G-C3N4/CNT nanohybrid material modified PPESK lubricating film and preparation method thereof

A technology of nano-hybrid materials and lubricating films, which is applied in the field of membrane material preparation, can solve the problems of unsatisfactory high-performance lubricating materials, low PPESK load capacity, and inability to meet industrial needs, etc., to improve material mechanical and wear resistance properties, improve Tribological performance, the effect of excellent tribological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: g-C 3 N 4 preparation of

[0028] Weigh 3 g of urea and grind it in a mortar until it is evenly mixed. Under the protection of nitrogen, it was put into a covered alumina crucible, the temperature was gradually raised, and it was calcined in a tube furnace. The temperature was raised from 350°C to 550°C in 90 minutes, and kept for 120 minutes. Naturally cooled to room temperature, the calcined product was taken out, washed several times with deionized water and alcohol, centrifuged and dried to obtain g-C 3 N 4 nanomaterials.

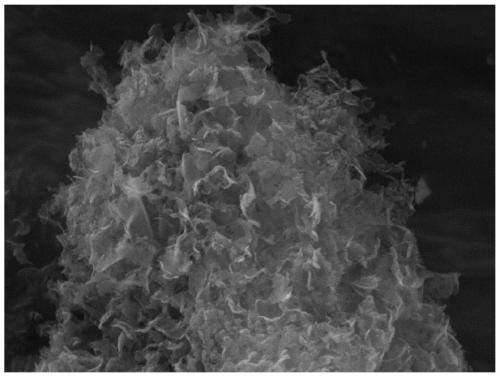

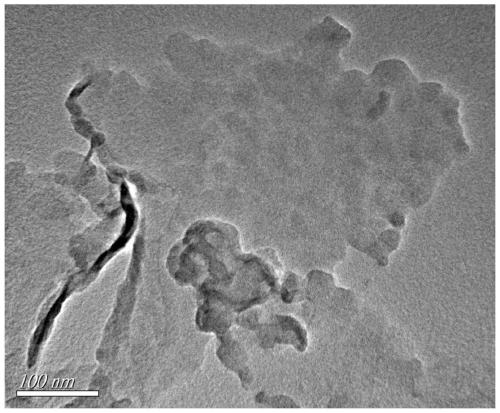

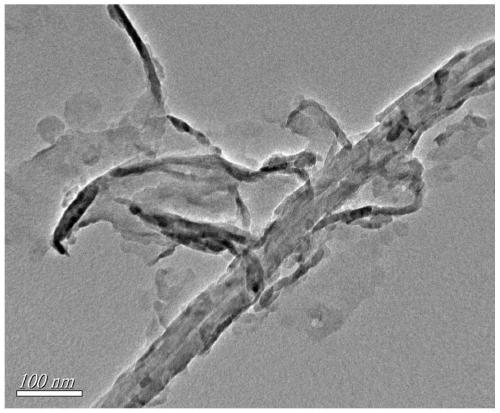

[0029] figure 1 with 2 for g-C 3 N 4 SEM and TEM topography of nanomaterials, from which it can be clearly seen that the prepared g-C 3 N 4 Nanomaterials are transparent, curled two-dimensional thin-layer structures. Figure 5 for g-C 3 N 4 and g-C 3 N 4 / CNT nano-hybrid material X-ray diffraction pattern. It can be seen from the figure that g-C 3 N 4 There are two characteristic diffraction peaks at 12.7° and 27.5°,...

Embodiment 2

[0030] Example 2: g-C 3 N 4 / CNT nano-hybrid material preparation

[0031] Weigh 8 g of urea and 0.036 g of CNT, grind and mix them evenly in a mortar. Under the protection of nitrogen, the mixture was placed in an alumina crucible with a cover, the temperature was gradually raised, and it was calcined in a tube furnace. The temperature was raised from 350° C. to 550° C. in 100 minutes, and kept for 100 minutes. Naturally cooled to room temperature, the calcined product was taken out, washed several times with deionized water and alcohol, centrifuged and dried to obtain g-C 3 N 4 / CNT nano-hybrid materials.

Embodiment 3

[0033] (1) g-C 3 N4 / CNT nano-hybrid material preparation:

[0034] Weigh 9 g of urea and 0.04 g of carbon nanotubes, grind and mix them evenly in a mortar. Under the protection of nitrogen, the mixture was placed in an alumina crucible with a cover, and the temperature was gradually increased, and calcined in a tube furnace. The program was: the temperature was raised from room temperature to 330 ° C within 100 minutes, and kept for 120 minutes, and then, The temperature was raised from 330°C to 500°C within 90 minutes and kept at this temperature for 110 minutes. Naturally cooled to room temperature, the calcined product was taken out, washed several times with deionized water and alcohol, centrifuged and dried to obtain g-C 3 N 4 / CNT nano-hybrid materials.

[0035] (2) g-C 3 N 4 Preparation of PPESK lubricating film modified by / CNT nano-hybrid material:

[0036] Take 4.0g of PPESK powder and dissolve it in 50mL of DMA organic solvent, and stir it ultrasonically to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com