Method for preparing sulphoaluminate cement clinker by using red mud and phosphogypsum

A technology of sulfoaluminate cement and phosphogypsum, which is applied in the field of cement clinker production, can solve the problems of unsatisfactory product quality, unsatisfactory sulfoaluminate cement clinker cannot meet the needs of actual use, and the amount of phosphogypsum is small, and the like, Achieve the effect of low production cost, good product quality and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

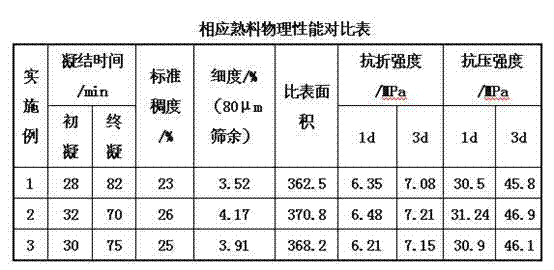

Embodiment 1

[0010] Example 1: Red mud (sintered red mud), phosphogypsum, bauxite, and limestone are used as raw materials for production, and each raw material is dried and ground to obtain raw meal below 180 mesh, calculated by weight , respectively take 10 parts of red mud, 16.5 parts of phosphogypsum, 33 parts of bauxite, and 40.5 parts of limestone in each raw meal, mix the raw materials together and put them into the rotary kiln, and heat them at a temperature of 1250 ° C to 1350 ° C After sintering for 15 to 50 minutes, the kiln is quickly released, and the sintered raw materials are quenched in the air to obtain the finished product of sulphoaluminate cement clinker; Mud; in order to achieve better product quality, when using a rotary kiln to calcine raw meal, a conventional desulfurization device can be installed in the traditional way at the kiln tail of the conventional rotary kiln, which can better treat the raw meal. The red mud is dealkalized.

Embodiment 2

[0011] Example 2: Red mud (Bayer process red mud), phosphogypsum, bauxite, and limestone are used as raw materials for production, and each raw material is dried and ground to obtain a raw meal below 180 mesh, calculated by weight , respectively take 14.22 parts of red mud, 18.21 parts of phosphogypsum, 29.15 parts of bauxite, and 38.42 parts of limestone in each raw meal. After sintering for 30 to 50 minutes, the kiln is quickly released, and the finished product of sulphoaluminate cement clinker can be obtained after rapid cooling; the red mud used is the Bayer process red mud in the prior art; in order to achieve better product quality When using a rotary kiln to calcine the raw meal, a conventional desulfurization device can be installed at the kiln tail of the conventional rotary kiln in a traditional way, so that the red mud in the raw meal can be dealkalized better.

Embodiment 3

[0012] Example 3: Using red mud (a mixture of sintering red mud and Bayer red mud), phosphogypsum, bauxite, and limestone as production raw materials, each raw material was dried and ground to obtain 180 For the raw meal below the order, calculated by weight, take 14 parts of red mud, 15 parts of phosphogypsum, 35 parts of bauxite, and 42 parts of limestone in each raw meal, mix each raw meal together and put it into the rotary kiln , and sintered at a temperature of 1250°C to 1350°C for 15 to 50 minutes, and then quickly exit the kiln, so that the sintered raw materials can be rapidly cooled in the air, and the finished sulphoaluminate cement clinker can be obtained; the red used in it The mud is a red mud mixture obtained by mixing sintering red mud and Bayer red mud in the prior art. In the red mud mixture, the ratio is calculated in parts by weight: 20-60 parts of sintering red mud, 20-60 parts of Bayer red mud 30 to 50 parts of red mud. In this example, the same amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com