Filter medium, preparation method thereof, filter element and water purification device

A filter medium and water removal technology, applied in the direction of filtration separation, separation method, gravity filter, etc., to achieve the effect of low cost, simple method and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

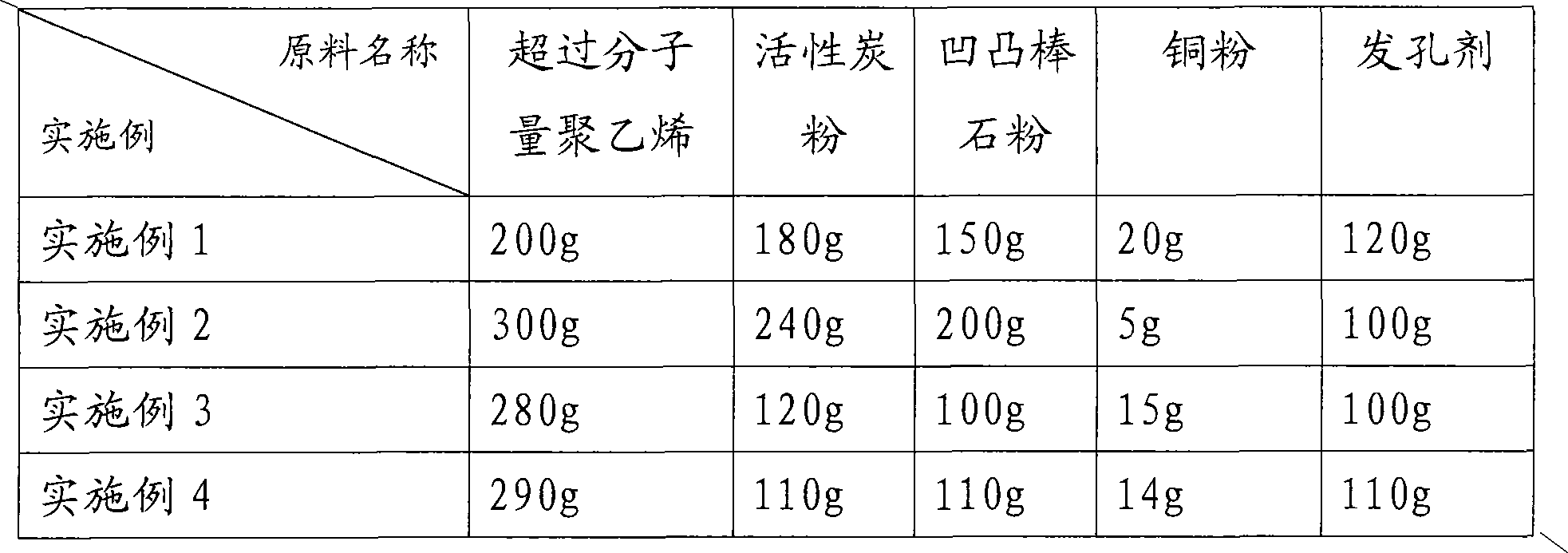

Embodiment 1

[0028] The specific steps of this embodiment include the following steps:

[0029] (1) Weigh 200 g of ultra-high molecular weight polyethylene powder. The ultra-high molecular weight polyethylene is the M-III product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, with a molecular weight of 3.5 million and a particle size of 89 to 104 UHMWPE powder of 89-104 microns can be obtained by screening with 140-mesh and 170-mesh sieves;

[0030] (2) Take medical active carbon powder 180g, the particle diameter of described medical active carbon is 74~89 microns, utilize 170 order and 200 order sieves to screen and can obtain the medical active carbon powder of 74~89 microns;

[0031] (3) Weighing 150 g of attapulgite powder, the particle size of the attapulgite powder is 74 to 89 microns, and the attapulgite powder of 74 to 89 microns can be obtained by screening with 170 mesh and 200 mesh sieves;

[0032] (4) take copper powder 20g, the particle diameter of descri...

Embodiment 2

[0038] The specific steps of this embodiment include the following steps:

[0039] (1) Weigh 300 g of ultra-high molecular weight polyethylene powder. The ultra-high molecular weight polyethylene is the M-II product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. UHMWPE powder of 89-104 microns can be obtained by screening with 140-mesh and 170-mesh sieves;

[0040] (2) Take medical active carbon powder 240g, the particle diameter of described medical active carbon is 74~89 microns, utilize 170 order and 200 order sieves to screen and can obtain the medical active carbon powder of 74~89 microns;

[0041] (3) Weigh 200 g of attapulgite powder, the particle size of which is 74 to 89 microns, and use 170 mesh and 200 mesh sieves to screen to obtain attapulgite powder of 74 to 89 microns;

[0042] (4) take copper powder 5g, the particle diameter of described copper powder is below 74 microns, utilizes 200 order sieves to screen and promptly can obtain the copper powder ...

Embodiment 3

[0048] The specific steps of this embodiment include the following steps:

[0049] (1) Weigh 280 g of ultra-high molecular weight polyethylene powder. The ultra-high molecular weight polyethylene is the M-II product of the No. 2 Auxiliary Factory of Beijing Dongfang Petrochemical Co., Ltd., with a molecular weight of 2.5 million and a particle size of 89 to 104 UHMWPE powder of 89-104 microns can be obtained by screening with 140-mesh and 170-mesh sieves;

[0050] (2) Take medical active carbon powder 120g, the particle diameter of described medical active carbon is 74~89 microns, utilize 170 order and 200 order sieves to screen and can obtain the medical active carbon powder of 74~89 microns;

[0051] (3) Weighing 100 g of attapulgite powder, the particle size of the attapulgite powder is 74 to 89 microns, and the attapulgite powder of 74 to 89 microns can be obtained by screening with 170 mesh and 200 mesh sieves;

[0052] (4) take copper powder 15g, the particle diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com