Drilling-hole press-filling-concrete-pulp agitation base-enlarging method and apparatus

A technology for pouring concrete and mixing device, which is applied to drilling tools, drilling equipment, earthwork drilling, etc., can solve problems such as the influence of mixing and bottom expansion, unsatisfactory failure rate, and easy damage, and achieves simple structure, fast construction speed, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

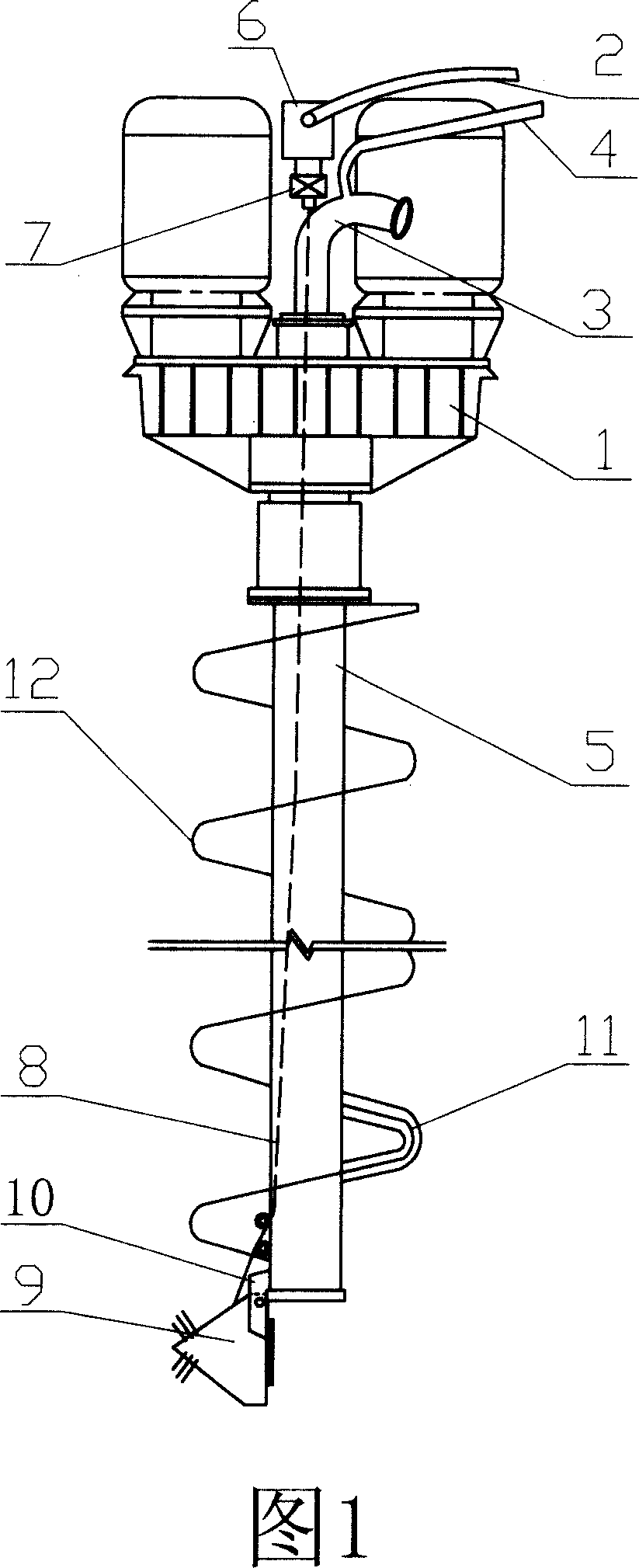

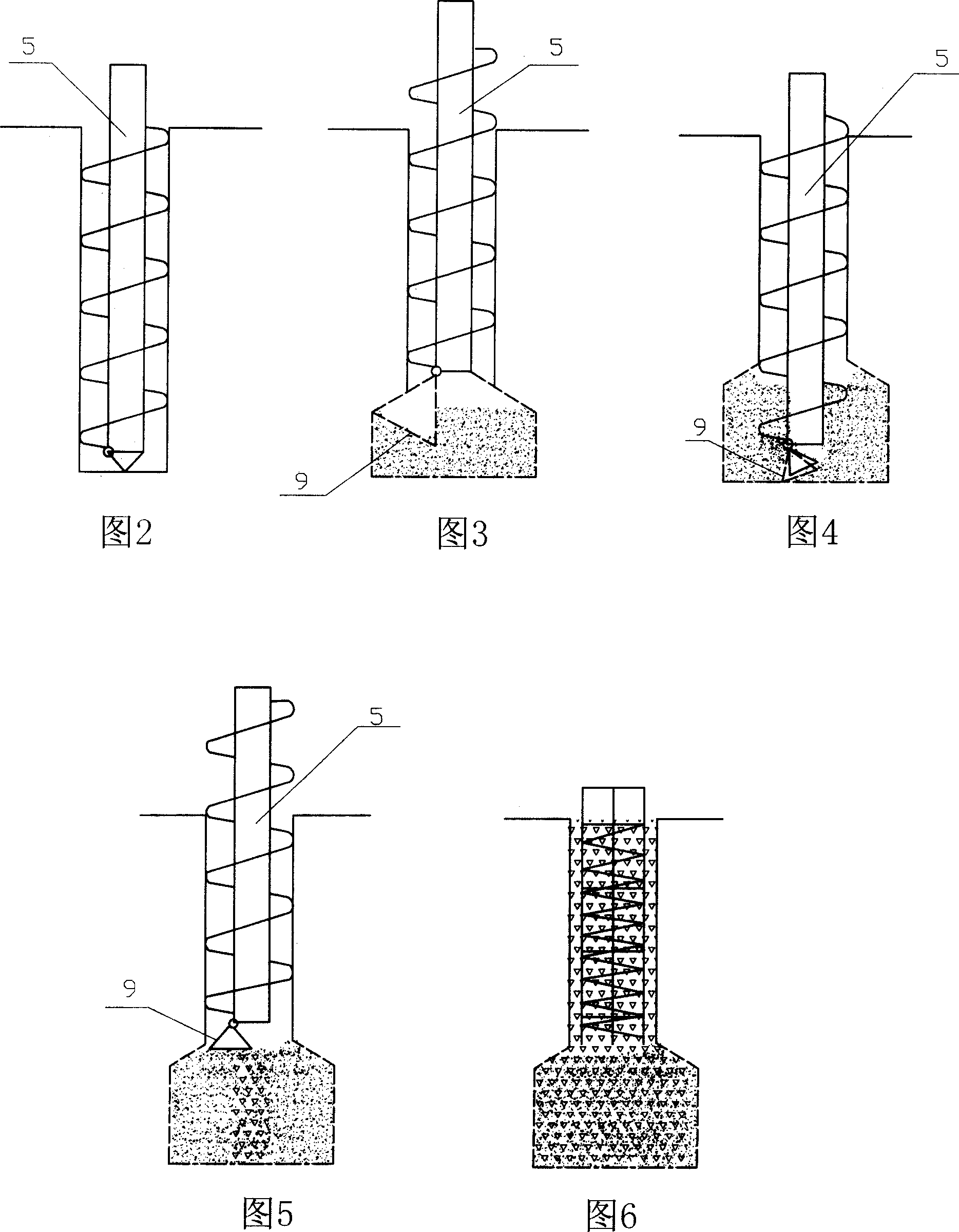

[0029] Bore hole pressure grouting concrete grouting mixing bottom expansion method, when the drilling rig is drilling, inject cement slurry into the core tube of the drill pipe through the grouting pipeline installed on the elbow, and start the drill set on the upper part of the power head when drilling to the design depth The hydraulic cylinder pulls the wire rope through the anti-twist rotary head at the lower end of the piston rod of the hydraulic cylinder, and drives the flip-type drill bit to turn over. After the turned diameter exceeds the diameter of the drill pipe and meets the design requirements, it is lifted while rotating and expanding the bottom. After the sandy soil layer and the cement slurry are stirred and expanded to reach the design height, the hydraulic cylinder retracts and turns the drill bit to stop stirring and expands the bottom, and finally the concrete is poured while lifting the drill to form a pile.

Embodiment 2

[0031] In the method for drilling, pressurized concrete, grouting, stirring and expanding the bottom described in Example 1, when stirring and expanding the bottom, concrete is injected separately for stirring and expanding the bottom to form a pile.

Embodiment 3

[0033] In the borehole pressure grouting concrete grouting method for bottom expansion described in embodiment 1 or 2, when stirring and bottom expansion, cement slurry is injected separately for stirring and bottom expansion to form a pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com