Auxiliary pile sinking device for prefabricated hollow pile

A hollow pile and pile driving technology, applied in sheet pile wall, construction, infrastructure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the purpose, structure and function of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings.

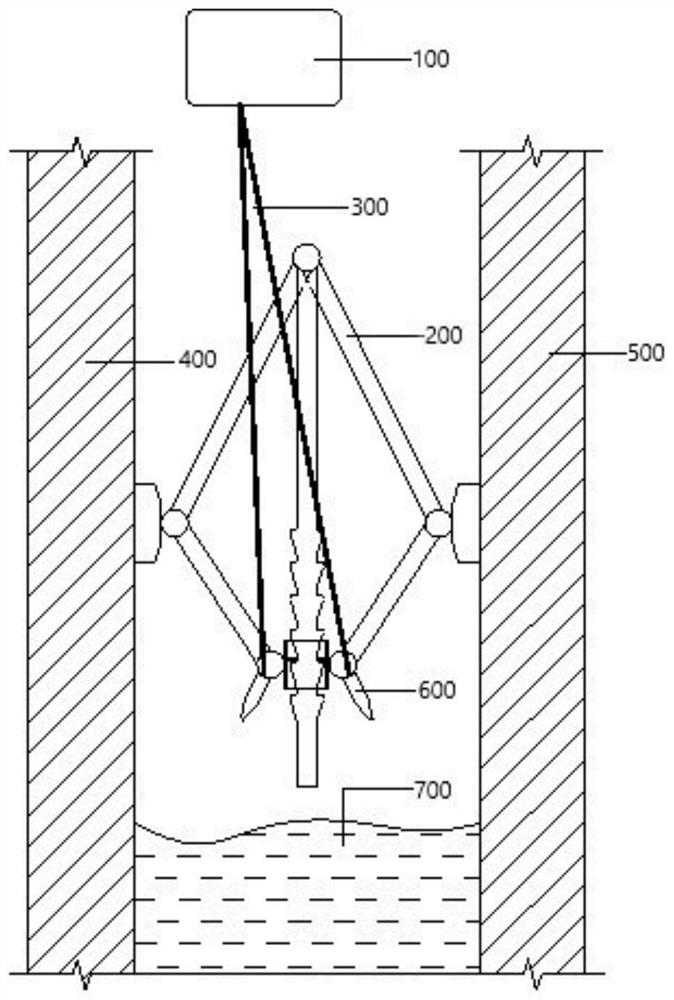

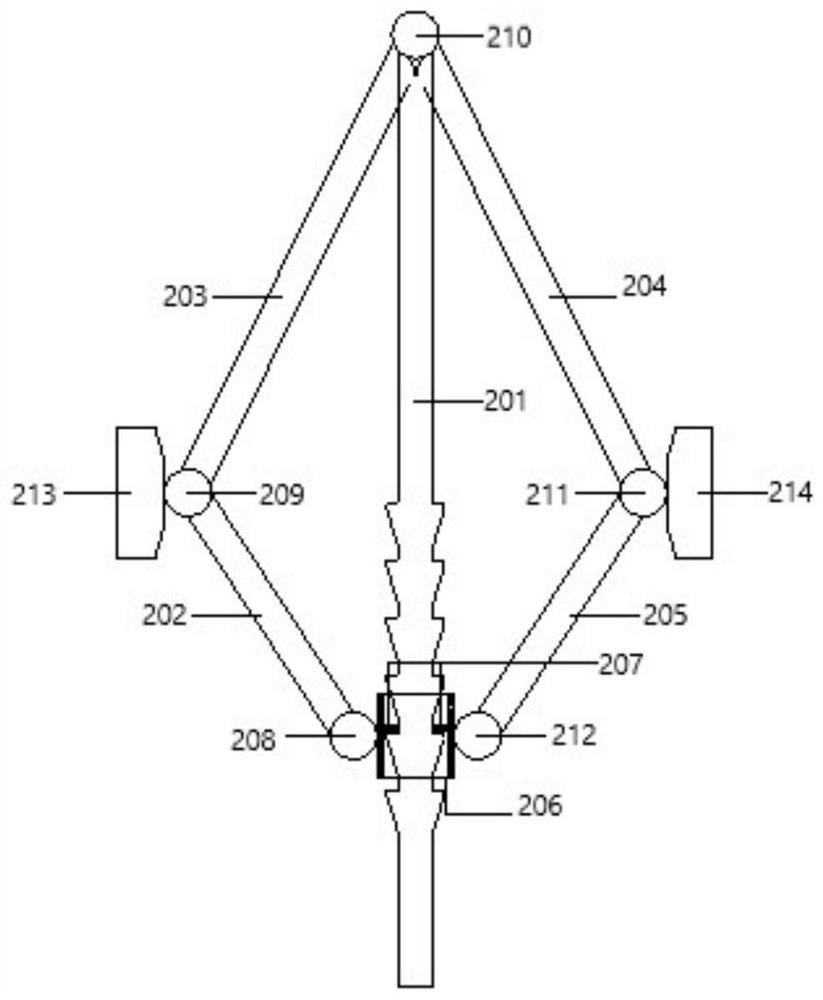

[0024] Such as figure 1 As shown, an auxiliary pile sinking device for prefabricated hollow piles of the present invention is composed of a booster pump 100 , a fixing frame 200 , a water pipe 300 and a nozzle 600 . The fixed frame 200 is installed on the inner wall of the right hollow pile 500 and the left hollow pile 400 near the bottom of the pile. The fixed frame 200 is equipped with a nozzle 600 , and the nozzle 600 and the booster pump 100 are connected through the water pipe 300 .

[0025] When in use, the fixing frame 200 is first installed on the prefabricated hollow pile (5), and after the fixing is completed, the static pressure pile is started. When encountering a soil layer with high resistance such as hard clay and sandy soil, start the booster pump 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com