Converter fluxing medium with LF refinery cinder as raw material and production method thereof

A technology for refining slag and its production method, which is applied in the field of converter flux and its production using LF refining slag as raw material, can solve problems such as difficulty in direct utilization and large differences in chemical composition of bulk materials, etc., to ensure smelting effect and reduce The effect of back drying and fast slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

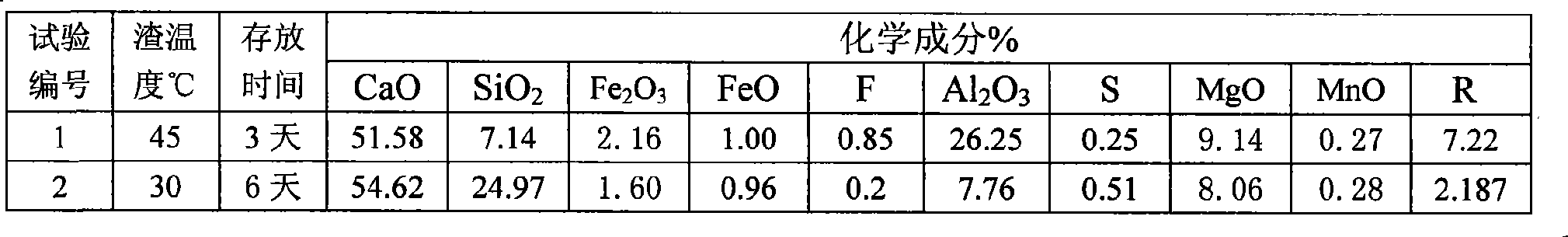

[0017] In the present invention, two groups of LF furnace refining slag samples stored for 3 days (when the measured temperature is 45° C.) and 6 days (when the measured temperature is 30° C.) are respectively used as base samples, and are mixed, screened, and magnetized respectively. Part of the slag and iron particles were removed, and two groups of silt-like material samples with a uniform texture of less than 10 mm were obtained as raw materials for production.

[0018] The chemical compositions of the two groups of refining slags are shown in Table 1.

[0019] Table 1. Test refining slag temperature and chemical composition

[0020]

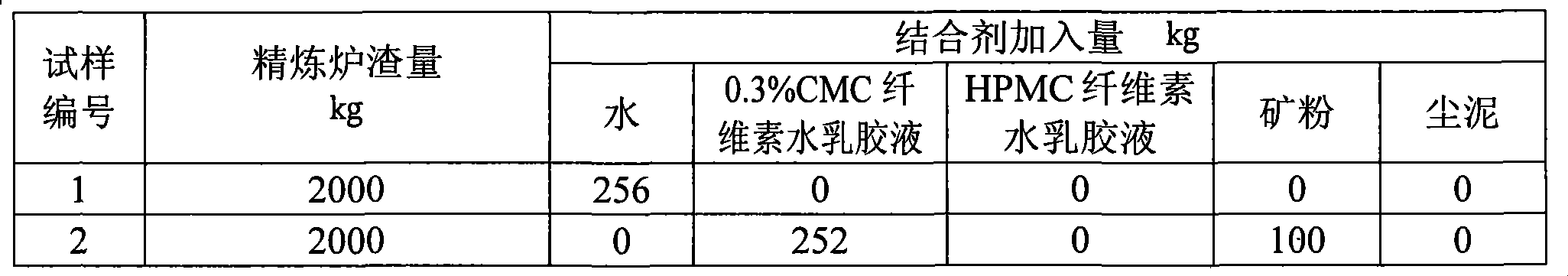

[0021] Take 2000Kg of each of the above two groups of samples and send them to the wheel mill respectively. The first group of samples is mixed with 256Kg of pure water, and the second group of samples is mixed with 252Kg of 0.3% CMC cellulose water emulsion. Table 2.

[0022] Table 2, ingredient composition

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com