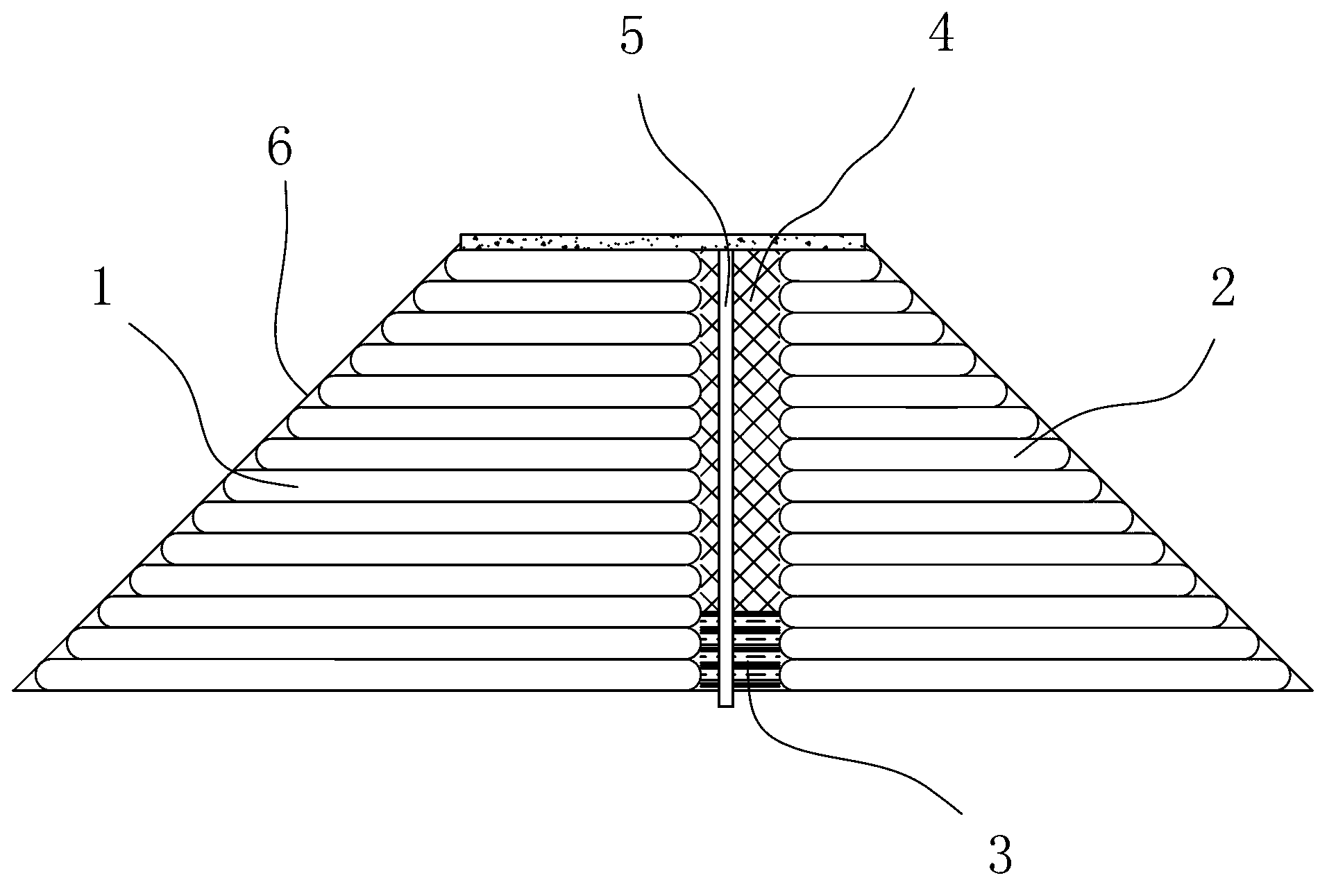

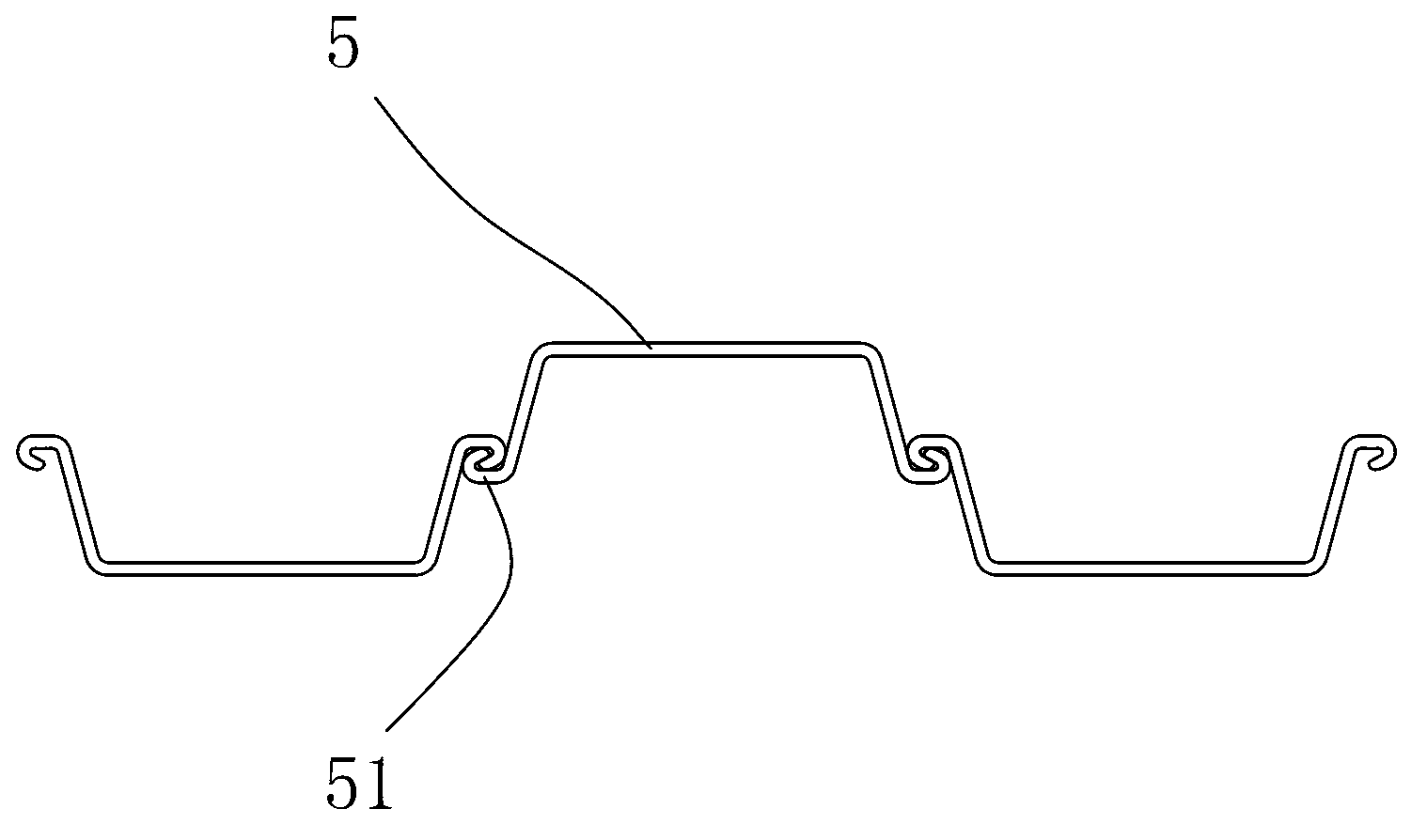

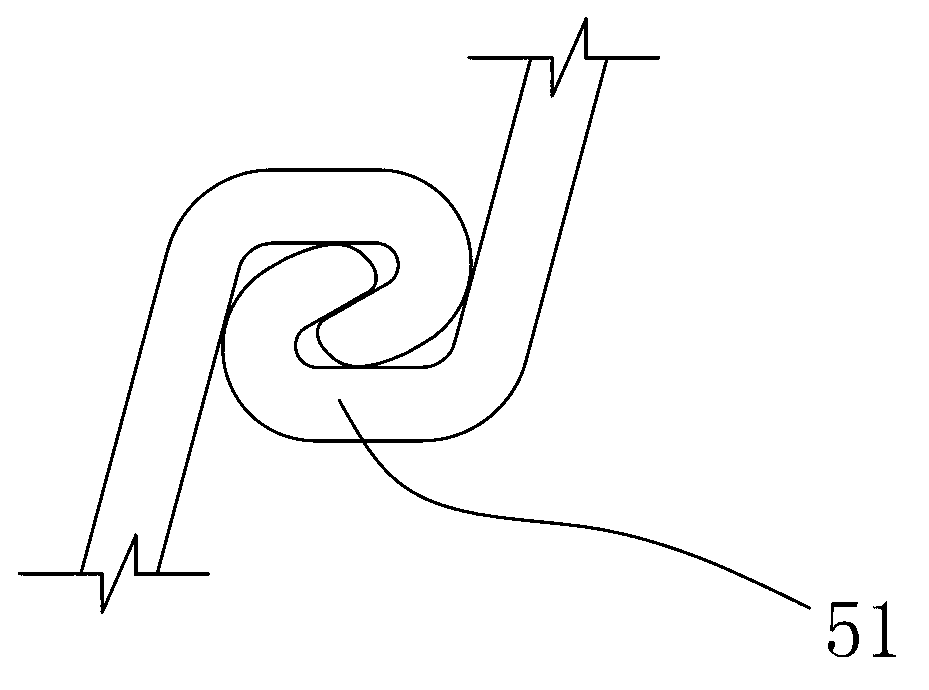

[0022] refer to Figure 1 to Figure 3 , the present invention is a mold bag sand and steel sheet pile combined cofferdam for hard ground, comprising an inner weir body 1 and an outer weir body 2 arranged on the hard ground, between the inner weir body 1 and the outer weir body 2 The bottom of the gap is provided with a clay layer 3, and the gap between the inner weir body 1 and the outer weir body 2 is filled with a sandy soil layer 4, and there are also several inter-connected weir bodies between the inner weir body 1 and the outer weir body 2. A single row of steel sheet piles 5, the steel sheet piles 5 go through the sand layer 4 and the clay layer 3 and go deep into the hard ground.

[0023] By setting a clay layer 3 at the bottom of the gap between the inner weir body 1 and the outer weir body 2, and setting a sandy soil layer 4 on it, the steel sheet pile 5 penetrates the sandy soil layer 4 and the clay layer 3 deep into the hard ground To form the water-stop core wall,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com