Method for producing alumina by using pulverized fuel ash

A technology of alumina and fly ash, which is applied in the field of preparing alumina by using fly ash, can solve the problems of equipment and pipeline corrosion, secondary pollution, high cost, etc., and achieve the effect of easy equipment, easy use, and industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The composition of raw fly ash is: Al 2 o 3 : 41%, SiO 2 : 48%, Fe 2 o 3 : 3.3%, CaO: 3.3%, TiO 2 : 1.3%, MgO: 0.2%. The composition of the raw fly ash can also use other components, which cannot be used to limit the protection scope of the present invention.

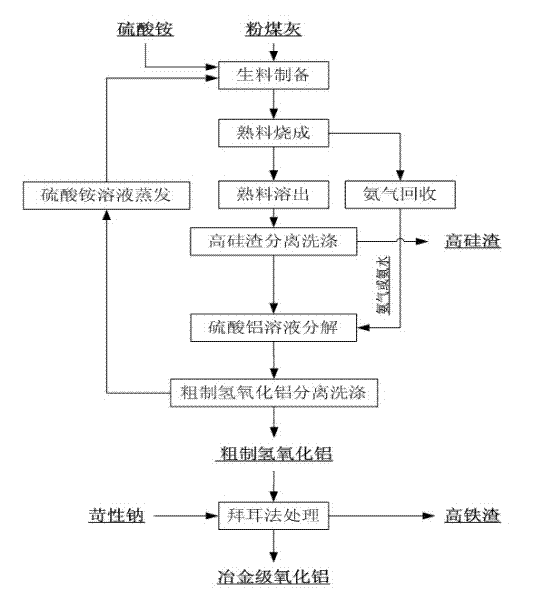

[0022] Take 1000g of fly ash with the above composition, mix the fly ash with ammonium sulfate solution and wet grind to obtain raw meal, wherein the weight ratio of ammonium sulfate to alumina in fly ash is 5:1; heat the raw meal to 450°C , keep warm for 1h, make clinker, exhaust gas for water absorption to make ammonia water, and use for aluminum sulfate decomposition; clinker is dissolved in hot water for 0.5h, aluminum enters the solution in the form of aluminum sulfate, and silicon stays in the residue to form High-silicon slag; after dissolution, the slurry is separated by solid-liquid and countercurrent washed, the liquid is aluminum sulfate solution, and the solid is high-silicon slag; add ammonia g...

Embodiment 2

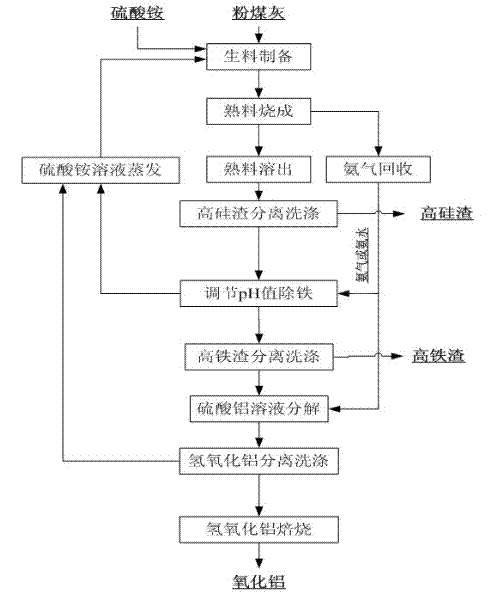

[0024] Take 1000g of the raw material fly ash composed in Example 1, and wet mix the raw material fly ash and ammonium sulfate circulating fluid to obtain raw meal, wherein the weight ratio of ammonium sulfate to aluminum oxide in the fly ash is 6:1; Heat the raw material to 500°C and keep it warm for 0.5h to make clinker. After the exhaust gas is dried and dedusted, it is sent to the aluminum sulfate decomposition process with a compressor; the clinker is dissolved in hot water for 1 hour, and the aluminum enters in the form of aluminum sulfate. solution, silicon remains in the residue to form high-silicon slag; after dissolution, the slurry undergoes solid-liquid separation and countercurrent washing, the liquid is aluminum sulfate solution, and the solid is high-silicon slag; ammonia gas recovered by adding ammonia to the aluminum sulfate solution is adjusted. When the pH value reaches 2.5, ferric hydroxide is precipitated. After the high-iron slag is separated, ammonia gas ...

Embodiment 3

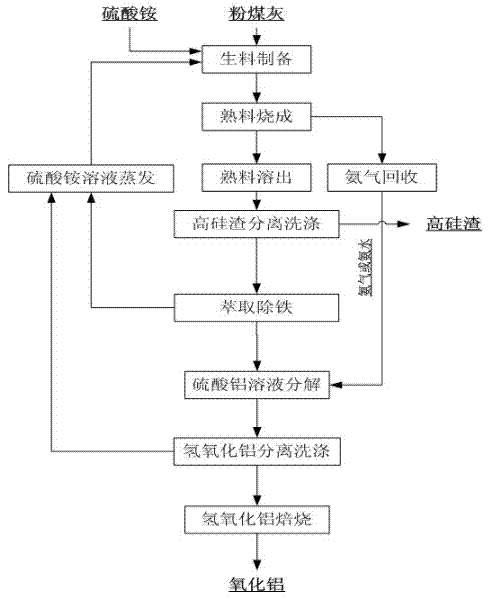

[0026] In Example 2, the gas produced by clinker burning is absorbed by the high-silicon slag washing liquid to make ammonia water, and ammonia gas is added to the aluminum sulfate solution to recover the ammonia water obtained, and the pH value is adjusted to 3.5 to precipitate ferric hydroxide and separate hydrogen After iron oxide, continue to add ammonia in the solution to obtain aluminum hydroxide and ammonium sulfate solution; Others are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com