High-performance sand-soil consolidation material, as well as preparation method and using method thereof

A kind of consolidation material and high-performance technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of polluting the environment, occupying land, etc., achieve high early strength, reduce project cost, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Accurately weigh 8.5 parts by weight of Portland cement clinker, 6 parts by weight of anhydrite, 10 parts by weight of quicklime, Na 2 SO 4 0.2 parts by weight, 4 parts by weight of calcium chloride, 5 parts by weight of fly ash, 5 parts by weight of magnesium chloride, 70 parts by weight of blast furnace quenched slag fine powder, mixed and ground to a specific surface area of 400-420m 2 / kg. The high-performance sand-soil consolidation material of the present invention is obtained.

Embodiment 2~ Embodiment 6

[0047] According to the preparation method of Example 1, according to the formula of Table 1, prepare the high-performance sandy soil consolidation material of the present invention

[0048] Table 1

[0049] Raw materials and technical indicators Example 2 Example 3 Example 4 Example 5 Example 6 Kraft cement clinker 13.5 Ferro-aluminate cement clinker 20 5 Fluoroaluminate cement clinker 30 High aluminate cement clinker 40 Portland cement clinker 8.5 Phosphogypsum 5 6

[0050] Anhydrite 3 Power plant desulfurization recovery gypsum 4 5 Sodium silicate 5 4 quicklime 10 8 sodium hydroxide 6 Li 2 o 3 6 2 KC 5 ZnCl 2 4 Na 3 PO 4 0.5 Triethanolamine ...

Embodiment 7~ Embodiment 12

[0052] The high-performance sandy-soil consolidation material of the present invention prepared in embodiment 1~embodiment 6 application experimental results are listed in table 2

[0053] Table 2

[0054]

[0055] The present invention discloses the application test results of the high-performance sandy soil consolidation material of the present invention as Table 3 to Table 11 below.

[0056] table 3:

