Underground and overground continuous construction method for major-diameter high flat bed pile in sandy soil stratum

A high-capped pile and construction method technology, applied in the field of building foundation engineering, can solve problems such as the instability of the casing, the existence of safety hazards, and uneven stress distribution, and achieve the goals of reasonable design of construction steps, easy pile quality, and expanded adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

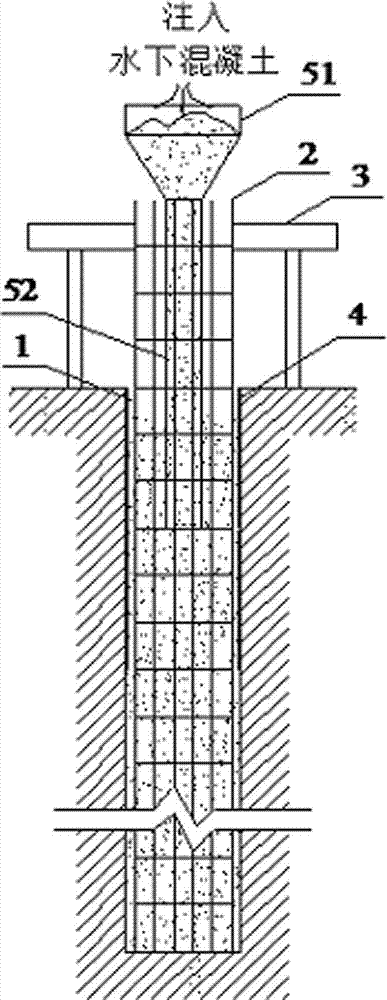

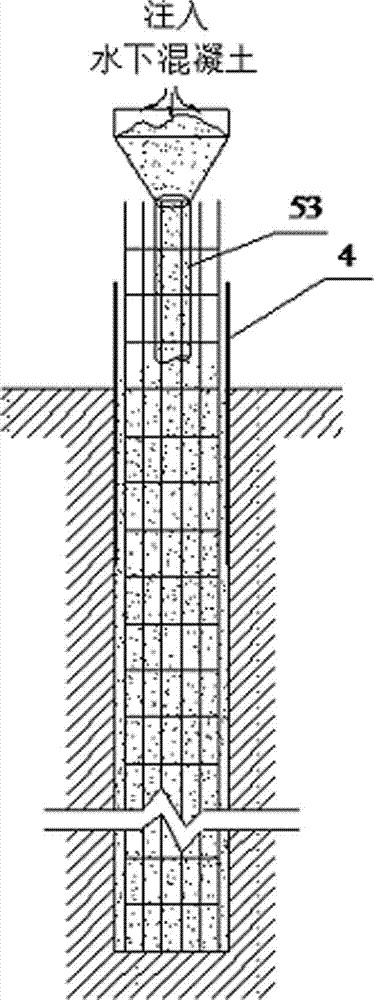

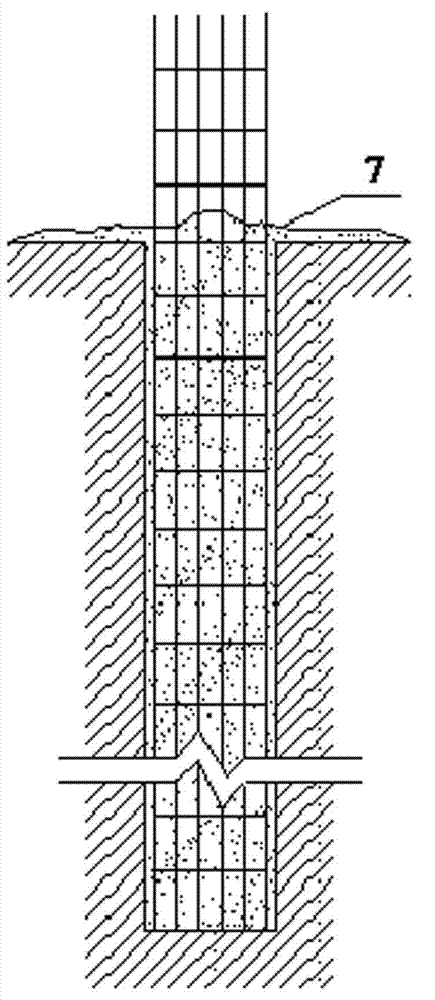

[0026] according to Figure 1 to Figure 6 Shown:

[0027] A method for continuous construction on large-diameter high-capped piles in sandy soil stratum, comprising the following steps:

[0028] Ⅰ) Use a rotary drilling rig to dig a hole at a predetermined position, bury a 3m-10m steel casing 4 according to the stratum conditions, drill to the designed hole depth, clear the hole, and form a drill hole 1, and place a reinforcement cage 2 through the pre-construction platform 3 and The grouting conduit 52, after the secondary hole clearing, begins to pour the underwater concrete, and suspends the pouring until it is about 50cm-100cm below the ground level;

[0029] Ⅱ) Remove the upper pre-construction platform 3 and the grouting conduit 52, slowly pull up the steel casing 4, so that the top of the steel casing 4 is 60cm-100cm above the ground, and continue pouring with the grouting pump or the rubber hose 53 at the end of the grouting funnel 51 For underwater concrete, stop pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com