GR reinforced magnesium alloy-based composite material wire and preparation method

A composite material and magnesium alloy technology, which is applied in the preparation of magnesium alloy-based composite material wire, and in the field of magnesium alloy-based composite material wire, can solve the problems of GR easy reunion or reconstruction, cumbersome preparation process, and component segregation. Achieve the effects of avoiding micro-cracks at the interface, expanding the application field, and high anti-friction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

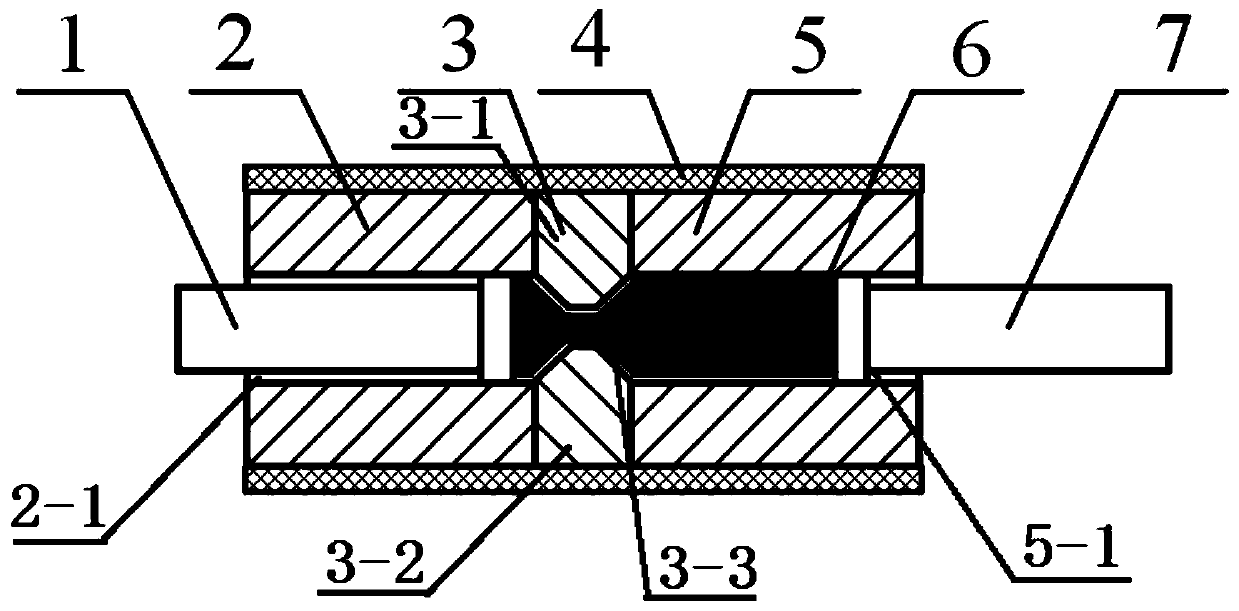

[0039] The present invention provides a method for preparing the above-mentioned GR reinforced magnesium alloy-based composite material wire, which includes the following steps:

[0040] Step 1, high energy ball milling:

[0041] Weigh the following raw materials according to weight percentages: 0.5-1.5% of GR powder, the balance being magnesium alloy powder, and the sum of the weight percentages of the above components is 100%;

[0042] Place GR powder and magnesium alloy powder in a high-energy ball mill at 70-100 rpm under the protection of argon gas for 25-36 hours;

[0043] In step 1, the GR powder is a single-layer graphene dry powder; the magnesium alloy powder is 250-400 mesh, any standard grade is AZ series or ZK series magnesium alloy powder, specific magnesium alloy powder or rare earth magnesium alloy powder as required.

[0044] In step 1, the ball-to-material ratio of the ball mill is 6:10.

[0045] The grinding balls used in step 1 are: 12mm diameter grinding balls and cap...

Embodiment 1

[0058] 250 mesh AZ91 alloy powder is selected as the matrix of the composite material, weighed according to the weight ratio, 0.5% GR powder, the rest is 250 mesh AZ91 powder, and the sum of the weight percentages of the above components is 100%. Use Φ12mm grinding balls and capsule grinding balls, the number of grinding balls and capsule grinding balls are the same, and the weight of the grinding balls is 60% of the weight of GR and AZ91 powder to be ball milled, that is, the ball-to-battery ratio of the ball mill is 6:10.

[0059] Put the above-mentioned powders and grinding balls into a ball mill tank together, and mix the powders in a high-energy ball mill at a speed of 70 rpm under the protection of argon for 25 hours. Mix uniformly through ball milling machine to avoid GR reconstruction and multilayering;

[0060] Put the completely mixed and uniform GR and AZ91 powder mixture into a special reciprocating extrusion device at 250°C with a reciprocating extrusion ratio of 10 an...

Embodiment 2

[0063] Select 400 mesh ZK60 alloy powder as the matrix of the composite material, weigh it according to the weight ratio, 1% GR powder, and the rest is 400 mesh ZK60 powder, and the sum of the weight percentages of the above components is 100%. Use Φ12mm grinding balls and capsule grinding balls, the number of grinding balls and capsule grinding balls is the same, and the weight of the grinding balls is 60% of the weight of GR and ZK60 powder to be ball milled, that is, the ball-to-battery ratio of the ball mill is 6:10.

[0064] Put the above-mentioned powders and grinding balls into a ball mill tank together, and mix the powders in a high-energy ball mill under the protection of argon at a speed of 100 rpm for 36 hours. Mix uniformly through ball milling machine to avoid GR reconstruction and multilayering;

[0065] Put the completely mixed and uniform GR and ZK60 powder mixture into a special reciprocating extrusion device. At 300°C, the reciprocating extrusion with an extrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com