sw-cnts and n-sicp reinforced magnesium alloy workpiece and method

A technology for strengthening magnesium alloys and magnesium alloys, which is applied in the field of preparation of the SW-CNTs and N-SiCp reinforced magnesium alloy workpieces, can solve the problems of restricting the performance of SW-CNTs short fibers and easy entanglement, and achieve weight reduction, The effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

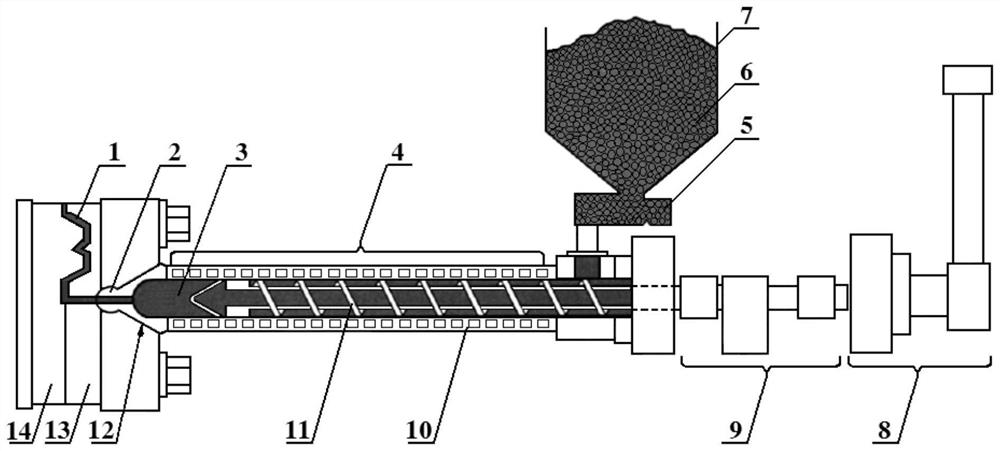

[0045] Weigh the following raw materials according to weight percentage: SW-CNTs short fiber content is 0.5%, N-SiCp particle content is 1%, the rest is 650 mesh AZ91 powder, the sum of the weight percentages of the above components is 100%; choose 650 mesh AZ91 alloy powder is used as the matrix of the composite material, SW-CNTs are fibers with a length of 2 μm, and the particle size of N-SiCp particles is 50 nm; B of Φ8 mm is used 4 C Grinding Balls and Capsule Grinding Balls, B 4 C grinding balls and capsule grinding balls have the same number, B 4 The ratio of the total weight of C grinding balls and capsule grinding balls to the weight of the mixed powder is 1:1.

[0046] The above-mentioned mixed powder and balls were put into a ball mill tank together, and the mixed powder was ball-milled for 36 hours in a horizontal high-energy ball mill at 300 rpm under the protection of argon.

[0047] After ball milling, SW-CNTs short fibers, N-SiCp particles and magnesium alloy ...

Embodiment 2

[0050] Weigh the following raw materials according to weight percentage: SW-CNTs short fiber content is 1%, N-SiCp particle content is 3%, and the rest is 650 mesh AZ80 powder, the sum of the weight percentages of the above components is 100%; choose 650 mesh AZ80 alloy powder is used as the matrix of composite materials, SW-CNTs are fibers with a length of 3 μm, and the particle size of N-SiCp particles is 50 nm. 4 C Grinding Balls and Capsule Grinding Balls, B 4 C grinding balls and capsule grinding balls have the same number, B 4 The ratio of the total weight of C grinding balls and capsule grinding balls to the weight of the mixed powder is 1:1.

[0051] The above-mentioned mixed powder and balls were put into a ball mill tank together, and the mixed powder was ball-milled for 36 hours in a horizontal high-energy ball mill at 300 rpm under the protection of argon.

[0052] After ball milling, SW-CNTs short fibers, N-SiCp particles and magnesium alloy powder, which are co...

Embodiment 3

[0056] Weigh the following raw materials according to weight percentage: SW-CNTs short fiber content is 1.5%, N-SiCp particle content is 5%, and the rest is 650-mesh ZK60 powder. The sum of the weight percentages of the above components is 100%. 650-mesh ZK60 alloy powder is selected as the matrix of the composite material, SW-CNTs are fibers with a length of 5 μm, the particle size of N-SiCp particles is 100 nm, and B of Φ8 mm is used 4 C Grinding Balls and Capsule Grinding Balls, B 4 C grinding balls and capsule grinding balls have the same number, B 4 The ratio of the total weight of C grinding balls and capsule grinding balls to the weight of the mixed powder is 1:1.

[0057] The above-mentioned mixed powder and balls were put into a ball mill tank together, and the mixed powder was ball-milled for 36 hours in a horizontal high-energy ball mill at 300 rpm under the protection of argon.

[0058] After ball milling, SW-CNTs short fibers, N-SiCp particles and magnesium allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com