Microorganism cause concrete or concrete, producing method and application thereof

A microbial cement and production method technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of difficult to achieve high-quality ancient building protection and restoration, failure to achieve strength and size, and organic polymer weather resistance sex is difficult to guarantee and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Preparation of Microbiologically Originated Cement

[0071] (1) Weigh 15.75g of tris, dilute to 1L with deionized water, titrate to pH=8 with 1M HCl, add 20g of yeast powder, (NH 4 ) 2 SO 4 10g, stir evenly to obtain culture medium;

[0072] (2) Sporosarcina pasteurii seed strain ATCC11859 (purchased from the American Culture Collection Center) was resuscitated and divided into plastic ampoules, and one tube (1.8ml) was inoculated into 250ml prepared in step (1). In the culture medium, shake culture at 30°C and 150rpm for 40h to obtain the bacterial solution;

[0073] (3) Mix 180g of urea, 200g of calcium chloride and 300g of calcium nitrate tetrahydrate, add water to 1L, and stir until fully dissolved to obtain a compound solution;

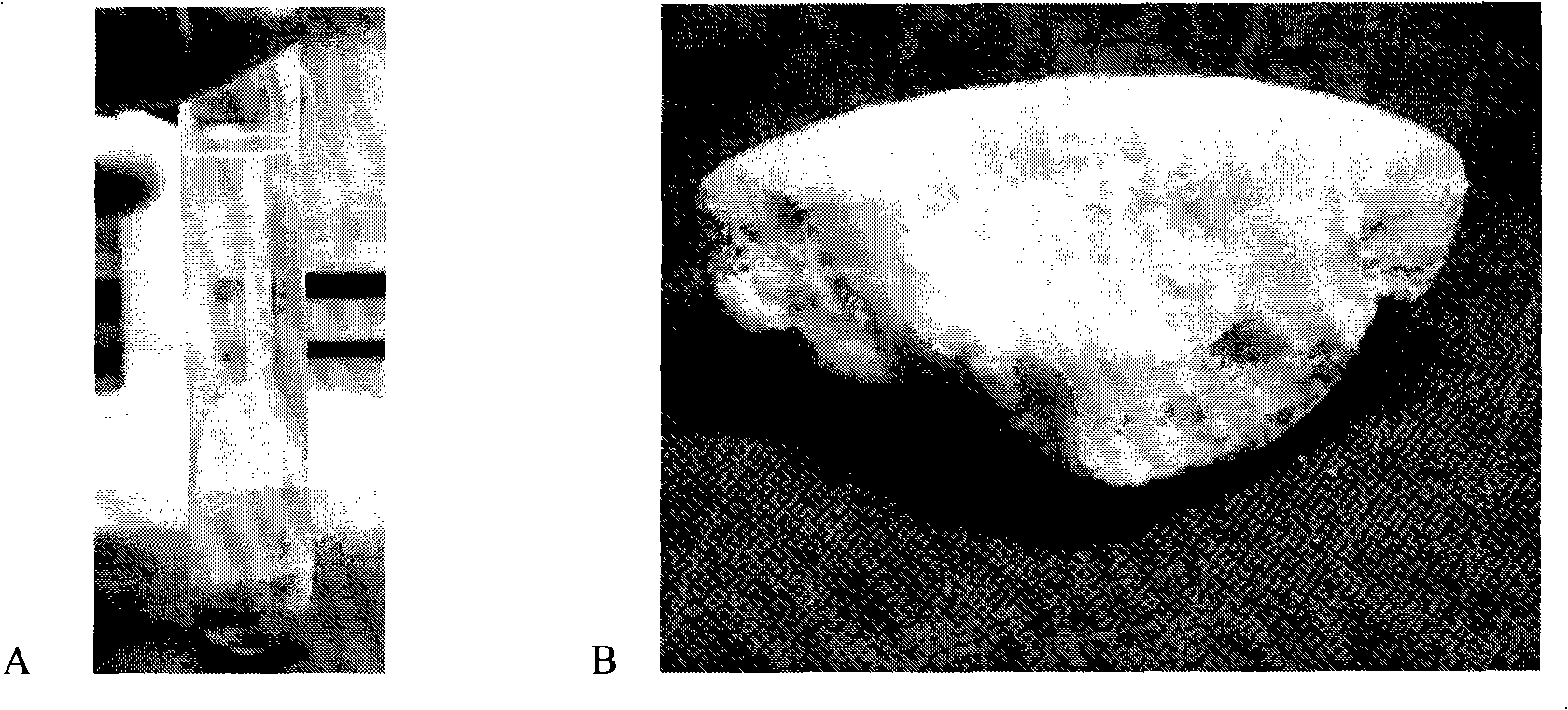

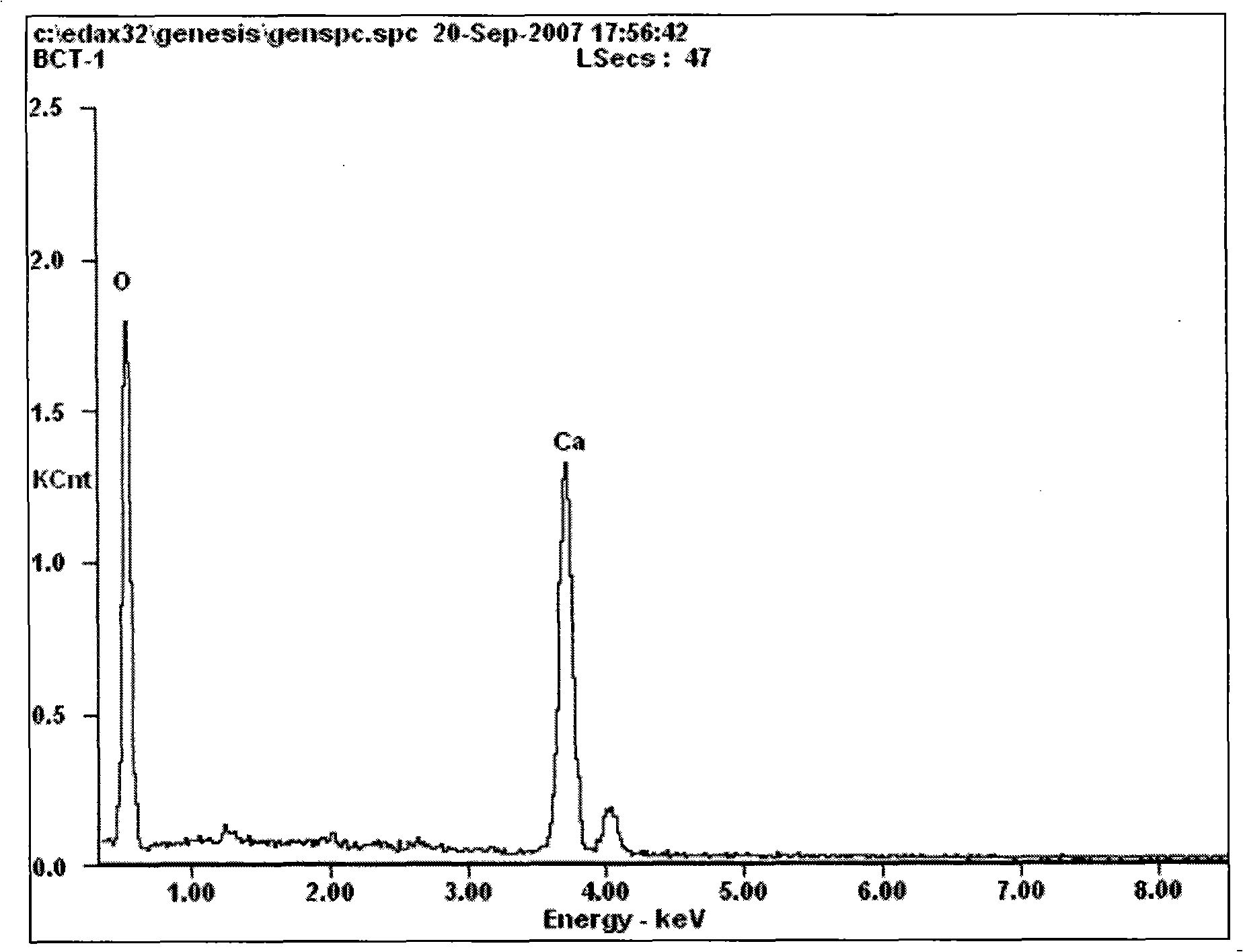

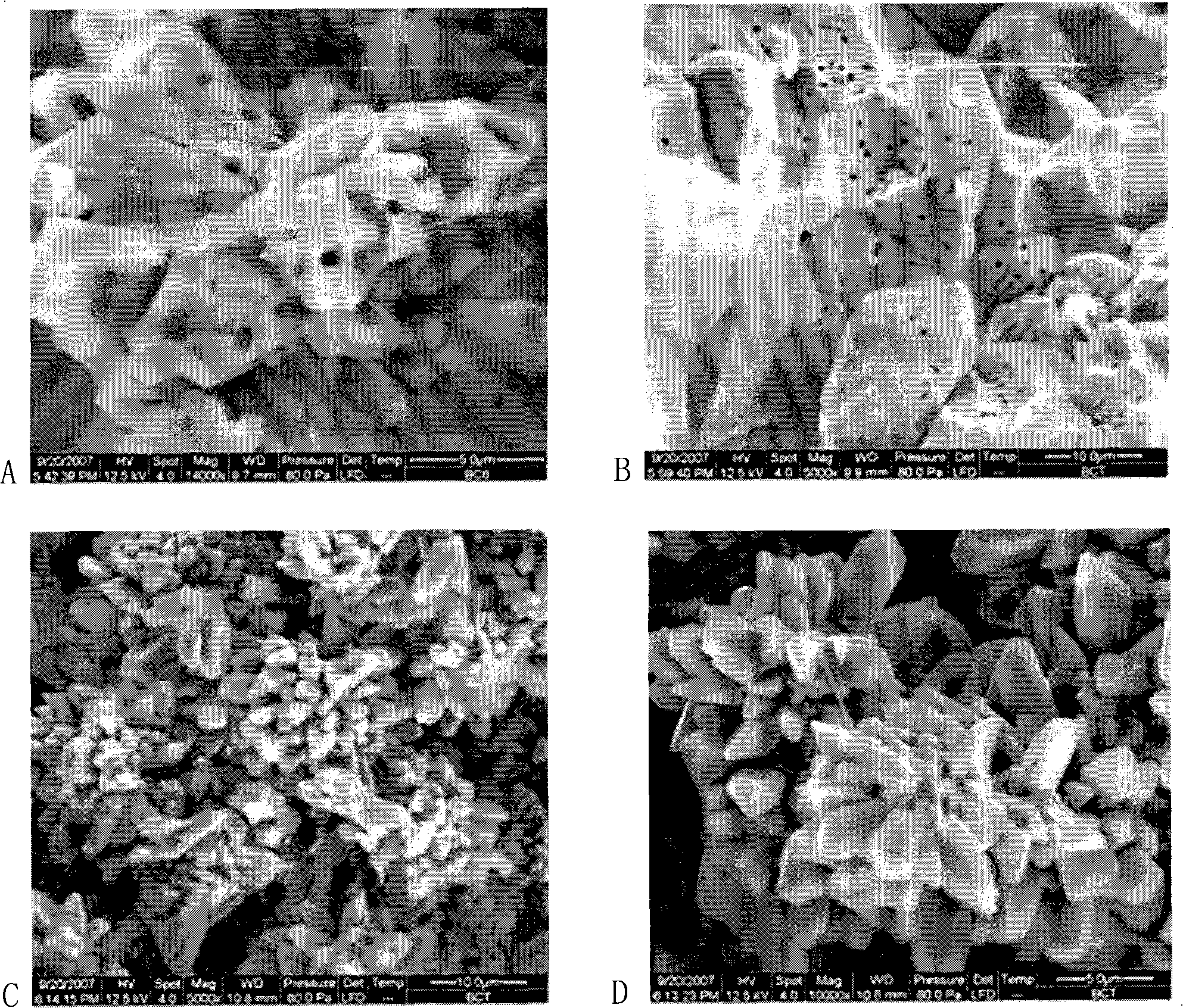

[0074] (4) Titrate the bacterial solution cultivated in step (2) to pH=7 with 1M HCl, take 30ml of bacterial solution and 20ml of compounding solution, mix evenly, and let stand at 28°C for 48h, the result (see figure 1 ) The cementit...

Embodiment 2

[0078] Preparation of Concrete of Microbial Origin

[0079] Titrate the bacterial solution cultured in step (2) of Example 1 to pH=7 with 1M HCl, take 3ml into a test tube, then take 3ml of the compound solution prepared in Example 1 into the test tube, mix well, and react at 28°C 1h, then add 3ml of sand (particle size 0.63-1.25mm), let stand at 28°C for 48h, the result (see Figure 4 ) At the bottom of the test tube, it can be seen that the sand particles in contact with the microbial cement are bonded by the microbial cement, and the bonded product is the microbial concrete.

Embodiment 3

[0081] Preparation of Concrete of Microbial Origin

[0082] Add 10ml of sand grains (particle size 1.25-2.5mm) in a 150ml container, titrate the bacterial solution prepared in Example 1 to pH=7 with 1M HCl, take 30ml into the container, and then take 40ml of the compounding solution prepared in Example 1 into the container , mixed evenly, and stood at 28°C for 48 hours. As a result, there was microbial cement at the bottom of the container (on top of the sand grains), and a layer of sand grains in contact with the microbial cement was bonded by the microbial cement. The product of microbial origin is "concrete".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com