Method and system for preparing sulfoaluminate cement from all solid wastes pretreated by aluminum ash

A sulphoaluminate cement and pretreatment technology, which is applied in building materials technology, comprehensive utilization of bulk industrial solid waste resources, environmental protection and treatment, and aluminum processing fields, can solve problems such as long-term operation, condenser blockage, and easy knot of rotary kiln Circle and other issues to achieve the effect of increasing energy utilization and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

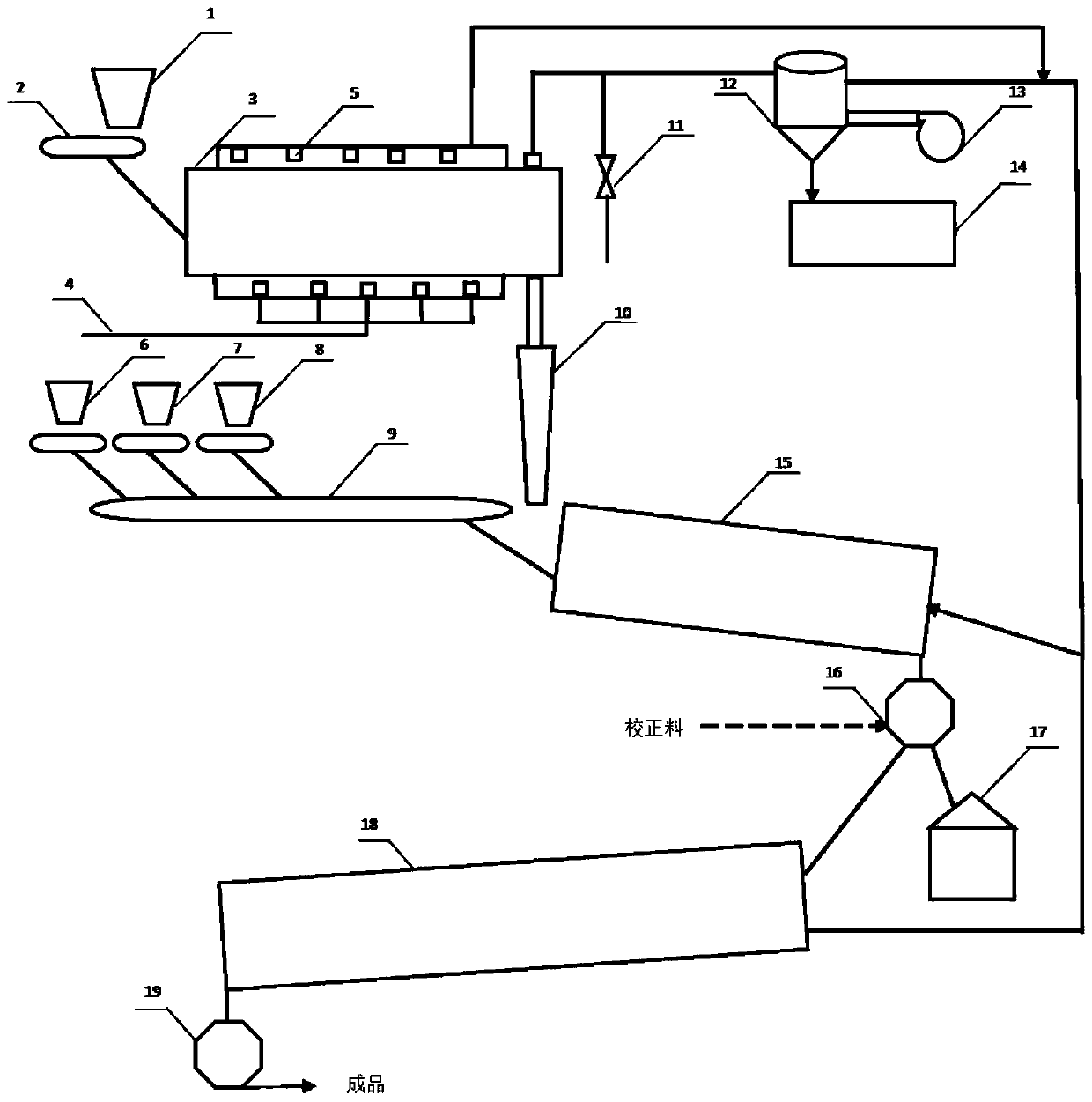

[0057] In order to realize the preparation of sulphoaluminate cement from the above-mentioned aluminum ash pretreatment of all solid waste, the third embodiment of the present invention provides a method for realizing the above-mentioned aluminum ash pretreatment of all solid waste to prepare sulphoaluminate cement System, including indirect rotary drum heating furnace, cyclone condenser, dryer, raw material pulverizer, rotary kiln, the inlet of indirect rotary drum heating furnace is set to connect aluminum ash source, the solid phase outlet of indirect rotary drum heating furnace is connected The material inlet of the dryer, the gas phase outlet of the indirect rotary drum heating furnace is connected to the inlet of the cyclone condenser, the gas phase outlet of the cyclone condenser is connected to the heat exchange gas inlet of the dryer, and the material inlet of the dryer is also set to be used to connect the red mud source , desulfurization gypsum source, calcium carbid...

Embodiment 1

[0066] A system for preparing sulphoaluminate cement from all solid waste pretreated with aluminum ash, such as figure 1 As shown, hopper 1, automatic weighing scale 2, indirect drum heating furnace 3, burner nozzle 5, red mud storage bin 6, desulfurized gypsum storage bin 7, carbide slag storage bin 8, belt conveyor 9, feeding pipe Road 10, air extractor 11, cyclone condenser 12, cooling fan 13, salt storage bin 14, rotary drying cylinder 15, raw material grinding machine 16, dry raw material bin 17, rotary kiln 18, material grinding machine 19.

[0067]The aluminum ash is first fed into the automatic weighing scale 2 through the hopper 1, and sent into the indirect rotary drum heating furnace 3 through the belt conveyor, and the natural gas 4 is heated to the indirect rotary drum heating furnace 3 through the burner nozzle 5 to realize the indirect transfer The aluminum ash in the drum heating furnace 3 is denitrified and desalted by high-temperature calcination, and the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com