Low-clinker high-impermeability field floor hardening material based on dry process desulfurized fly ash

A technology for dry desulfurization ash and sintered desulfurization ash is applied in the field of inorganic non-metallic materials, less clinker and high impermeability type field hardening materials, and can solve the rising cost of commercial concrete, the low comprehensive utilization rate of construction and industrial solid waste, Environmental impact and other problems, to achieve the effect of large solid waste consumption, excellent impermeability and good impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

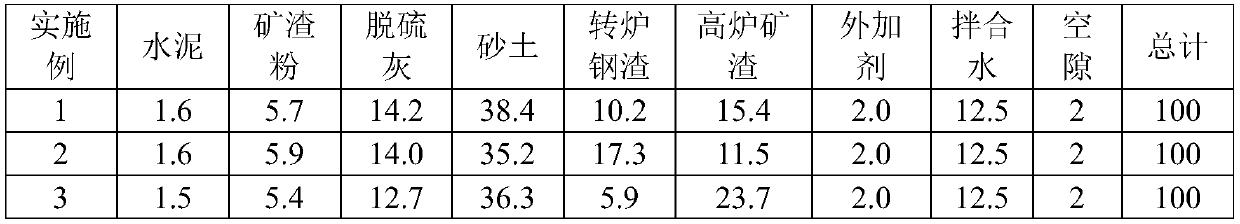

[0053] Due to the large difference in the apparent density of various raw material components, according to the volume ratio and the apparent density of each component, the mass of various raw material components required for a unit volume of field hardening material can be prepared, so the volume fraction is used For the description, the following is the content of each raw material component when preparing the low-clinker and high-impermeability field hardening material based on dry desulfurization ash in Examples 1-3, as shown in Table 3.

[0054] table 3

[0055]

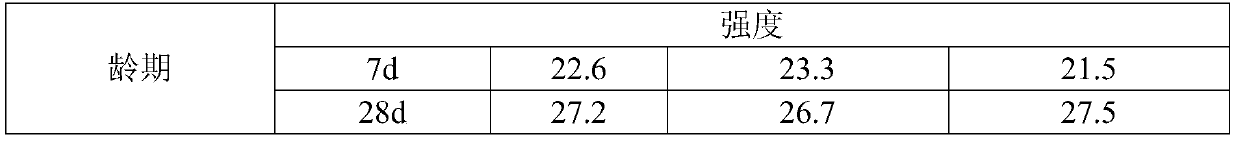

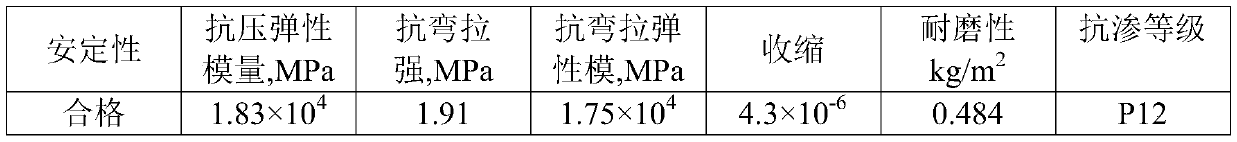

[0056] After testing, the 7d compressive strength, 28d compressive strength and 28d flexural tensile strength of the low-clinker and high-impermeability type field hardening materials based on dry desulfurization ash obtained in Examples 1-3 reached the highest respectively. The main reasons are:

[0057] (1) With a small amount of cement and sintered desulfurization ash as the cementing material, and constru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com