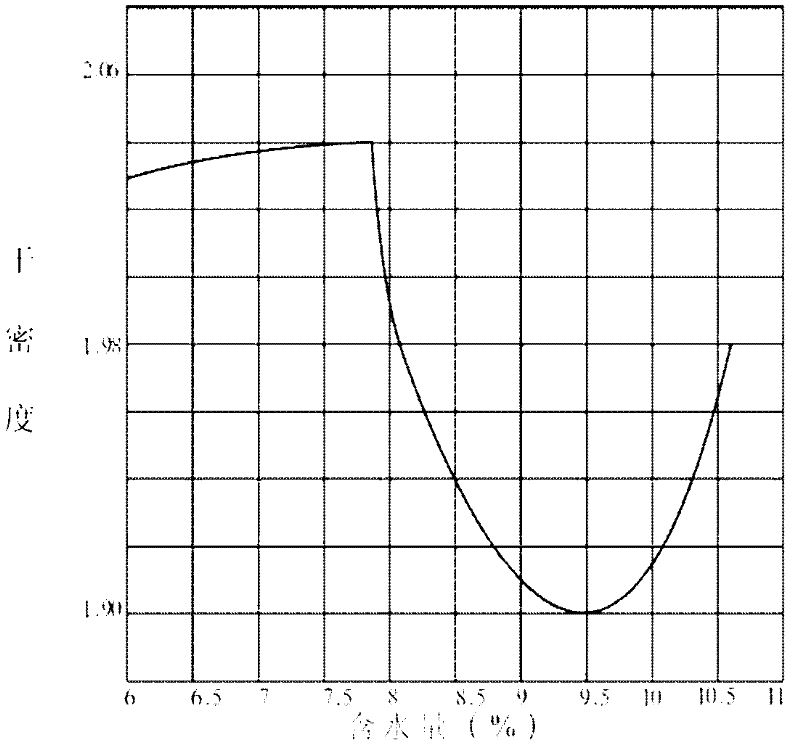

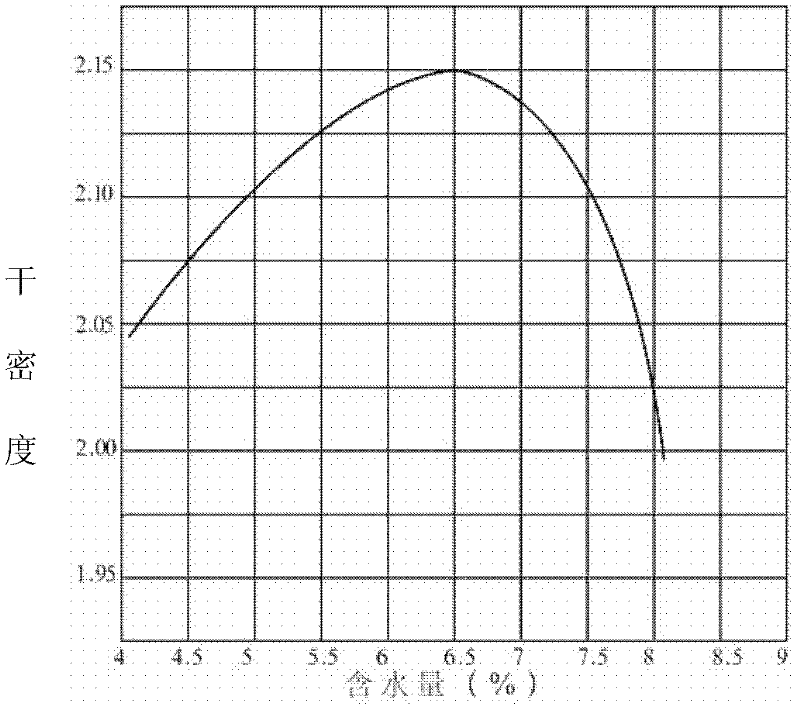

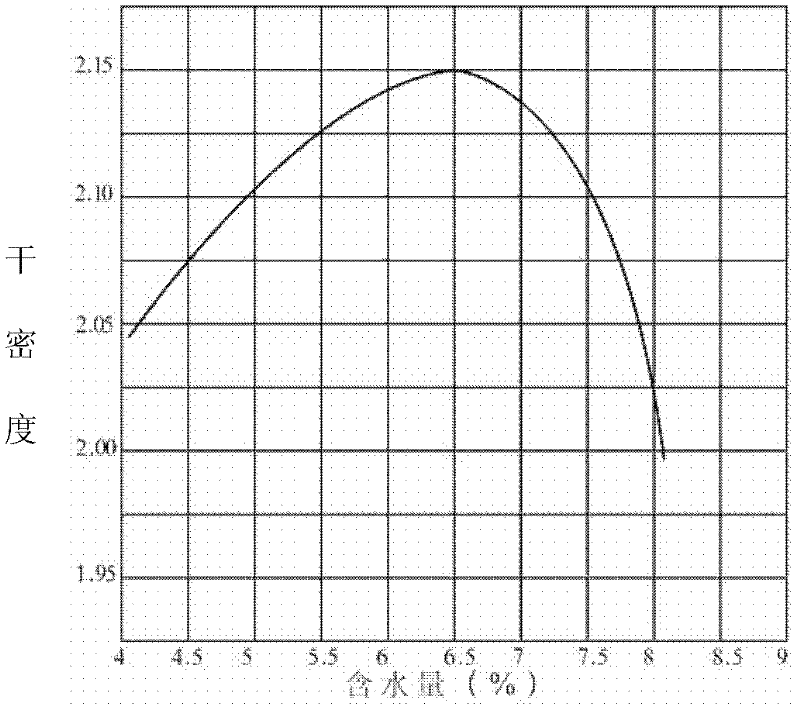

[0057] Standard compaction test report

[0058] No.: SB-2011-13-0029

[0059]

[0060]

[0061] Table 4

[0062] Test report on unconfined compressive strength of stabilized soil

[0063] No.: SB-2011-13-0030

[0064]

[0065]

[0066] table 5

[0067] Standard compaction test report

[0068] No.: SB-2011-13-0031

[0069]

[0070]

[0071] Table 6

[0072] Test report on unconfined compressive strength of stabilized soil

[0073] Report No.: SB-2011-13-0032

[0074]

[0075]

[0076] Table 7

[0077] Cement Comparison Table

[0078]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com